Working with Wire

Stranded vs Solid Core Wire

Wire can come in one of two forms: solid or stranded core.

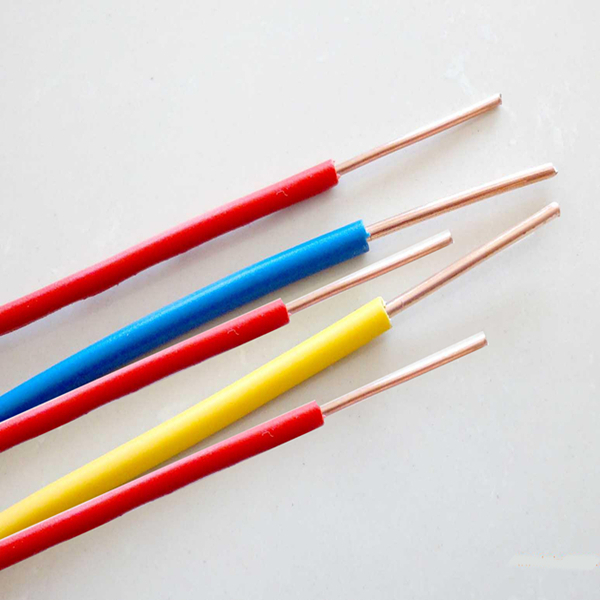

Solid Core

Solid wire is composed of a single piece of metal wire, also known as a strand. One very common type of solid wire is known as wire wrap.

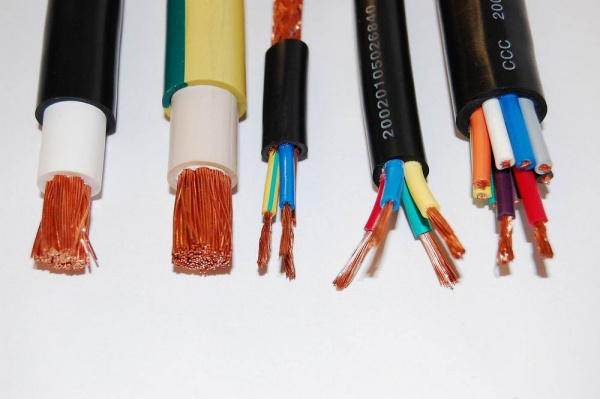

Stranded Core

Stranded wire is composed of many pieces of solid wire all bundled into one group. It is much more flexible than solid wire of equal size.

Applications of Solid and Stranded Core Wire

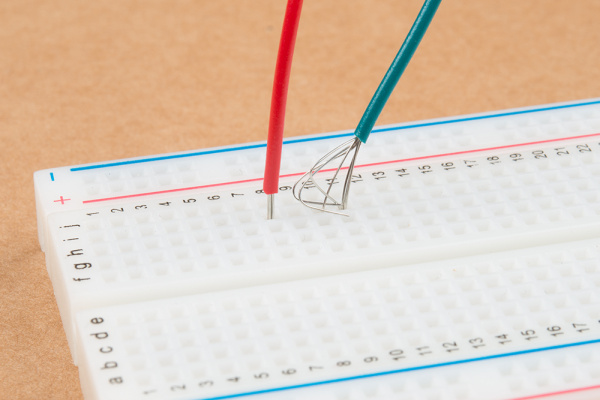

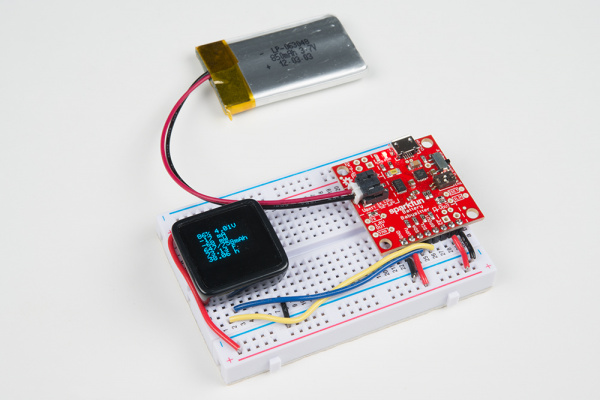

Since stranded wire is more flexible than solid core wire of equal size, it can be used when the wire needs to move around frequently, in a robot arm for example. Conversely, solid wire is used when little or no movement is needed, such as prototyping circuits on a breadboard or protoboard. Using solid core wire makes it easy to push the wire into a breadboard and plated through holes of a printed circuit board.

|

|

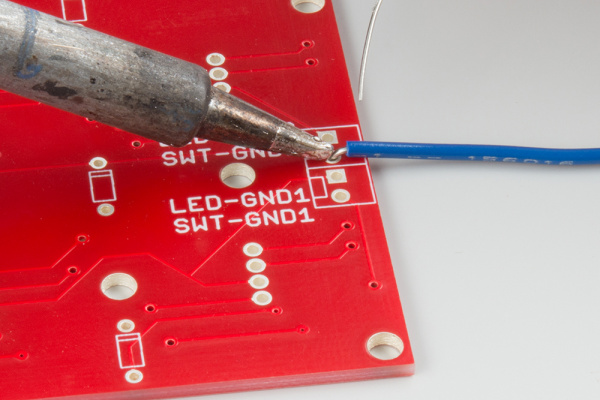

| Solid Core Wire Used in a Breadboard with the Battery Babysitter | Solid Core Wire Soldered into a Plated Through Hole with the Button Pad Breakout Board |

Trying to use stranded wire on a breadboard or plated through hole can be very difficult depending on the thickness as the strands want to separate as they are pressed in.

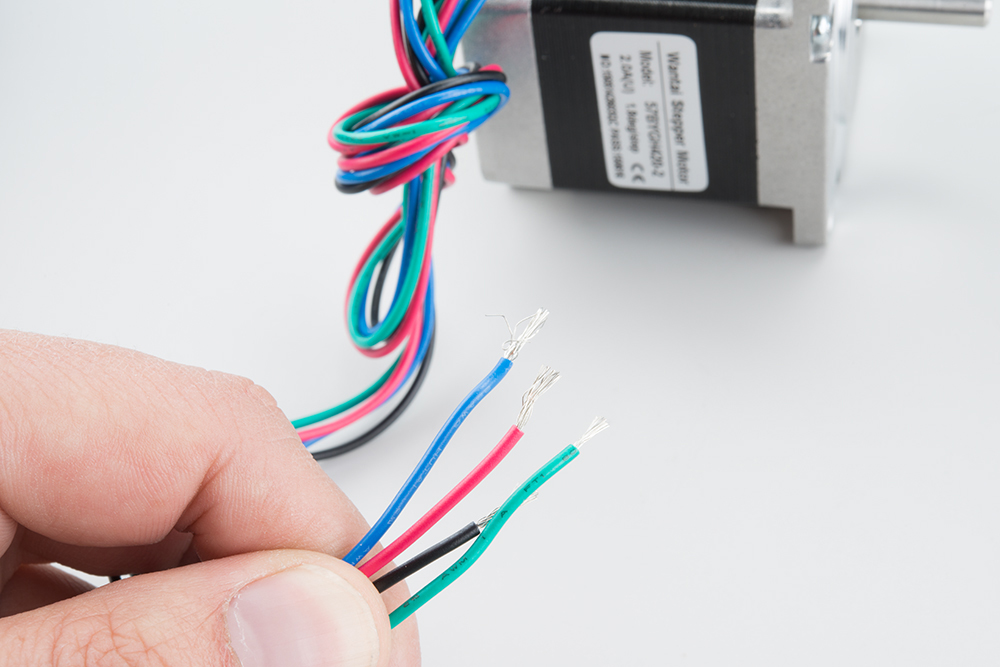

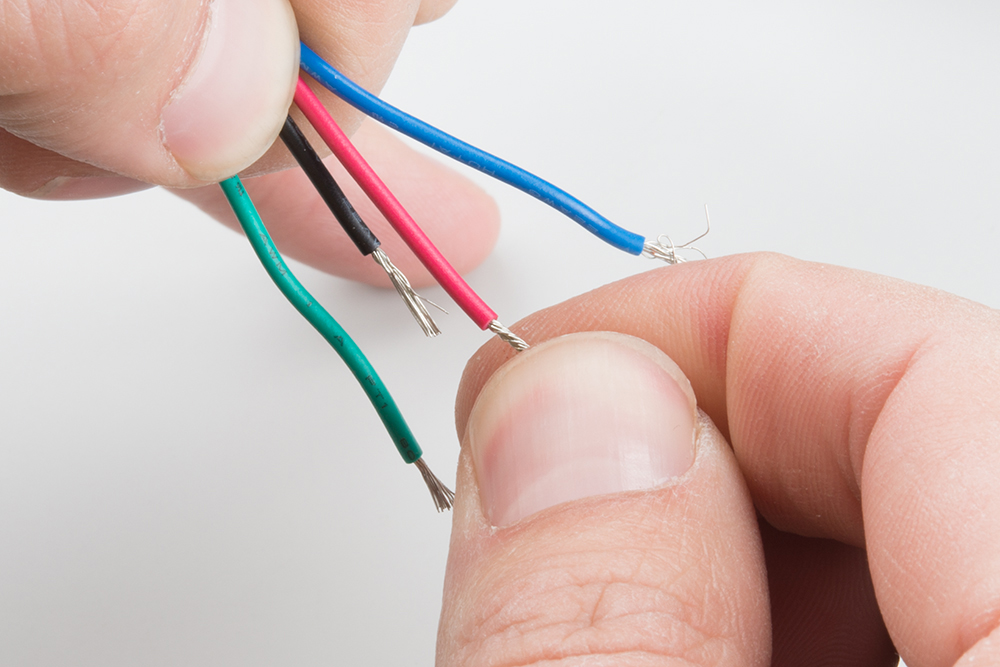

The image on the left shows the wire strands being twisted by giving them about 180 degrees of twist along the length of the strip. The image on the right shows the wires being tinned with soldered. Apply excess solder to allow the flux to work, and pull the extra solder off with the iron yielding a solid cylinder of wire.

|

|