RedBot Assembly Guide Rev 02

This Tutorial is Retired!

This tutorial covers concepts or technologies that are no longer current. It's still here for you to read and enjoy, but may not be as useful as our newest tutorials.

**Wheel Encoder**

Read on if you are using the Wheel Encoder Kit. If not, skip to the next section.

The Wheel Encoder Kit is a simple add-on to any wheeled robot that can help measure the speed or distance the chassis travels. For the RedBot, we found that it is easier to use this wheel encoder.

Locate the Following:

| 2x Motor | 2x 4" Zip-Tie | 1x Wheel Encoder Kit |

|

|

|

Adding the Wheel Encoder to Motors

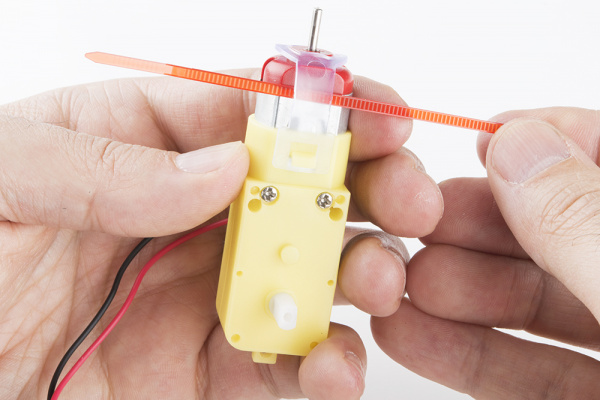

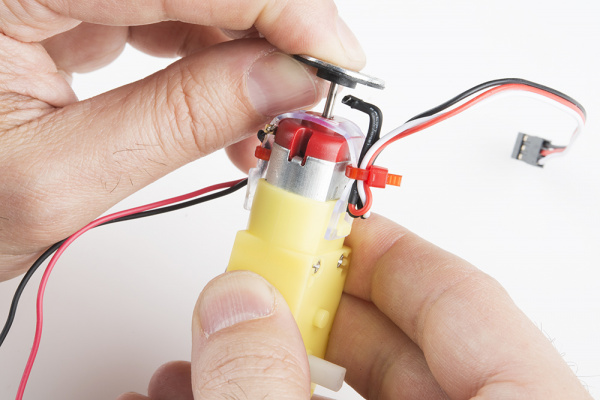

First, you will want to grab a 4" zip-tie (a smaller zip-tie will work as well). Push the zip-ties inside the opening between the clear plastic and the motor. Make sure the zip-tie is going through the opening that isn't on the same side as the black and red wires soldered to the motor.

Next, slightly close the zip-tie. Make sure not to fully tighten the zip-tie yet.

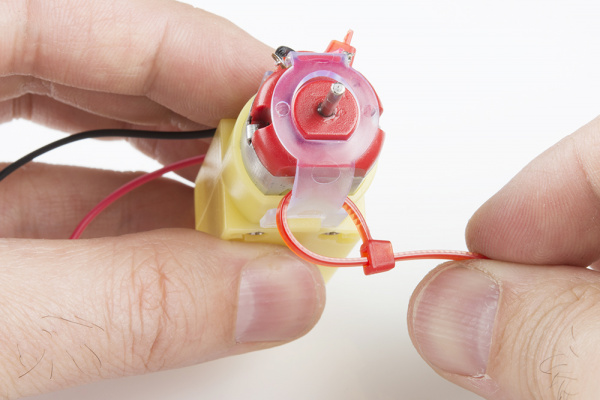

Grab the hall effect sensors, terminated with 150mm cables and a 3-pin female servo header, from the Wheel Encoder Kit. Bend the hall effect sensor side downward at a 90 degree angle, as shown in the photo below.

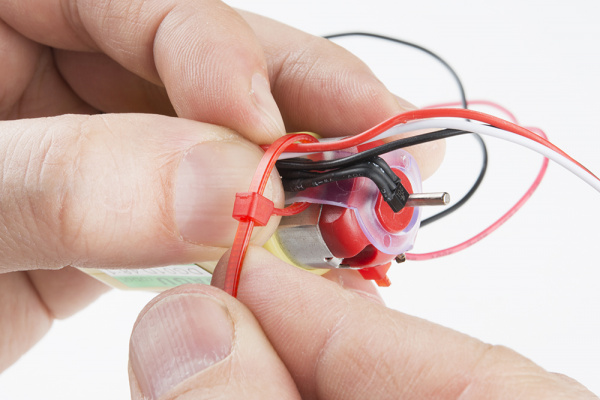

Bend the hall effect sensors cable again, so it is laying horizontal on itself. Bending the cable again makes this setup sturdier and the hall effect sensor less likely to move around.

Place the bent hall effect sensors cable through the zip-tie loop created earlier. You will want to line up and point the hall effect sensor to the middle of the shaft of motor.

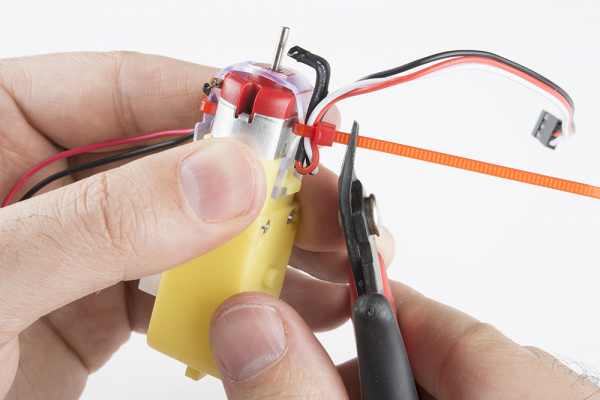

Tighten the zip-tie firmly. Make sure the hall effect sensor is still pointing inward to the shaft of the motor. Using flush cutters, cut the zip-tie's extra end hanging out.

Add the neodymium 8-pole magnet with the rubber hub to the shaft of motor. The hall effect sensor should be horizontal.

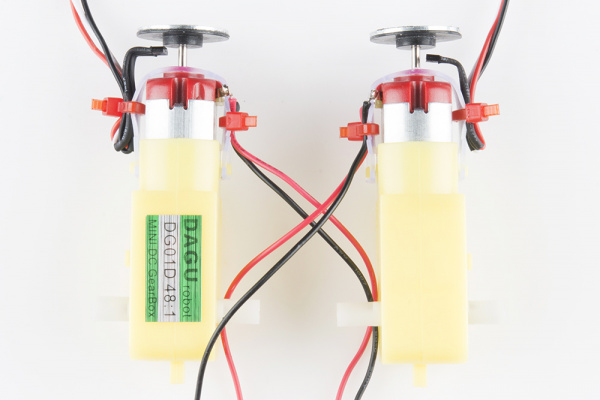

Go ahead and do the same the wheel encoder setup to the other motor.

Double check the hall effect sensors are nice and lined up between the motor and magnet with the rubber hub. Also be sure that it is pointed inward toward the shaft of the motor.