MicroMod Main Board Hookup Guide

Introduction

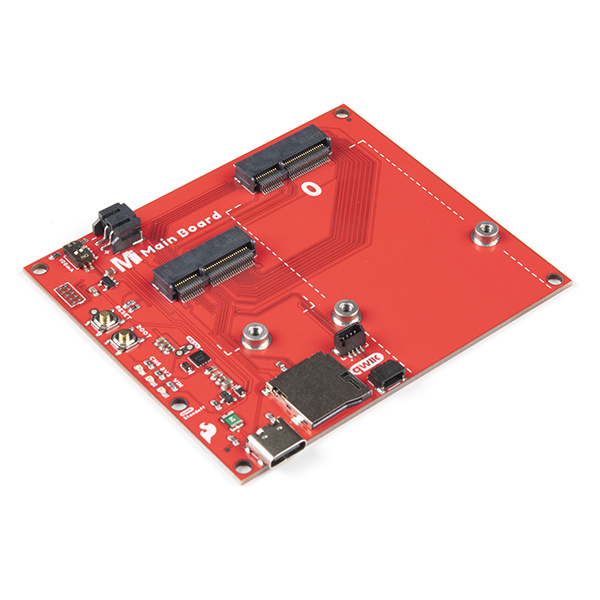

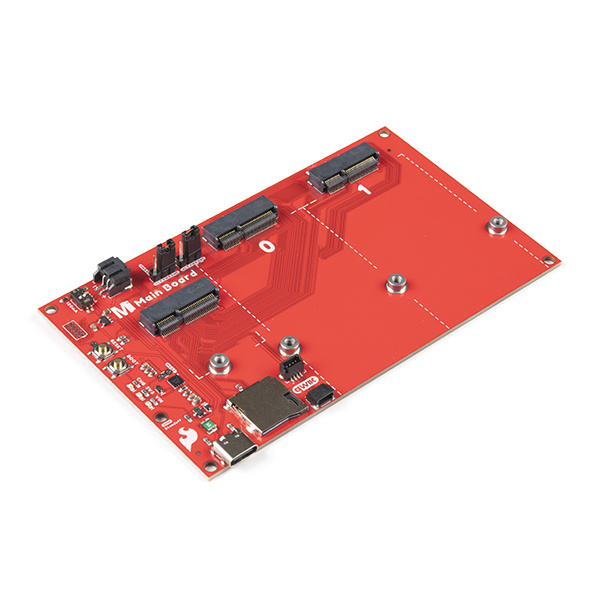

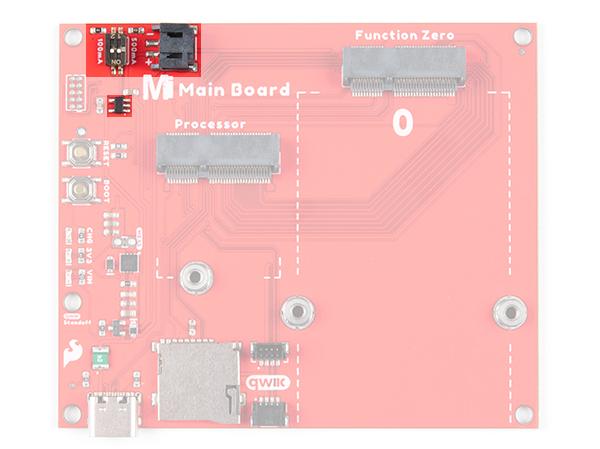

The MicroMod Main Board - Single and Double are specialized carrier boards that allow you to interface a Processor Board with a Function Board(s). The modular system allows you to add an additional feature(s) to a Processor Board with the help of a Function Board(s).

SparkFun MicroMod Main Board - Single

DEV-18575SparkFun MicroMod Main Board - Double

DEV-18576Required Materials

To follow along with this tutorial, you will need the following materials at a minimum. You may not need everything though depending on what you have. Add it to your cart, read through the guide, and adjust the cart as necessary.

SparkFun MicroMod Main Board - Single

DEV-18575MicroMod Main Board

To hold the processor and function boards, you will need one Main board. Depending on your application, you may choose to have either one or two function boards.

SparkFun MicroMod Main Board - Single

DEV-18575SparkFun MicroMod Main Board - Double

DEV-18576MicroMod Processor Board

There are a variety of MicroMod Processor Boards available to choose from. You will probably want to avoid having the same Processor and Function Board since there is an ESP32 on both types of boards.

MicroMod Function Board

To add additional functionality to your Processor Board, you'll want to include one or two function boards when connecting them to the Main Board. Make sure to check out the catalog for other function boards.

Tools

You will need a screw driver to secure the Processor and Function boards. To set the charge rate, you will need a precision screw driver (or a tiny, rounded object). The pocket screwdriver set is an excellent option. For users using a microSD card and want to easily read the contents of the memory card, you will need a microSD card adapter or USB reader.

microSD USB Reader

COM-13004Suggested Reading

If you aren't familiar with the MicroMod ecosystem, we recommend reading here for an overview. We recommend reading here for an overview if you decide to take advantage of the Qwiic connector.

|

|

| MicroMod Ecosystem | Qwiic Connect System |

If you aren’t familiar with the following concepts, we also recommend checking out a few of these tutorials before continuing. Make sure to check the respective hookup guides for your processor board and function board to ensure that you are installing the correct USB-to-serial converter. You may also need to follow additional instructions that are not outlined in this tutorial to install the appropriate software.

What is an Arduino?

Installing Arduino IDE

How to Install CH340 Drivers

Getting Started with MicroMod

Hardware Overview

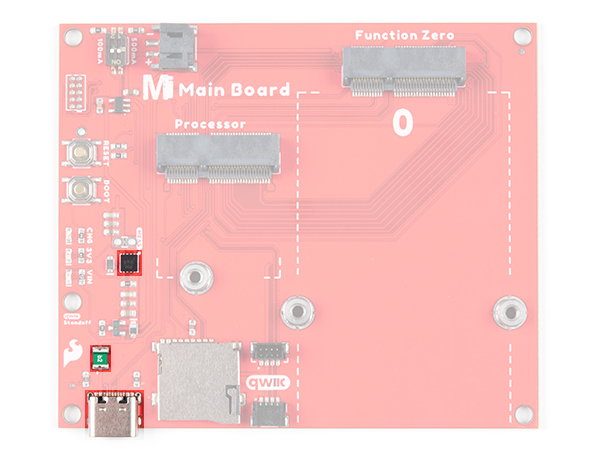

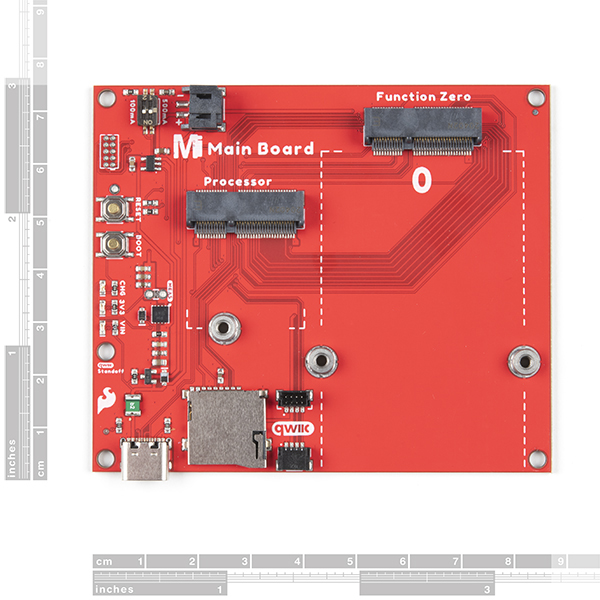

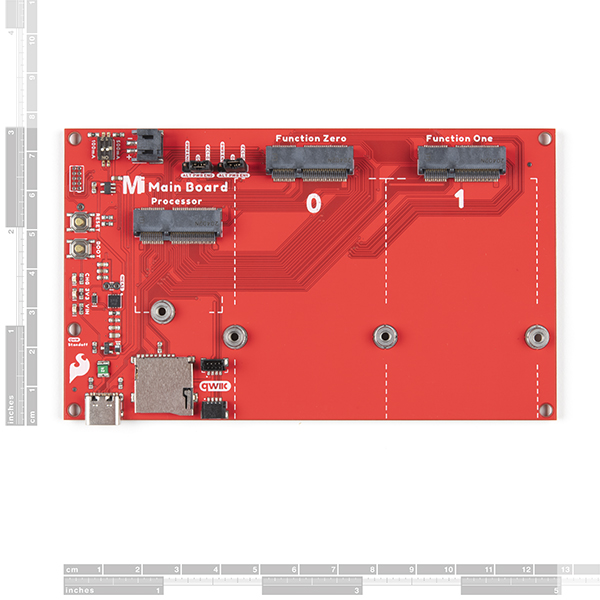

The overall functionality of the Single and Double Main Boards are the same. We'll use the Single Main Board more in this section to highlight the features since this is also included in the Double Main Board. We'll switch to the Double Main Board when necessary to highlight the features that are only included in the Double Main Board.

The only differences are that the Double Main Board includes:

- two jumper shunts

- ability to add a second MicroMod Function Board to the mix

- board's width

|

|

| Main Board - Single Measurements | Main Board - Double Measurements (Zoomed Out) |

Power

There are two ways to power the Main Boards, Processor Board, and Function Board(s).

- USB

- Single Cell LiPo Battery

It is fine to connect a power source to the USB connector and LiPo battery's JST connector at the same time. The MicroMod Main Board has power-control circuitry to automatically select the best power source.

Power USB

One option of powering the board is through the USB Type C connector. You will need a USB Type C cable to power the board with 5V. Power connected to the board's USB C connector will go through a resettable PTC fuse (rated at 2A max) and then the AP7361C 3.3V voltage regulator (rated at 1A max). The little green component close to the USB connector is the resettable PTC fuse while the square IC is the voltage regulator. The voltage regulator accepts voltages between ~3.3V to 6.0V.

The USB Type C connector is also used to upload code to your Processor Board, send serial data to a terminal window, or charge the LiPo battery. Of course for portable power, you could connect a USB battery as an alternative to using a LiPo battery.

Power applied to the connector will light up the VIN and 3V3 LED. If you decide to bypass the PTC fuse, simply add a solder blob to the jumper labeled as PTC. There is also a jumper labeled as MEAS to measure the current consumption at the output of the 3.3V voltage regulator for your project.

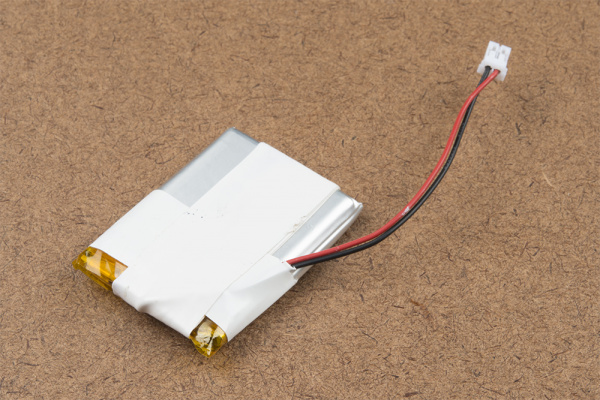

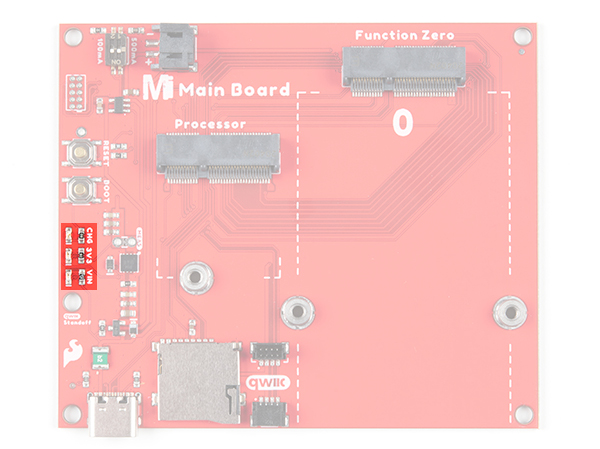

Power LiPo

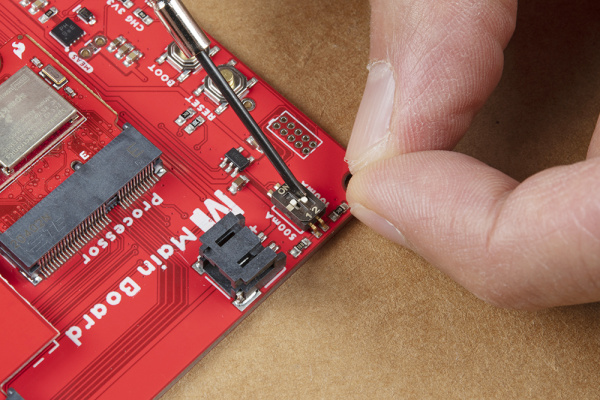

The other option is to connect a single cell LiPo battery (i.e. nominal 3.7V, 4.2V fully charged) to the 2-pin JST connector as shown below. A MCP73831 charge IC is included on the boards to safely charge the LiPo batteries via USB Type C connector. A switch is included to set the charge rate. The charge rate is probably set to ~166mA with both switches flipped to the ON position. This may vary depending on the position of the switch when it was pulled from the reel. Flip the switch to adjust the charge rate to either 100mA or 500mA using a precision flat head screw driver or tweezers.

The voltage from the LiPo battery is regulated down to 3.3V as it goes through the AP7361C 3.3V voltage regulator (rated at 1A max).

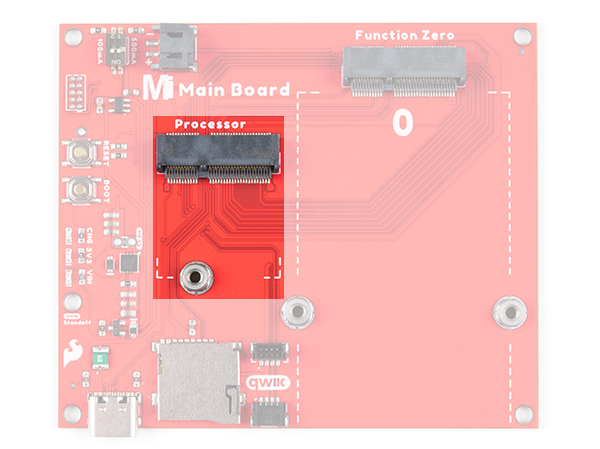

MicroMod Processor Board

The MicroMod ecosystem allows you to easily swap out processors depending on your application. The location of the M.2 connector labeled as Processor is where you would connect and secure a MicroMod Processor Board.

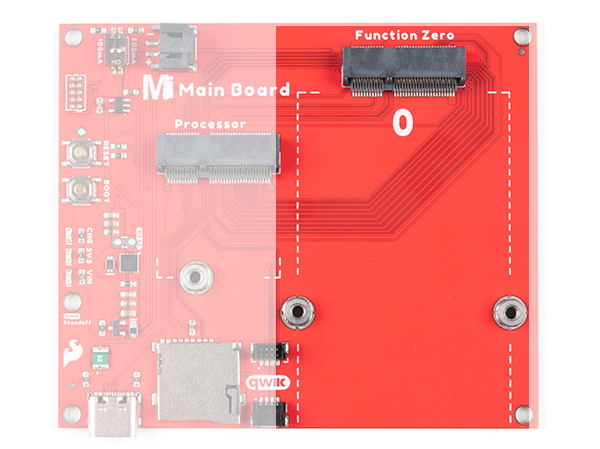

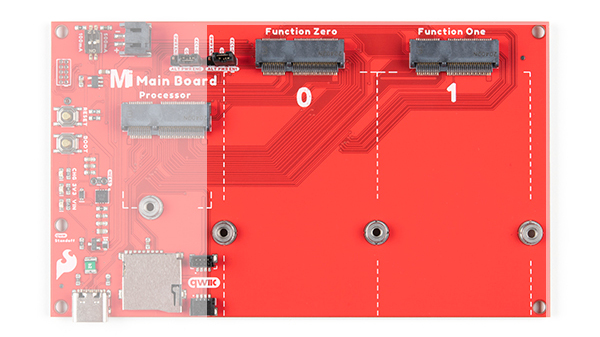

MicroMod Function Board

Beside the MicroMod Processor's socket is another M.2 connector for MicroMod Function Boards, which allow you to add additional functionality to your Processor Board. The Single Main Board includes one socket for a single Function Board while the Double Main Board includes two sockets for up two Function Boards.

|

|

| Main Board - Single Function Board Socket | Main Board - Double Function Board Sockets |

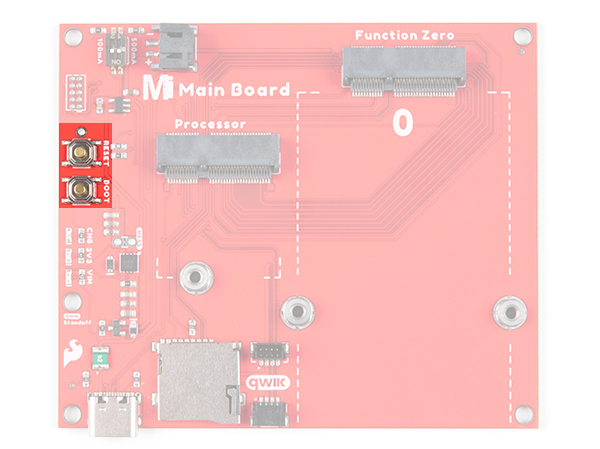

Reset and Boot Buttons

Each board includes a reset and boot button. There is an additional reset button PTH next to the reset button. Hitting the reset button to restart your Processor Board. Hitting the boot button will put the Processor Board into a special boot mode. Depending on the processor board, this boot pin may not be connected.

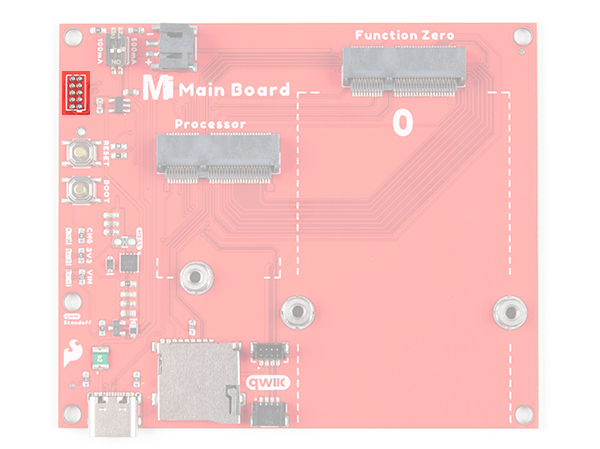

SWD Pins

For advanced users, we broke out the 2x5 SWD programming pins. Note that this is not populated so you will need a compatible header and compatible JTAG programmer to connect.

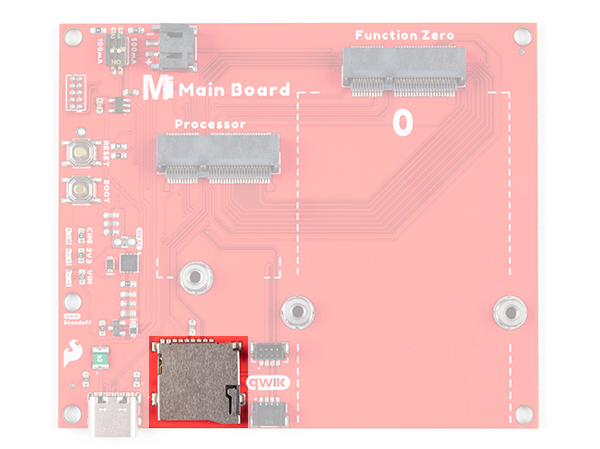

MicroSD Socket

The board includes a microSD socket if your application requires you to log and save data to a memory card. The primary SPI pins (SDO, SDI, SCK, CS0) from your Processor and Function Board are connected to the microSD Socket.

D1 while the MicroMod Main Board - Double is on the Processor Board's G4.

LEDs

There are three LEDs on the board:

- VIN - The VIN LED lights up to indicate when power available from the USB connector.

- 3V3 - The 3V3 LED lights up to indicate when there is a 3.3V available after power is regulated down from the USB connector or LiPo battery.

- CHG - The on-board yellow CHG LED can be used to get an indication of the charge status of your battery. Below is a table of other status indicators depending on the state of the charge IC.

| Charge State | LED status |

| No Battery | Floating (should be OFF, but may flicker) |

| Shutdown | Floating (should be OFF, but may flicker) |

| Charging | ON |

| Charge Complete | OFF |

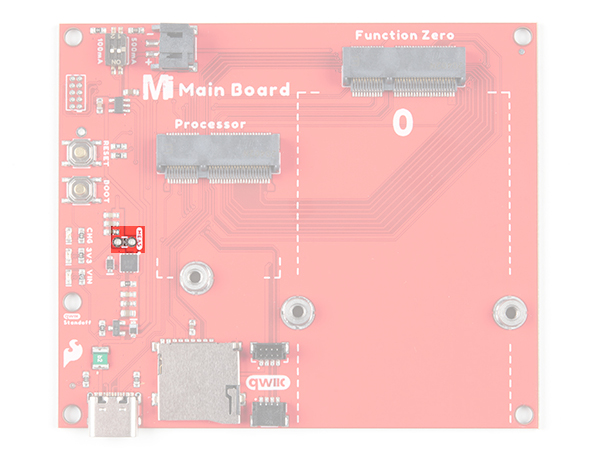

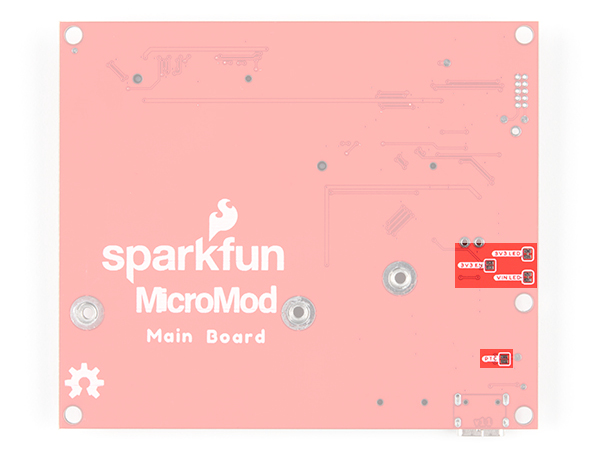

Jumpers

The following five jumpers are included on both the Single and Double Main Boards.

- MEAS - By default, the jumper is closed and located on the top side of the board. This jumper is used to measure your system's current consumption. You can cut this jumper's trace and connect the PTHs to a ammeter/multimeter to probe the output from the 3.3V voltage regulator. Check out our How to Use a Multimeter tutorial for more information on measuring current.

- PTC - By default, the jumper is open and located on the bottom of the board. For advanced users that know what you are doing, add a solder blob to the jumper to bypass the resettable PTC fuse to pull more than 2A from the USB source.

- 3.3V EN - By default, this jumper is open and located on the bottom of the board. Closing this jumper enables processor control of the 3.3V bus.

- VIN LED - By default, this jumper is closed and located on the bottom of the board. Cut this trace to disable the LED that is connected to the input of the USB

- 3.3V LED - By default, this jumper is closed and located on the bottom of the board. Cut this trace to disable the LED that is connected to the output of the 3.3V voltage regulator.

|

|

| Main Board - Single Top View Jumpers |

Main Board - Single Bottom View Jumpers |

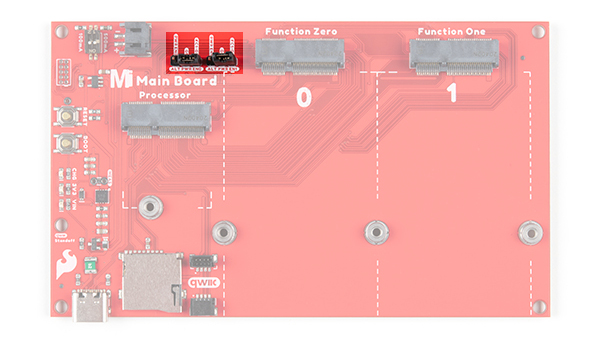

Included only on the Double Main Board are two 1x3 male headers with 2-pin jumper shunts to enable the 3.3V voltage regulator for any Function Board connected to Function Zero and Function One using alternative Processor GPIO pins. Since certain processors have limited GPIO and may not be broken out on certain locations, alternative pins have been provided on the board. The ALT PWR EN0 jumper allows users to control the 3.3V voltage regulator on any Function Board that is connected to Function Zero. When the jumper shunt is on the left side toward the 2-pin JST connector, the jumper shunt connects the PWR EN0 to the Processor Board's GPIO G5 pin. Moving the jumper shunt to the other side connects the Processor Board's GPIO G5 pin to Function Board One's GPIO G3 pin.

The ALT PWR EN1 jumper allows users control power from the 3.3V voltage regulator for any Function Board that is connected to Function One when the jumper shunt is connecting PWR EN1 and Processor Board's GPIO G6 pin. Moving the jumper shunt to the other side connects the Processor Board's GPIO G6 pin to Function Board One's GPIO G4 pin.

Qwiic and I2C

The board includes a vertical and horizontal Qwiic connector. These are connected to the primary I2C bus and 3.3V power on both the Processor and Function Board connectors allowing you to easily add a Qwiic-enabled device to your application.

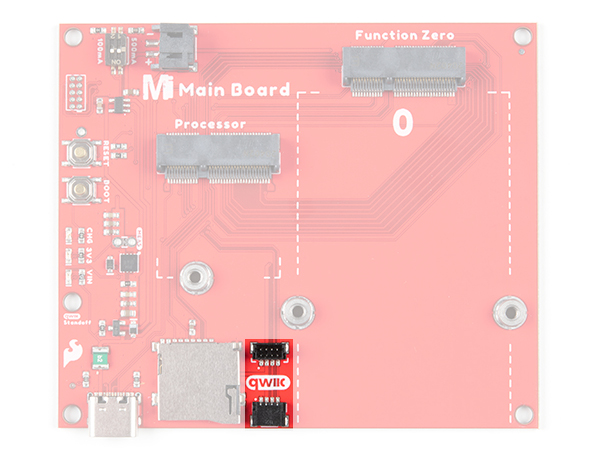

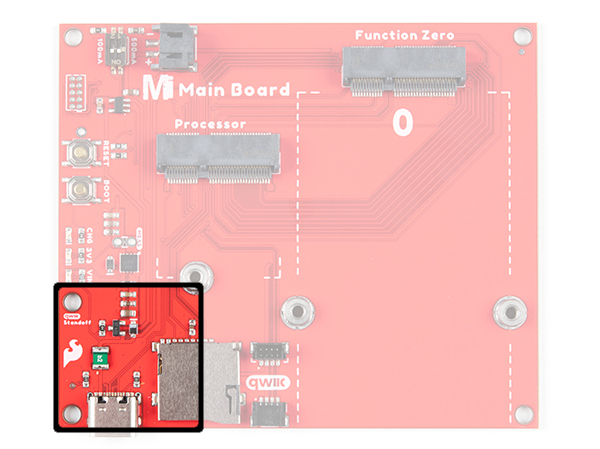

Note that there are two mounting holes for Qwiic-enabled boards that have a standard 1.0"x1.0" size board. The image below highlighted with a black square is where you would place the board.

MicroMod Pinout

Depending on your window size, you may need to use the horizontal scroll bar at the bottom of the table to view the additional pin functions. Note that the M.2 connector pins on opposing sides are offset from each other as indicated by the bottom pins where it says (Not Connected)*. There is no connection to pins that have a "-" under the primary function.

| AUDIO | UART | GPIO/BUS | I2C | SDIO | SPI | Dedicated |

| Processor Pins | Function Zero Pins | Main Board - Single Miscellaneous Pins |

|---|---|---|

| GND | GND | GND |

| 3.3V | - | 3.3V |

| USB_D+_Processor | - | USB_D+ |

| 3.3V_EN | - | 3.3V_EN |

| USB_D-_Processor | - | USB_D- |

| RESET# (I - Open Drain) | - | RESET# (I - Open Drain) |

| GND | GND | GND |

| USB_VIN | - | USB_VIN |

| D0_Processor | F0 | - |

| BOOT (I - Open Drain) | - | BOOT (I - Open Drain) |

| I2C_SDA_Processor | I2C_SDA | I2C_SDA (Qwiic) |

| UART_RTS_Processor | UART_RTS | - |

| I2C_SCL_Processor | I2C_SCL | I2C_SCL (Qwiic) |

| UART_CTS_Processor | UART_CTS | - |

| I2C_INT_Processor | I2C_INT | - |

| UART_TX_Processor | UART_RX | - |

| D1_Processor | - | SD Card CS (microSD Card) |

| UART_RX_Processor | UART_TX | - |

| SWDCK_Processor | - | SWDCK (2x5 Header) |

| SWDIO_Processor | - | SWDCK (2x5 Header) |

| PWM0_Processor | PWM0 | - |

| GND | GND | GND |

| A0_Processor | A0 | - |

| USBHOST_D+_Processor | USBHOST_D+ | - |

| GND | GND | GND |

| USBHOST_D-_Processor | USBHOST_D- | - |

| A1_Processor | PWR_EN0 | - |

| GND | GND | GND |

| G0_Processor | F3 | - |

| CAN_RX_Processor | CAN_TX | - |

| G1_Processor | F4 | - |

| CAN_TX_Processor | CAN_RX | - |

| G2_Processor | F5 | - |

| GND | GND | GND |

| G3_Processor | F6 | - |

| G4_Processor | F7 | - |

| BATT_VIN / 3 (I - ADC) (0 to 3.3V) | - | BATT_VIN / 3 (I - ADC) (0 to 3.3V) |

| SPI_CS0_Processor | F1 | - |

| SPI_SCK_Processor | SPI_SCK | SPI_SCK (microSD Card) |

| SPI_DI_Processor | SPI_DO | SPI_DO (microSD Card) |

| SPI_DO_Processor | SPI_DI | SPI_DI (microSD Card) |

| SDIO_DATA2_Processor | PWR_EN0 | - |

| Processor Pins | Function Zero Pins | Function One Pins | Main Board - Double Miscellaneous Pins |

|---|---|---|---|

| GND | GND | GND | GND |

| 3.3V | - | - | 3.3V |

| USB_D+_Processor | - | - | USB_D+ |

| 3.3V_EN | - | - | 3.3V_EN |

| USB_D-_Processor | - | - | USB_D- |

| RESET# (I - Open Drain) | - | - | RESET# (I - Open Drain) |

| GND | GND | GND | GND |

| - | - | - | - |

| USB_VIN | - | - | USB_VIN |

| D0_Processor | F0 | - | - |

| BOOT (I - Open Drain) | - | - | BOOT (I - Open Drain) |

| I2C_SDA_Processor | I2C_SDA | I2C_SDA | I2C_SDA (Qwiic) |

| UART1_RTS_Processor | UART_RTS | (No Flow Control) | - |

| I2C_SCL_Processor | I2C_SCL | I2C_SCL | I2C_SCL (Qwiic) |

| UART_CTS_Processor | UART_CTS | (No Flow Control) | - |

| I2C_INT_Processor | I2C_INT | I2C_INT | - |

| UART1_TX_Processor | UART_RX | - | - |

| D1_Processor | - | F0 | - |

| UART1_RX_Processor | UART_TX | - | - |

| UART2_RX_Processor | - | UART_TX | - |

| SWDCK_Processor | - | - | SWDCK (2x5 Header) |

| UART2_TX_Processor | - | UART_RX | - |

| SWDIO_Processor | - | - | SWDCK (2x5 Header) |

| PWM0_Processor | PWM | - | - |

| GND | GND | GND | GND |

| A0_Processor | A0 | - | - |

| USBHOST_D+_Processor | USBHOST_D+ | (No USB Host) | - |

| GND | GND | GND | GND |

| USBHOST_D-_Processor | USBHOST_D- | (No USB Host) | - |

| A1_Processor | - | A0 | - |

| GND | GND | GND | GND |

| G0_Processor | F3 | - | - |

| CAN_RX_Processor | CAN_TX | (No CAN BUS) | - |

| G1_Processor | F4 | - | - |

| CAN_TX_Processor | CAN_RX | (No CAN BUS) | - |

| G2_Processor | F5 | - | - |

| GND | GND | GND | GND |

| G3_Processor | F6 | - | - |

| PWM1_Processor | - | PWM | - |

| G4_Processor | F7 | - | SD Card CS (microSD Card) |

| BATT_VIN / 3 (I - ADC) (0 to 3.3V) | - | - | BATT_VIN / 3 (I - ADC) (0 to 3.3V) |

| - | - | - | - |

| - | - | - | - |

| - | - | - | - |

| - | - | - | - |

| - | - | - | - |

| SPI_CS0_Processor | F1 | - | - |

| - | - | - | - |

| SPI_SCK_Processor | SPI_SCK | SPI_SCK | SPI_SCK (microSD Card) |

| - | - | - | - |

| SPI_DI_Processor | SPI_DO | SPI_DO | SPI_DO (microSD Card) |

| SDIO_CLK_Processor | - | F7 | - |

| SPI_DO_Processor | SPI_DI | SPI_DI | SPI_DI (microSD Card) |

| SDIO_CMD_Processor | - | F6 | - |

| - | - | - | - |

| - | - | - | - |

| - | - | - | - |

| SDIO_DATA1_Processor | - | PWR_EN1 | - |

| - | - | - | - |

| SDIO_DATA2_Processor | PWR_EN0 | - | - |

| G7_Processor | - | F5 | - |

| SPI_CS1_Processor | - | SPI_CS1 | - |

| G6_Processor | - | F4 | - |

| - | - | - | - |

| Alternative Function |

Primary Function |

Bottom Pin |

Top Pin |

Primary Function |

Alternative Function |

|---|---|---|---|---|---|

| (Not Connected) | 75 | GND | |||

| VIN | 74 | 73 | 3.3V | ||

| VIN | 72 | 71 | Power EN | ||

| - | 70 | 69 | - | ||

| - | 66 | 65 | - | ||

| - | 64 | 63 | - | ||

| - | 62 | 61 | F7 | ||

| - | 60 | 59 | F6 | ||

| - | 58 | 57 | F5 | ||

| - | 56 | 55 | F4 | ||

| - | 54 | 53 | F3 | ||

| - | 52 | 51 | F2 | PWM | |

| - | 50 | 49 | F1 | SPI_CS0 | |

| - | 48 | 47 | F0 | INT | |

| - | 46 | 45 | GND | ||

| - | 44 | 43 | CAN_TX | ||

| - | 42 | 41 | CAN_RX | ||

| - | 40 | 39 | GND | ||

| A0 | 38 | 37 | USBHOST_D- | ||

| EEPROM_A0 | 36 | 35 | USBHOST_D+ | ||

| EEPROM_A1 | 34 | 33 | GND | ||

| EEPROM_A2 | 32 | 31 | Module Key | ||

| Module Key | 30 | 29 | Module Key | ||

| Module Key | 28 | 27 | Module Key | ||

| Module Key | 26 | 25 | Module Key | ||

| Module Key | 24 | 23 | I2C_INT | ||

| - | 22 | 21 | I2C_SCL | ||

| - | 20 | 19 | I2C_SDA | ||

| UART_CTS | 18 | 17 | - | ||

| UART_RTS | 16 | 15 | UART_RX | ||

| - | 14 | 13 | UART_TX | ||

| - | 12 | 11 | - | ||

| - | 10 | 9 | - | ||

| - | 8 | 7 | SPI_SDO | ||

| - | 6 | 5 | SPI_SDI | ||

| - | 4 | 3 | SPI_SCK | ||

| - | 2 | 1 | GND |

| Alternative Function | Alternative Function | Alternative Function | Primary Function | Bottom Pin |

Top Pin |

Primary Function | Alternative Function | Alternative Function | Alternative Function |

|---|---|---|---|---|---|---|---|---|---|

| (Not Connected) | 75 | GND | |||||||

| 3.3V | 74 | 73 | G5 / BUS5 | ||||||

| RTC_3V_BATT | 72 | 71 | G6 / BUS6 | ||||||

| SPI_CS1# | SDIO_DATA3 (I/O) | 70 | 69 | G7 / BUS7 | |||||

| SDIO_DATA2 (I/O) | 68 | 67 | G8 | ||||||

| SDIO_DATA1 (I/O) | 66 | 65 | G9 | ADC_D- | CAM_HSYNC | ||||

| SPI_CIPO1 | SDIO_DATA0 (I/O) | 64 | 63 | G10 | ADC_D+ | CAM_VSYNC | |||

| SPI COPI1 | SDIO_CMD (I/O) | 62 | 61 | SPI_CIPO (I) | |||||

| SPI SCK1 | SDIO_SCK (O) | 60 | 59 | SPI_COPI (O) | LED_DAT | ||||

| AUD_MCLK (O) | 58 | 57 | SPI_SCK (O) | LED_CLK | |||||

| CAM_MCLK | PCM_OUT | I2S_OUT | AUD_OUT | 56 | 55 | SPI_CS# | |||

| CAM_PCLK | PCM_IN | I2S_IN | AUD_IN | 54 | 53 | I2C_SCL1 (I/O) | |||

| PDM_DATA | PCM_SYNC | I2S_WS | AUD_LRCLK | 52 | 51 | I2C_SDA1 (I/O) | |||

| PDM_CLK | PCM_CLK | I2S_SCK | AUD_BCLK | 50 | 49 | BATT_VIN / 3 (I - ADC) (0 to 3.3V) | |||

| G4 / BUS4 | 48 | 47 | PWM1 | ||||||

| G3 / BUS3 | 46 | 45 | GND | ||||||

| G2 / BUS2 | 44 | 43 | CAN_TX | ||||||

| G1 / BUS1 | 42 | 41 | CAN_RX | ||||||

| G0 / BUS0 | 40 | 39 | GND | ||||||

| A1 | 38 | 37 | USBHOST_D- | ||||||

| GND | 36 | 35 | USBHOST_D+ | ||||||

| A0 | 34 | 33 | GND | ||||||

| PWM0 | 32 | 31 | Module Key | ||||||

| Module Key | 30 | 29 | Module Key | ||||||

| Module Key | 28 | 27 | Module Key | ||||||

| Module Key | 26 | 25 | Module Key | ||||||

| Module Key | 24 | 23 | SWDIO | ||||||

| UART_TX2 (O) | 22 | 21 | SWDCK | ||||||

| UART_RX2 (I) | 20 | 19 | UART_RX1 (I) | ||||||

| CAM_TRIG | D1 | 18 | 17 | UART_TX1 (0) | |||||

| I2C_INT# | 16 | 15 | UART_CTS1 (I) | ||||||

| I2C_SCL (I/0) | 14 | 13 | UART_RTS1 (O) | ||||||

| I2C_SDA (I/0) | 12 | 11 | BOOT (I - Open Drain) | ||||||

| D0 | 10 | 9 | USB_VIN | ||||||

| SWO | G11 | 8 | 7 | GND | |||||

| RESET# (I - Open Drain) | 6 | 5 | USB_D- | ||||||

| 3.3V_EN | 4 | 3 | USB_D+ | ||||||

| 3.3V | 2 | 1 | GND |

| Signal Group | Signal | I/O | Description | Voltage | Power | 3.3V | I | 3.3V Source | 3.3V |

|---|---|---|---|---|

| GND | Return current path | 0V | ||

| USB_VIN | I | USB VIN compliant to USB 2.0 specification. Connect to pins on processor board that require 5V for USB functionality | 4.8-5.2V | |

| RTC_3V_BATT | I | 3V provided by external coin cell or mini battery. Max draw=100μA. Connect to pins maintaining an RTC during power loss. Can be left NC. | 3V | |

| 3.3V_EN | O | Controls the carrier board's main voltage regulator. Voltage above 1V will enable 3.3V power path. | 3.3V | |

| BATT_VIN/3 | I | Carrier board raw voltage over 3. 1/3 resistor divider is implemented on carrier board. Amplify the analog signal as needed for full 0-3.3V range | 3.3V | |

| Reset | Reset | I | Input to processor. Open drain with pullup on processor board. Pulling low resets processor. | 3.3V |

| Boot | I | Input to processor. Open drain with pullup on processor board. Pulling low puts processor into special boot mode. Can be left NC. | 3.3V | |

| USB | USB_D± | I/O | USB Data ±. Differential serial data interface compliant to USB 2.0 specification. If UART is required for programming, USB± must be routed to a USB-to-serial conversion IC on the processor board. | |

| USB Host | USBHOST_D± | I/O | For processors that support USB Host Mode. USB Data±. Differential serial data interface compliant to USB 2.0 specification. Can be left NC. | |

| CAN | CAN_RX | I | CAN Bus receive data. | 3.3V |

| CAN_TX | O | CAN Bus transmit data. | 3.3V | |

| UART | UART_RX1 | I | UART receive data. | 3.3V |

| UART_TX1 | O | UART transmit data. | 3.3V | |

| UART_RTS1 | O | UART ready to send. | 3.3V | |

| UART_CTS1 | I | UART clear to send. | 3.3V | |

| UART_RX2 | I | 2nd UART receive data. | 3.3V | |

| UART_TX2 | O | 2nd UART transmit data. | 3.3V | |

| I2C | I2C_SCL | I/O | I2C clock. Open drain with pullup on carrier board. | 3.3V |

| I2C_SDA | I/O | I2C data. Open drain with pullup on carrier board | 3.3V | |

| I2C_INT# | I | Interrupt notification from carrier board to processor. Open drain with pullup on carrier board. Active LOW | 3.3V | |

| I2C_SCL1 | I/O | 2nd I2C clock. Open drain with pullup on carrier board. | 3.3V | |

| I2C_SDA1 | I/O | 2nd I2C data. Open drain with pullup on carrier board. | 3.3V | |

| SPI | SPI_COPI | O | SPI Controller Output/Peripheral Input. | 3.3V |

| SPI_CIPO | I | SPI Controller Input/Peripheral Output. | 3.3V | |

| SPI_SCK | O | SPI Clock. | 3.3V | |

| SPI_CS# | O | SPI Chip Select. Active LOW. Can be routed to GPIO if hardware CS is unused. | 3.3V | |

| SPI/SDIO | SPI_SCK1/SDIO_CLK | O | 2nd SPI Clock. Secondary use is SDIO Clock. | 3.3V |

| SPI_COPI1/SDIO_CMD | I/O | 2nd SPI Controller Output/Peripheral Input. Secondary use is SDIO command interface. | 3.3V | |

| SPI_CIPO1/SDIO_DATA0 | I/O | 2nd SPI Peripheral Input/Controller Output. Secondary use is SDIO data exchange bit 0. | 3.3V | |

| SDIO_DATA1 | I/O | SDIO data exchange bit 1. | 3.3V | |

| SDIO_DATA2 | I/O | SDIO data exchange bit 2. | 3.3V | |

| SPI_CS1/SDIO_DATA3 | I/O | 2nd SPI Chip Select. Secondary use is SDIO data exchange bit 3. | 3.3V | |

| Audio | AUD_MCLK | O | Audio master clock. | 3.3V |

| AUD_OUT/PCM_OUT/I2S_OUT/CAM_MCLK | O | Audio data output. PCM synchronous data output. I2S serial data out. Camera master clock. | 3.3V | |

| AUD_IN/PCM_IN/I2S_IN/CAM_PCLK | I | Audio data input. PCM syncrhonous data input. I2S serial data in. Camera periphperal clock. | 3.3V | |

| AUD_LRCLK/PCM_SYNC/I2S_WS/PDM_DATA | I/O | Audio left/right clock. PCM syncrhonous data SYNC. I2S word select. PDM data. | 3.3V | |

| AUD_BCLK/PCM_CLK/I2S_CLK/PDM_CLK | O | Audio bit clock. PCM clock. I2S continuous serial clock. PDM clock. | 3.3V | |

| SWD | SWDIO | I/O | Serial Wire Debug I/O. Connect if processor board supports SWD. Can be left NC. | 3.3V |

| SWDCK | I | Serial Wire Debug clock. Connect if processor board supports SWD. Can be left NC. | 3.3V | |

| ADC | A0 | I | Analog to digital converter 0. Amplify the analog signal as needed to enable full 0-3.3V range. | 3.3V |

| A1 | I | Analog to digital converter 1. Amplify the analog signal as needed to enable full 0-3.3V range. | 3.3V | |

| PWM | PWM0 | O | Pulse width modulated output 0. | 3.3V |

| PWM1 | O | Pulse width modulated output 1. | 3.3V | |

| Digital | D0 | I/O | General digital input/output pin. | 3.3V |

| D1/CAM_TRIG | I/O | General digital input/output pin. Camera trigger. | 3.3V | |

| General/Bus | G0/BUS0 | I/O | General purpose pins. Any unused processor pins should be assigned to Gx with ADC + PWM capable pins given priority (0, 1, 2, etc.) positions. The intent is to guarantee PWM, ADC and Digital Pin functionality on respective ADC/PWM/Digital pins. Gx pins do not guarantee ADC/PWM function. Alternative use is pins can support a fast read/write 8-bit or 4-bit wide bus. | 3.3V |

| G1/BUS1 | I/O | 3.3V | ||

| G2/BUS2 | I/O | 3.3V | ||

| G3/BUS3 | I/O | 3.3V | ||

| G4/BUS4 | I/O | 3.3V | ||

| G5/BUS5 | I/O | 3.3V | ||

| G6/BUS6 | I/O | 3.3V | ||

| G7/BUS7 | I/O | 3.3V | ||

| G8 | I/O | General purpose pin | 3.3V | |

| G9/ADC_D-/CAM_HSYNC | I/O | Differential ADC input if available. Camera horizontal sync. | 3.3V | |

| G10/ADC_D+/CAM_VSYNC | I/O | Differential ADC input if available. Camera vertical sync. | 3.3V | |

| G11/SWO | I/O | General purpose pin. Serial Wire Output | 3.3V |

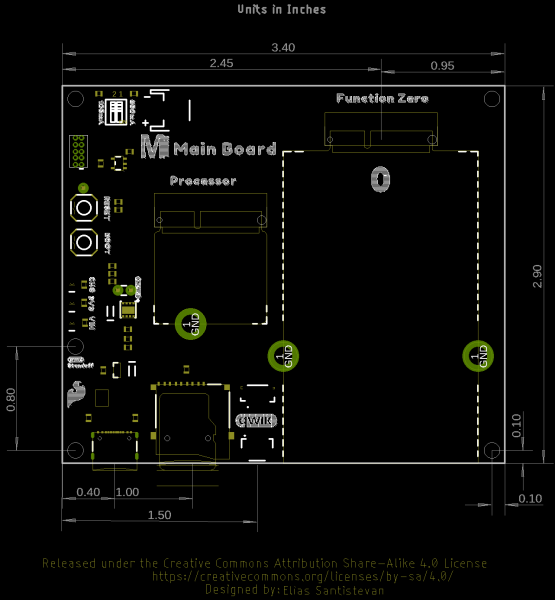

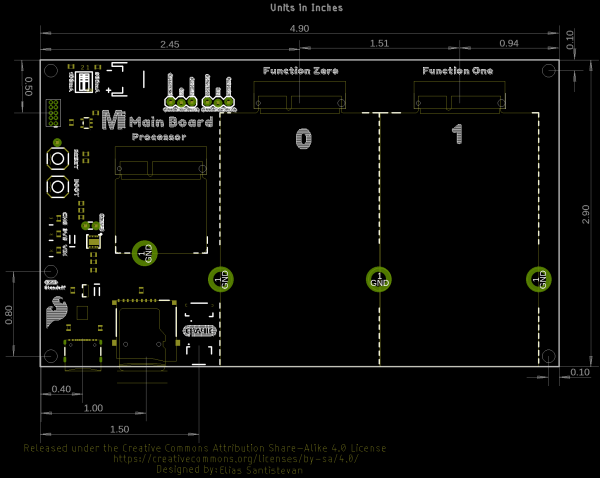

Board Dimensions

The board dimension of the MicroMod Main Board - Single is 2.90" x 3.40" while the MicroMod Main Board - Double is 2.90" x 4.90". Both boards include 5x mounting holes. Four are located on the edge of each board. The fifth mounting hole is located 0.80" away from another mounting hole to mount Qwiic-enabled boards that have the standard 1.0"x1.0" size board.

|

|

| MicroMod Main Board - Single | MicroMod Main Board - Double |

Hardware Hookup

If you have not already, make sure to check out the Getting Started with MicroMod: Hardware Hookup for information on inserting your Processor and Function Boards to the Main Board.

Getting Started with MicroMod

USB

To program and power the Main Board, you will need to insert the USB-C cable into the USB connector. We will leave the other end disconnected when connecting a Processor or Function board to the Main Board.

When the boards are secure, insert the other end to a computer. When you are finished programming the processor, you can use a USB battery via the USB connector or LiPo battery via the JST connector to power the board.

Processor Board

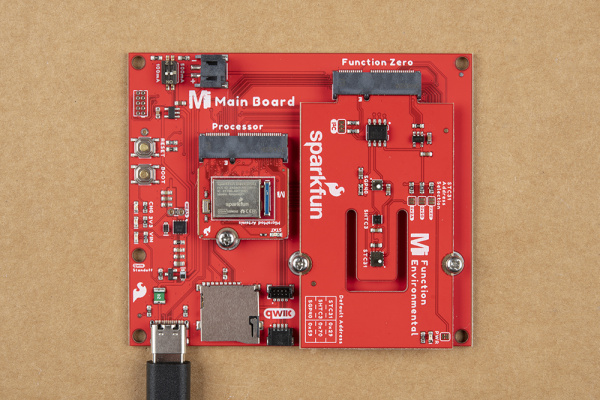

Align the Processor Board's key into its M.2 connector's socket. Insert the board at an angle (~25°), push down, and tighten the screw. In this case, we had the MicroMod Artemis Processor Board secured in the M.2 connector socket. Depending on your application, you may have a different Processor Board.

Function Boards

Align the Function Board's key into its M.2 connector's socket. Insert the board at an angle (~25°), push down, and tighten one of the screw to hold the board down. Attach the second screw on the other side of the board. Once the board is aligned, tighten both screws fully to secure the board. In this case, we had the Environmental Function Board secured in the M.2 connector socket. Depending on your application, you may have a different Function Board.

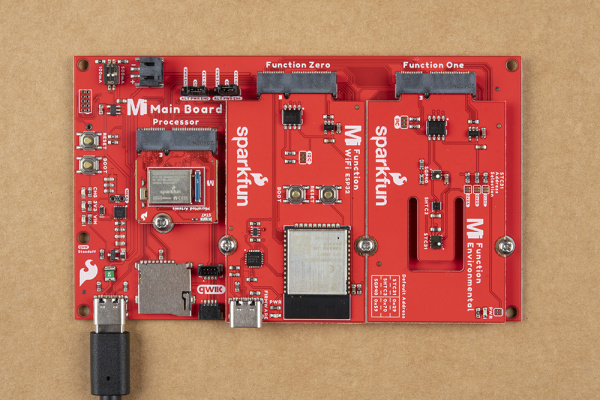

If you decide to have two function boards attached to the Main Board - Double, we recommend tightening the screw between the two Function Boards first to hold them down before attaching the remaining screws on either side of the Function Boards. In this case, we had the WiFi Function Board and the Environmental Function Board secured in the M.2 connector socket. Depending on your application, you may have different function boards.

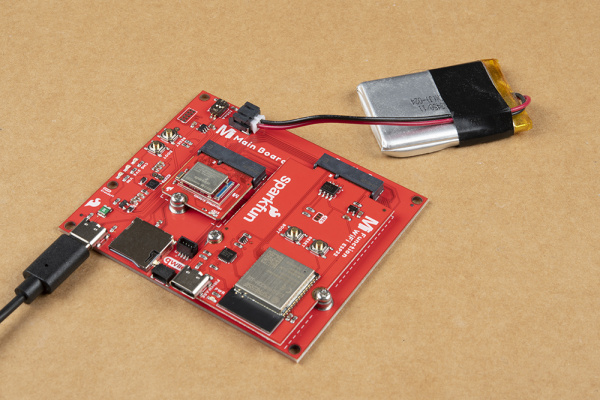

Single Cell LiPo Battery

A precision flat head (or a tiny, rounded object) is needed to set the charge rate for your single cell LiPo battery. When the switch is flipped to the ON position on the 500mA side, the charge rate will be 500mA. When the switch is flipped to the ON position on the 100mA side, the charge rate will be 100mA. When the switch is flipped to the ON position on both the 100mA and 500mA sides, the charge rate will be 166mA.

For mobile applications, attach a single cell LiPo battery to the 2-pin JST connector. Attach a USB cable to a USB port or charger when the battery is low to begin charging.

To remove the LiPo battery, you can pull the white JST connector away from the socket while also wiggling the connector side to side using your thumb and index finger.

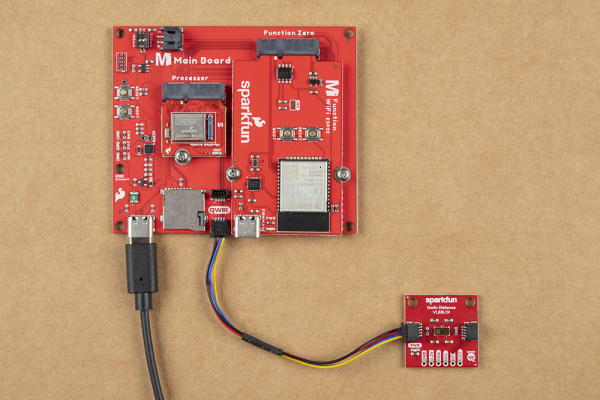

Qwiic-Enabled Devices

To Qwiic-ly connect I2C devices, simply insert a Qwiic cable between one of the MicroMod Main Board's Qwiic ports and your Qwiic device.

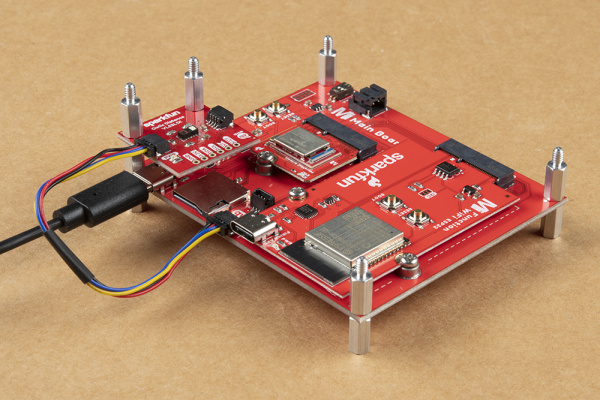

If you need to mount a Qwiic-enabled board to the MicroMod Main Board, you can grab some standoffs and mount a standard Qwiic 1.0"x1.0" sized board using the two mounting holes near the USB Type C connector. Place the standoff between the boards and tighten the screws to mount. The image below used standoffs with built-in threads.

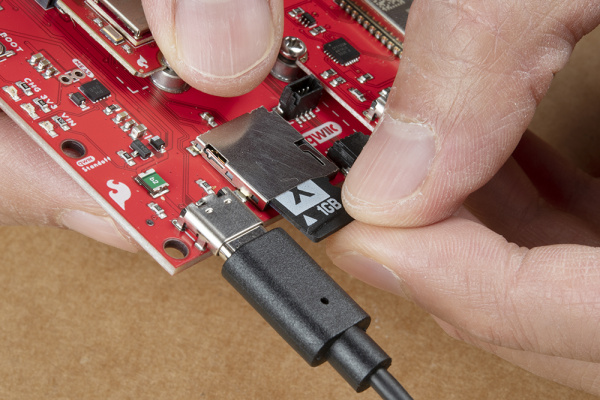

MicroSD Card

With power removed from the board, insert a microSD card (with the pins facing toward the board) into the socket. You'll hear a nice click indicating that the microSD card is locked in place.

To remove, make sure power is off and press the microSD card into the socket to eject. You'll hear a nice click indicating that the card is ready to be removed from the socket.

Software Installation

Arduino Board Definitions and Driver

We'll assume that you installed the necessary board files and drivers for your Processor Board. In this case, we used the MicroMod Artemis Processor Board which uses the CH340 USB-to-serial converter. If you are using a Processor Board, make sure to check out its hookup guide for your Processor Board.

Installing Board Definitions in the Arduino IDE

MicroMod Artemis Processor Board Hookup Guide

How to Install CH340 Drivers

Arduino Examples

Let's go over a few basic examples to get started with the MicroMod Main Board Single and Double. We'll toggle the 3.3V voltage regulator and log data to a microSD card on both boards.

Example 1: MicroMod Main Board - Single Enable Function Board

If you have not already, select your Board (in this case the MicroMod Artemis), and associated COM port. Copy and paste the code below in your Arduino IDE. Hit the upload button and set the serial monitor to 115200 baud.

language:c

/******************************************************************************

WRITTEN BY: Ho Yun "Bobby" Chan

@ SparkFun Electronics

DATE: 10/19/2021

GITHUB REPO: https://github.com/sparkfun/SparkFun_MicroMod_Main_Board_Single

DEVELOPMENT ENVIRONMENT SPECIFICS:

Firmware developed using Arduino IDE v1.8.12

========== DESCRIPTION==========

This example code toggles the Function Board's AP2112 3.3V voltage

regulator's enable pin. The Function Boards built-in power LED should blink.

This example is based on Arduino's built-in Blink Example:

https://www.arduino.cc/en/Tutorial/BuiltInExamples/Blink

Note that this example code uses the MicroMod Main Board - Single. The MicroMod

Main Board - Double routes the PWR_EN# pins slightly different for the

two function boards.

========== HARDWARE CONNECTIONS ==========

MicroMod Artemis Processor Board => MicroMod Main Board - Single => Function Board

Feel like supporting open source hardware?

Buy a board from SparkFun!

MicroMod Artemis Processor Board - https://www.sparkfun.com/products/16401

MicroMod Main Board - Single - https://www.sparkfun.com/products/18575

MicroMod Environmental Function Board - https://www.sparkfun.com/products/18632

LICENSE: This code is released under the MIT License (http://opensource.org/licenses/MIT)

******************************************************************************/

/*Define the power enable pins for the processor board with either SDIO_DATA2 or A1.

Depending on the processor board, the Arduino pin may be different.

Note: Certain Processor Boards like the Artemis have SDIO_Data2 and A1 available

to control the Function Board's voltage regulator. SAMD51, ESP32, and STM32

Processor Board pins do not have SDIO Data 2, so users will need to reference

the Processor Pin A1. Below are a few examples. */

//ARTEMIS

#define PWR_EN0 4 //Function Board 0's "PWR_EN0" pin <= MicroMod SDIO_DATA2 => Artemis Processor Board (D4)

//Alternative option that does the same thing. Make sure to just choose one for PWR_EN0

//#define PWR_EN0 35 //Function Board 0's "PWR_EN0" pin <= MicroMod A1 => Artemis Processor Board (A35)

//TEENSY

//#define PWR_EN0 15 //Function Board 0's "PWR_EN0" pin <= MicroMod A1 => Teensy Processor Board (A1)

//SAMD51

//#define PWR_EN0 18 //Function Board 0's "PWR_EN0" pin <= MicroMod A1 => SAMD51 Processor Board (18)

void setup() {

// initialize the digital pin as an output.

pinMode(PWR_EN0, OUTPUT);

}

void loop() {

digitalWrite(PWR_EN0, HIGH); // turn the 3.3V regulator on (HIGH is the voltage level)

delay(5000); // wait for a few seconds to do something with the function boards

digitalWrite(PWR_EN0, LOW); // turn the 3.3V regulator off by making the voltage LOW

delay(5000); // wait for a few seconds before turning function boards back on

}

After uploading, take a look at your Function Board's PWR LED. The LED will be on for about 5 seconds and then turn off for another 5 seconds. It will continue to repeat until power is removed from the MicroMod Main Board - Single.

Example 2: MicroMod Main Board - Double Enable Function Boards

If you have not already, select your Board (in this case the MicroMod Artemis), and associated COM port. Copy and paste the code below in your Arduino IDE. Hit the upload button and set the serial monitor to 115200 baud.

language:c

/******************************************************************************

WRITTEN BY: Ho Yun "Bobby" Chan

@ SparkFun Electronics

DATE: 10/19/2021

GITHUB REPO: https://github.com/sparkfun/SparkFun_MicroMod_Main_Board_Double

DEVELOPMENT ENVIRONMENT SPECIFICS:

Firmware developed using Arduino IDE v1.8.12

========== DESCRIPTION==========

This example code toggles the Function Board's AP2112 3.3V voltage

regulator's enable pin. The Function Boards built-in power LED should blink.

This example is based on Arduino's built-in Blink Example:

https://www.arduino.cc/en/Tutorial/BuiltInExamples/Blink

Note that this example code uses the MicroMod Main Board - Double. The MicroMod

Main Board - Single routes the PWR_EN0 pin slightly different for the

function board.

========== HARDWARE CONNECTIONS ==========

MicroMod Artemis Processor Board => MicroMod Main Board - Double => Function Boards

Feel like supporting open source hardware?

Buy a board from SparkFun!

MicroMod Artemis Processor Board - https://www.sparkfun.com/products/16401

MicroMod Main Board - Double - https://www.sparkfun.com/products/18576

MicroMod Environmental Function Board - https://www.sparkfun.com/products/18632

LICENSE: This code is released under the MIT License (http://opensource.org/licenses/MIT)

******************************************************************************/

/*Define the power enable pins for the processor board with SDIO_DATA2.

Depending on the processor board, the Arduino pin may be different.

Note: Certain Processor Boards like the Artemis have more than one pin available

to control the Function Board's voltage regulator (e.g. SDIO_DATA2 and G5).

SAMD51, ESP32, and STM32 Processor Board pins do not have SDIO Data 2, so

users will need to reference the Processor Pin G5. Below are a few examples. */

//ARTEMIS

#define PWR_EN0 4 //Function Board 0's "PWR_EN0" pin <= MicroMod SDIO_DATA2 => Artemis Processor Board (D4)

#define PWR_EN1 26 //Function Board 1's "PWR_EN1" pin <= MicroMod SDIO_DATA1 => Artemis Processor Board (D26)

//Alternative option that does the same thing. Make sure to just choose one for PWR_EN0 and PWR_EN1

//#define PWR_EN0 29 //Function Board 0's "PWR_EN0" pin <= MicroMod G5 => Artemis Processor Board (A29)

//#define PWR_EN1 14 //Function Board 1's "PWR_EN0" pin <= MicroMod G6 => Artemis Processor Board (D14)

//TEENSY

//#define PWR_EN0 39 //Function Board 0's "PWR_EN0" pin <= MicroMod SDIO_DATA2 => Teensy Processor Board (D39)

//#define PWR_EN1 34 //Function Board 1's "PWR_EN1" pin <= MicroMod SDIO_DATA1 => Teensy Processor Board (D34)

//Alternative option that does the same thing. Make sure to just choose one for PWR_EN0 and PWR_EN1

//#define PWR_EN0 45 //Function Board 0's "PWR_EN0" pin <= MicroMod G5 => Teensy Processor Board (45)

//#define PWR_EN1 6 //Function Board 1's "PWR_EN1" pin <= MicroMod G6 => Teensy Processor Board (6)

//Note: The SAMD51, ESP32, and STM32 Processor Board Pins do not have SDIO Data 2 and SDIO Data 1.

//SAMD51

//#define PWR_EN0 7 //Function Board 0's "PWR_EN0" pin <= MicroMod G5 => SAMD51 Processor Board (D7)

//#define PWR_EN1 8 //Function Board 1's"PWR_EN1" pin <= MicroMod G6 => SAMD51 Processor Board (D8)

//ESP32

//#define PWR_EN0 32 //Function Board 0's "PWR_EN0" pin <= MicroMod G5 => ESP32 Processor Board (32)

//#define PWR_EN1 33 //Function Board 1's"PWR_EN1" pin <= MicroMod G6 => ESP32 Processor Board (33)

void setup() {

// initialize the digital pins as an output.

pinMode(PWR_EN0, OUTPUT);

pinMode(PWR_EN1, OUTPUT);

}

void loop() {

digitalWrite(PWR_EN0, HIGH); // turn the 3.3V regulator on (HIGH is the voltage level)

digitalWrite(PWR_EN1, HIGH); // turn the 3.3V regulator on (HIGH is the voltage level)

delay(5000); // wait for a few seconds to do something with the function boards

digitalWrite(PWR_EN0, LOW); // turn the 3.3V regulator off by making the voltage LOW

digitalWrite(PWR_EN1, LOW); // turn the 3.3V regulator off by making the voltage LOW

delay(5000); // wait for a few seconds before turning function boards back on

}

After uploading, take a look at the PWR LEDs on the Function Boards. The LEDs will be on for about 5 seconds and then turn off for another 5 seconds. It will continue to repeat until power is removed from the MicroMod Main Board - Double.

Example 3: Reading and Writing to a MicroSD Card

#define SD_CS_PIN SS//TEENSY

#define SD_CS_PIN 5 // The microSD Card CS pin is D1 for the MicroMod Main Board - Single and Teensy Processor (5). Adjust for your processor if necessary.

//#define SD_CS_PIN 44 // The microSD Card's CS pin is G4 for the MicroMod Main Board - Double and Teensy Processor (44). Adjust for your processor if necessary.The example below uses the built-in SD Arduino library. The only difference in the code is the CS pin for the microSD card, which you will need to adjust for your processor board (in this case we use the Artemis Processor Board). Make sure to reference your Processor Board's CS pin for either the Main Board - Single (D1) or Main Board - Double (G4).

If you have not already, select your Board (in this case the MicroMod Artemis), and associated COM port. Copy and paste the code below in your Arduino IDE. Hit the upload button and set the serial monitor to 9600 baud.

language:c

/*

SD Card Read/Write

This example shows how to read and write data to and from an SD card file

The circuit:

SD card attached to SPI bus as follows:

SD Card - MicroMod Artemis Processor Board

-----------------------------------

COPI/SDO - pin 38

CIPO/SDI - pin 43

CLK - pin 42

CS - pin 1 (Main Board - Single) or 28 (Main Board - Double)

created Nov 2010

by David A. Mellis

modified 9 Apr 2012

by Tom Igoe

This example code is in the public domain.

*/

#include <SPI.h>

#include <SD.h>

//ARTEMIS

//const int SD_CS_PIN = 1; // The microSD Card CS pin is D1 for the MicroMod Main Board - Single and Artemis Processor (D1). Adjust for your processor if necessary.

const int SD_CS_PIN = 28; // The microSD Card's CS pin is G4 for the MicroMod Main Board - Double and Artemis Processor (D28). Adjust for your processor if necessary.

File myFile;

void setup() {

// Open serial communications and wait for port to open:

Serial.begin(9600);

while (!Serial) {

; // wait for serial port to connect. Needed for native USB port only

}

Serial.print("Initializing SD card...");

if (!SD.begin(SD_CS_PIN)) {

Serial.println("initialization failed!");

while (1);

}

Serial.println("initialization done.");

// open the file. note that only one file can be open at a time,

// so you have to close this one before opening another.

myFile = SD.open("test.txt", FILE_WRITE);

// if the file opened okay, write to it:

if (myFile) {

Serial.print("Writing to test.txt...");

myFile.println("testing 1, 2, 3.");

// close the file:

myFile.close();

Serial.println("done.");

} else {

// if the file didn't open, print an error:

Serial.println("error opening test.txt");

}

// re-open the file for reading:

myFile = SD.open("test.txt");

if (myFile) {

Serial.println("test.txt:");

// read from the file until there's nothing else in it:

while (myFile.available()) {

Serial.write(myFile.read());

}

// close the file:

myFile.close();

} else {

// if the file didn't open, print an error:

Serial.println("error opening test.txt");

}

}

void loop() {

// nothing happens after setup

}

If all goes well, you should see the following output if this is the first time writing to the card!

language:bash

Initializing SD card...initialization done.

Writing to test.txt...done.

test.txt:

testing 1, 2, 3.

If you are looking to go the extra mile to see if data was saved, close the Serial Monitor and remove power from the MicroMod Main Board. Eject your microSD card from the socket and insert into a microSD card adapter. Then insert the microSD card into your computer's card reader or USB port. Open the test.txt file in a text editor. You should see an output similar to what you saw in the Serial Monitor after the file was opened as shown below.

language:bash

testing 1, 2, 3.

Besides verifying the data in the file, this step is also useful if you adjust the code to continuously log data in a CSV format. After logging data, you could the open text document in a spreadsheet and graph the values!

More Examples!

Sweet! Now that we know that we can read and write to the microSD card, try exploring the other examples in either the SD or SdFat Arduino libraries. Or check out the following MicroMod tutorials that have a built-in microSD card socket for ideas on data logging. Better yet, try adding a sensor and write some code to log some data!

MicroMod Weather Carrier Board Hookup Guide

MicroMod Data Logging Carrier Board Hookup Guide

MicroMod Asset Tracker Carrier Board Hookup Guide

Looking for more examples with a Function Board? Below are a few Function Board examples from our tutorials that are tagged with MicroMod.

1W LoRa MicroMod Function Board Hookup Guide

MicroMod WiFi Function Board - ESP32 Hookup Guide

MicroMod Environmental Function Board Hookup Guide

MicroMod WiFi Function Board - DA16200 Hookup Guide

Better yet, try connecting a Qwiic-enabled device to the Main Board's Qwiic connector. Below are a few examples from our tutorials that are tagged with Qwiic.

Qwiic Differential I2C Bus Extender (PCA9615) Hookup Guide

RedBoard Turbo Hookup Guide

Advanced Autonomous Kit for Sphero RVR Assembly Guide

SparkFun Air Quality Sensor - SGP30 (Qwiic) Hookup Guide

Troubleshooting

If you need technical assistance and more information on a product that is not working as you expected, we recommend heading on over to the SparkFun Technical Assistance page for some initial troubleshooting.

If you don't find what you need there, the SparkFun Forums: MicroMod are a great place to find and ask for help. If this is your first visit, you'll need to create a Forum Account to search product forums and post questions.

Resources and Going Further

Now that you've successfully got your MicroMod Main Board with a Processor Board, it's time to incorporate it into your own project! For more information, check out the resources below:

- MicroMod Main Board - Single

- MicroMod Main Board - Double

- SFE Product Showcase

Looking for more inspiration? Check out these other tutorials related to MicroMod.