Working with Wire

Wire Thickness

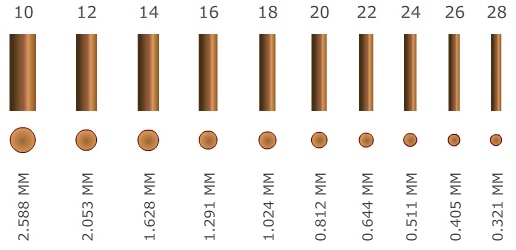

The term ‘gauge’ is used to define the diameter of the wire. The gauge of a wire is used to determine the amount of current a wire can safely handle. Wire gauge can refer to both electrical and mechanical. This tutorial will only cover electrical. There are two main systems for measuring gauge, American Wire Gauge (AWG) and Standard Wire Gauge (SWG). The differences between the two are not critical to this guide.

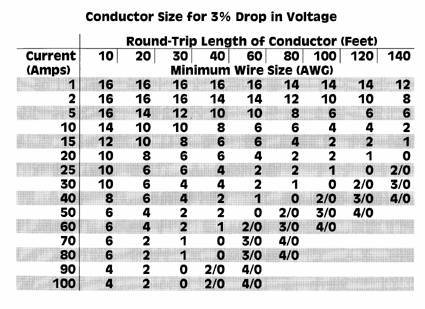

The amount of current that a wire can carry depends on a few different factors, for example the composition of the wire, wire length, and condition of the wire. In general, thicker wire can carry more current.

Here at SparkFun, we typically use 22 AWG wire for prototyping and breadboarding. When using a breadboard or PCB, solid core is perfect because it fits nicely into the holes. For other prototyping/building involving soldering, the stranded core is #1, just be sure not to let too much current run through a single wire. It will get hot and could melt!

SparkFun carries a variety of both solid and stranded 22 AWG wire.

However, there is still an option to use 30 AWG wire wrap if you need to go smaller.

Wire Wrap Wire - Blue (Solid, 30AWG, 100ft)

PRT-14913

Wire Wrap Wire - White (Solid, 30AWG, 100ft)

PRT-14914 |

|

|

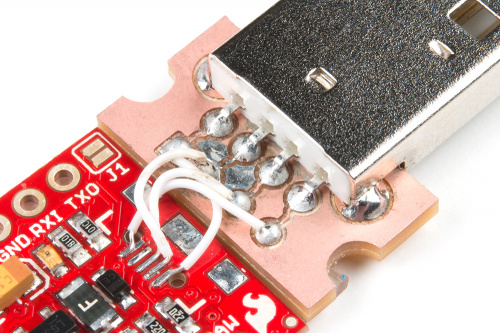

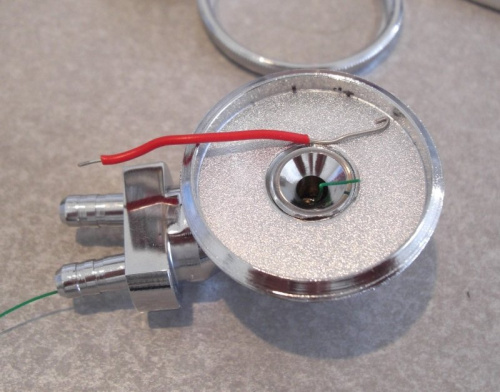

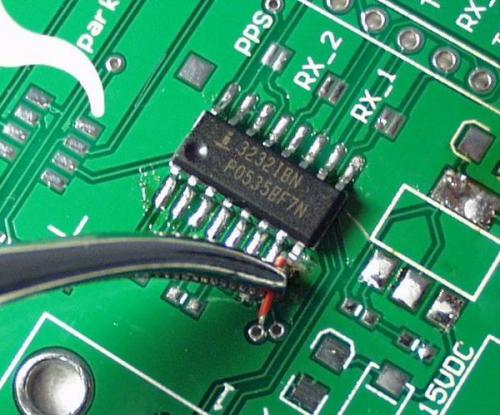

| Wire Wrap connecting to a PCB's small SMD pins that are broken out on the Hardware Mouse Jiggler. | Wire Wrap used in projects with small spaces of the Heartbeat Straight Jacket. | "Green" Wire Repairs with a bad PCB design or damaged pad. |