How Lithium Polymer Batteries are Made

Electrode Preparation

The material that will be coated on to the anode and cathode is mixed.

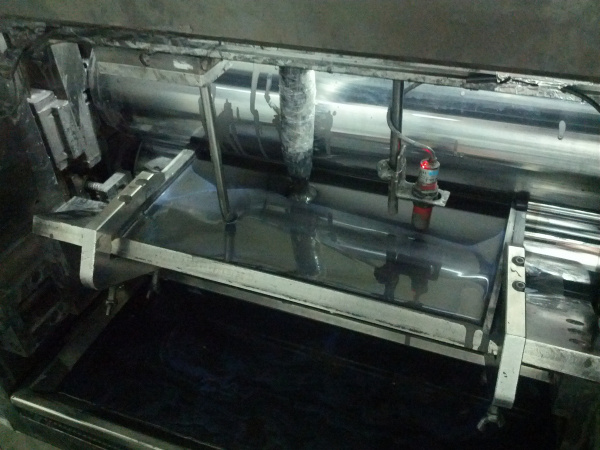

Large rolls of raw materials are loaded into the coating machine. I think this is aluminum.

A thin layer of the slurry of carbon and lithium material is applied in large square swaths onto the metal terminal material.

In a continuous fashion, the material is fed through an oven to cure the slurry onto the terminal. This room was probably 20m (65ft) long and pretty toasty.

There was two lines running continuously. One was the anode (I believe this is customarily aluminum) and one line was the cathode (copper). I remember this as a-a and c-c (copper is for cathode). Seen above is the never ending strip of copper with the carbon slurry cured in squares coming out of the oven. These squares will be cut and folded in the next few steps so don't be fooled into thinking they are making cells quite that big. Yet.

Lots of lots of raw electrodes ready for trimming.

This machine smashes the electrode like a pasta machine. In effect, making the sheets much thinner so that they can be folded more times.

Cutting the large sheets to proper width.