Interactive 3D Printed LED Diamond Prop

3D Print It

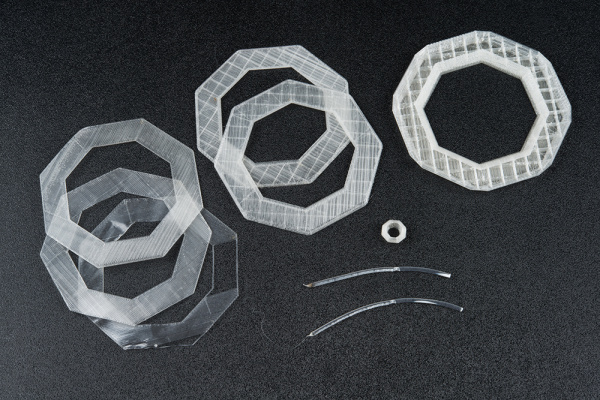

I do not have much experience with 3D printing and modeling complex shapes. Luckily, there were a few models of diamonds listed online that I found to save on time. After browsing Thingiverse, the model that I found appealing was "Oopee's" diamond lampshade. Head over to the thing and download to print the model of your size.

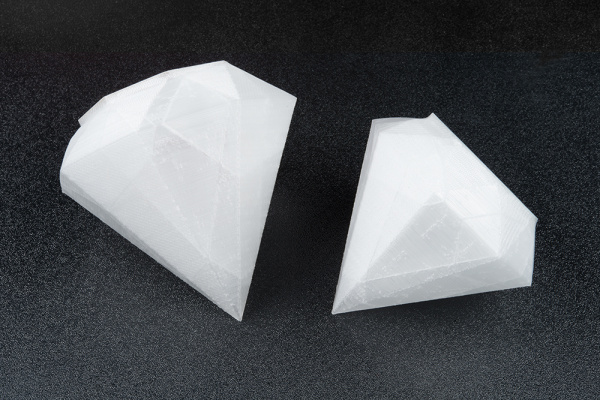

Printing a medium size diamond was sufficient and easy to see on stage as a prop. Caution is advised for printing large scale models due to time and material used.

A Small World, After All?

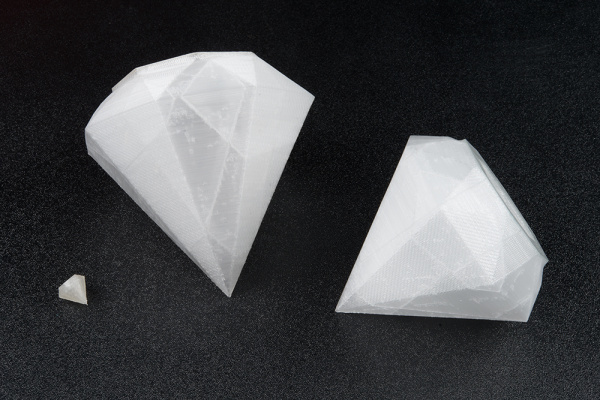

To start, I printed a small scale version of the diamond lampshade in Cura to see how it would look. The diamond on the bottom left shows the first print of the diamond against the larger prints. Satisfied with the small print. I decided to go bigger!

Big Trouble in Little... Nozzle

I decided to go big and start printing the diamond. Unfortunately, I ran into an issue once the print started. The 3D printer's extruder kept getting clogged causing the print to fail. I tried using a needle to clean the nozzle and manually feeding more material in the extruder. This fixed the problem temporarily but the issue kept coming up.

Doing a search online and inspecting the setup, there were a few possible reasons why this might have been happening:

- incorrect idler tension

- speed of the print

- poor quality filament

- filament tangled in spool

- clogged extruder

A clogged extruder seemed to be a plausible explanation of what was going on. Checking in with someone more knowledgeable about 3D printing at SparkFun, I headed over to a mechanical engineer for advice and showed him a few of the stripped filaments as shown below.

He was able to confirm my assumption. With the technical support's 3D printer being used communally, he explained that the clogged extruder was probably due to either:

- impurities from poor quality filament (as stated above)

- changing filament material (PLA to ABS)

Acetone Bath

So how would you fix the clogged extruder? An acetone bath! This was a last resort considering my previous efforts had failed. After removing the tool head from the Lulzbot 3D printer, we carefully removed the hot end's nozzle using some pliers. And by careful, we had to avoid breaking the thermistor attached to the hot end. Once removed, a glass jar was filled just enough to submerge the nozzle tip in acetone and cleaned with a Q-tip over the course of 2 days.

Insufficient Filament and Recycling a Failed Print

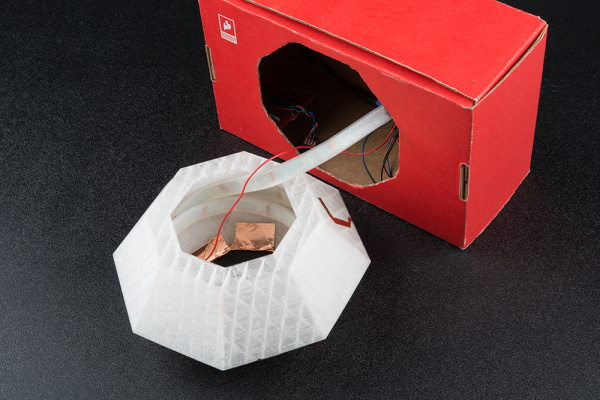

While the nozzle was being cleaned, our mechanical engineer was kind enough to allow me to use the mechanical engineering's 3D printer. Off I went to print the big diamond. However, I ran into yet another problem. I did not have enough material! I was too ambitious and did not keep track of the amount of material I had available. 30 hours into the print, I ran out of material as you can see from the image below. While the print failed, I decided to recycle the failed print by making it into a diamond holder.

A Happy Medium

Success! On my 10th attempt with a replenished supply of clear filament, I was able to successfully print a diamond. I found a happy medium of printing a diamond. After learning some lessons from the failed prints, I reduced the amount of material used between the walls and reduced the size of the model to a smaller size. Confident in the print, I printed another diamond slightly larger.