Building an Autonomous Vehicle: The Batmobile

Contributors:

Nate

Nate

Wire

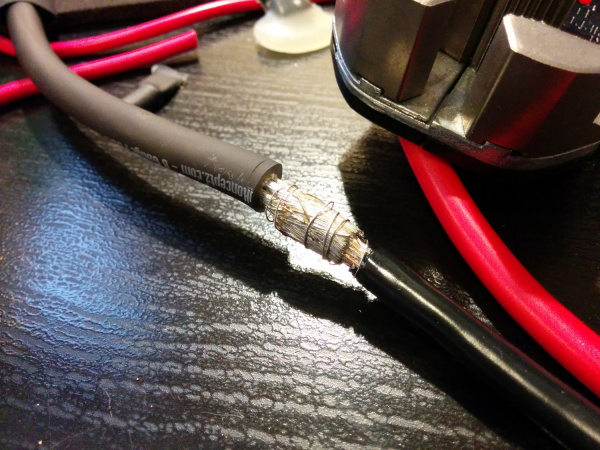

Soldering large-gauge wire

We originally spec’d out some really nice, super flexible silicone-sheathed 8AWG wire for power distribution. I don’t think we would do this again; 10AWG would have been fine, and probably even 12AWG. As 8-gauge is far less common, the wire and connectors are more expensive, and the larger gauge wire takes a lot more soldering heat -- it’s just a pain to work with. If you need the current capacity, go for it, but for our extremely zippy, 48V 20A vehicle, 8-gauge wire was overkill.

If you decide to use super flexible, large gauge wire, spend some time on the internet reading about how to solder this type of wire.

The best technique I found:

- Make sure you’ve got heat shrink in place

- Turn your soldering iron up to 425C (way hotter than the 325C usually needed)

- Push the ends of wire together

- Wrap tightly with 30AWG wire wrap wire

- Liberally apply flux

- Heat and insert lots of solder until the joint turns silver

Here’s a good video demonstrating this technique: