Working with Wire

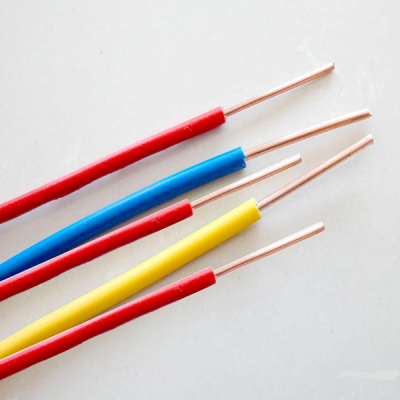

How to Strip a Wire

Safe, durable electrical connections begin with clean, accurate wire stripping. Removing the outer layer of plastic without nicking the wires underneath is critical. If a wire does get nicked, the connection may break or an electrical short may occur.

The Tools

Manual Wire Stripper

A simple manual wire stripper is a pair of opposing blades much like scissors. There are several notches of varying size. This allows the user to match the notch size to the wire size, which is very important for not damaging the wires. Depending on the manufacturer, there may be additional features that include a locking mechanism, have an ergonomic handle, and the ability to cut screws.

Although a knife would also strip the wires, it may also damage the wire by nicking the metal or cutting into it. Using a knife to strip wire is also really dangerous! The knife can easily slip and cause wicked injuries.

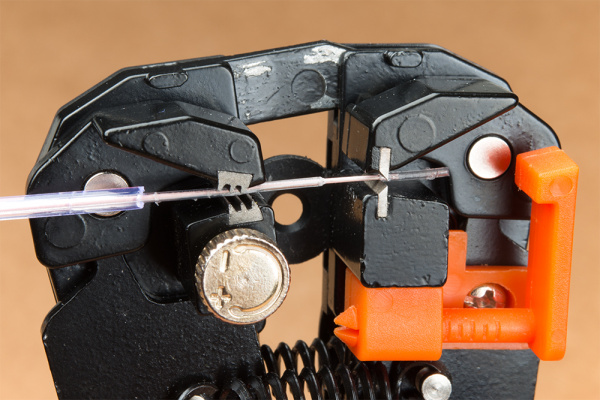

Self-Adjusting Wire Stripper

There are also self-adjusting wire strippers that automatically strip wire by placing a wire in the middle of the teeth and squeezing the handle. These take almost any wire and perfectly strip the wires every time. Depending on the manufacturer, there may be additional features included to cut or crimp insulated/non-insulated wires.

Self-Adjusting Wire Strippers

TOL-14872Wire Wrap Tool

If you are using a wire wrap tool to wrap a wire around a pin, there may already a built-in stripper blade in the middle to strip the thin wire. Simply place the wire between the blades and pull.

Wire Wrap Tool

TOL-14915Stripping the Wire with Manual Wire Strippers

By simply squeezing the handles of a manual wire stripper about 1/4" from the end of the wire or the desired length, using the correct notch on the tool, and then twisting it slightly, the insulation will be cut free.

Then by pulling the wire strippers towards the end of the wire, the insulation should slide right off of the wire.

Stripping Cable Wires with Self-Adjusting Wire Strippers

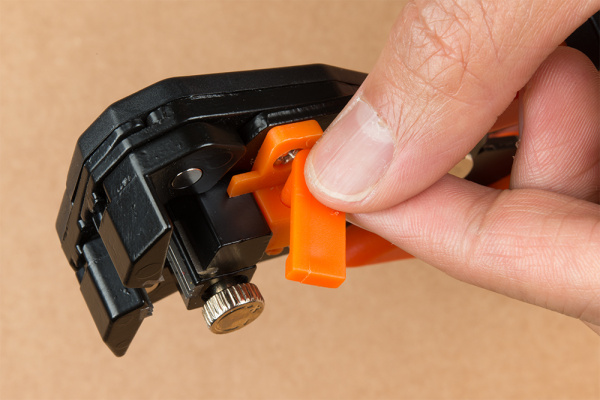

The special self-adjusting wire strippers makes it easy to remove sheaths and stripping multiple insulated wires. For this example, we are going to wire strip a power cable. Place the end of the cable between the tool's wire cutter to cut. When ready, squeeze the handles tp cut the cable end.

Turn the plastic guide away from the head and slide it out to adjust the wire length to cut. Reposition the plastic guide when you are satisfied with the wire length. For cables, you may want to strip more than the recommended guide.

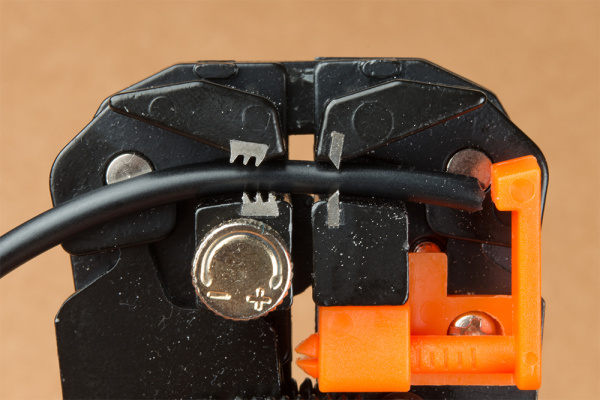

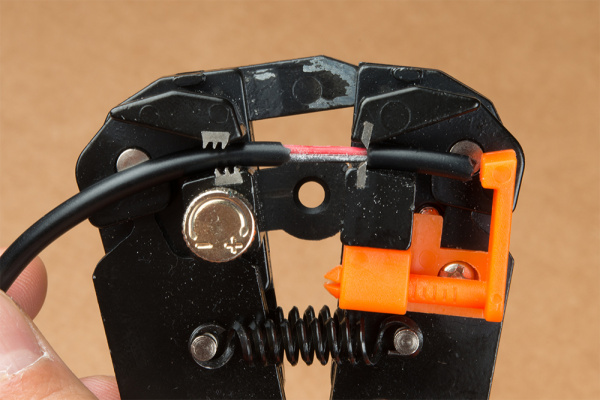

Insert the cable between the jaws. If necessary, increase/decrease the tension of the jaw using the tension knob as necessary depending on the cable and wire size.

While holding the cable in place, squeeze the handles to strip the sheath from the cable.

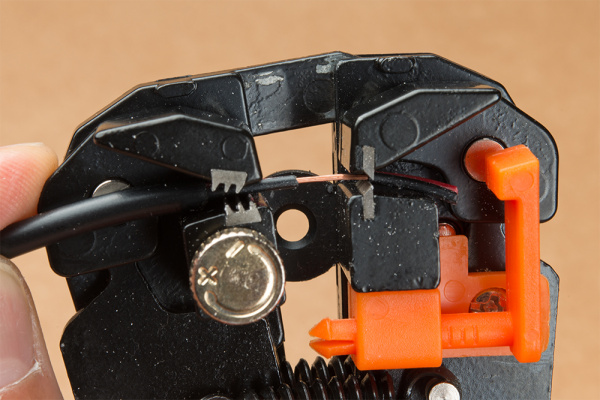

After sliding the sheeth from the cable, place the internal wires between the teeth. Adjust the tension of the jaw using the tension knob as necessary depending on the cable and wire size.

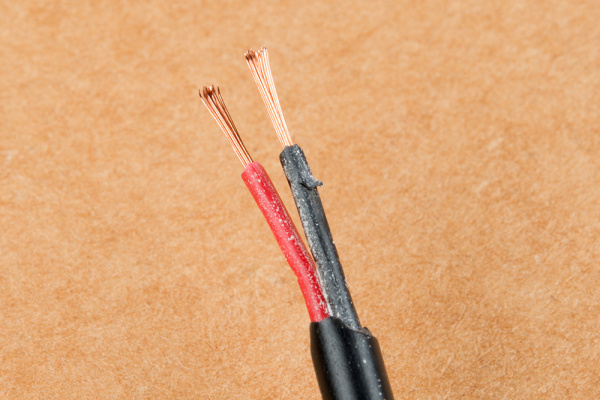

When finished, your cable wires should be perfectly stripped!

Tips, Tricks, and Hints

It is important to match the size of wire to the correct notch in the stripper. If the notch is too large, the wire will not get stripped. If the notch is too small, there is a risk of damaging the wire. Using an undersized notch means the strippers will close too far, digging into the wire underneath. With stranded wire, the tool will cut off the outer ring of wires, decreasing the total diameter of wire and reduce the strength of the wire. A nick in solid core wire will severely reduce the strength and flexibility of the wire. The likelihood of the wire breaking upon being bent increases significantly.

If a wire does accidentally get a nick in it, the best plan of action is to cut the damaged part of the wire off and try again.