ELastoLite Hookup Guide

Assembly

ReplaceMeOpen

ReplaceMeClose

Now that you have all the parts and tools necessary, lets start assembling. First, plug the inverter into the USB cable and charge the inverter (you can use your computer port or a USB to wall socket power adapter). Lay out your fabric, and plot the path you’re going to want the circuitry to follow. Maintaining the shortest path possible is the main thing to conside. Also, do your best to route in a manner that keeps the connectors out of harms way such as areas where there with be lots movement, eg. shoulders, elbows, knees, etc. Another thing to consider is inverter placement. If it’s a garment, route it into a pocket. If not, make some form of support for it such as a pouch or straps. The circuitry will supply very little structural support for the heavy inverter, so you’re going to want to provide support to the inverter in another manner.

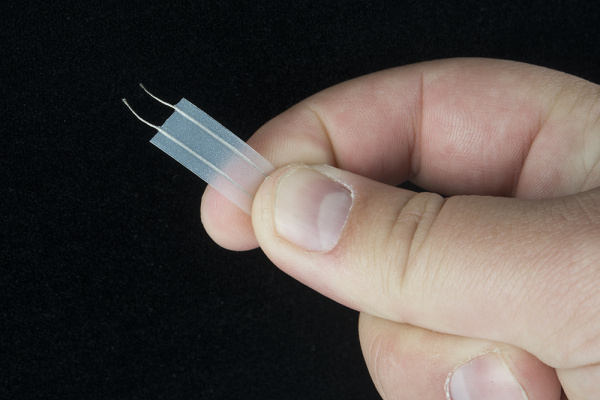

Once you have the circuitry cut to the length you need, you need to strip the ends. You’ll want about ⅕ of an inch on the end that will attach to the lamp and about ⅓ of inch on the end that will connect with the Molex connector. To strip the ends, simply take a hobby knife and make three incisions in the iron-on material perpendicular to the conductive thread. Be sure not to nick the thread as this could easily lead to a break in the thread after use. Once you have your three incisions, pull firmly yet lightly on the end of the iron-on sheath until it comes off, exposing the aforementioned lengths of thread.

Next, you need to decide whether you’re going to iron in the circuitry when making the connector or not. The process will be slightly easier if you do so now. If not, skip ahead to the part about making the inverter connection.

It’s time for some ironing. Go ahead and set the iron to the cotton setting. Once you have the circuitry path established, go ahead, and start ironing. Be sure to apply very little pressure as the weight of the iron will do most of the work, and keep everything as crease free as possible. Leave a couple of inches free at each end as it will be easier to work with when making the connections.

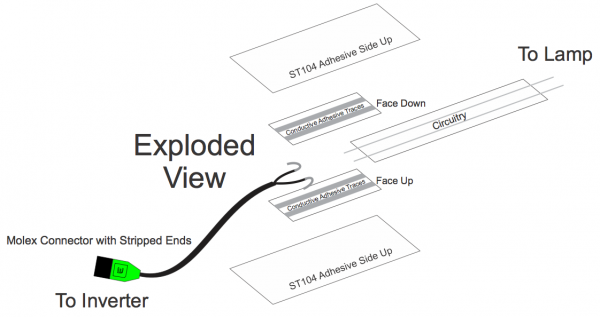

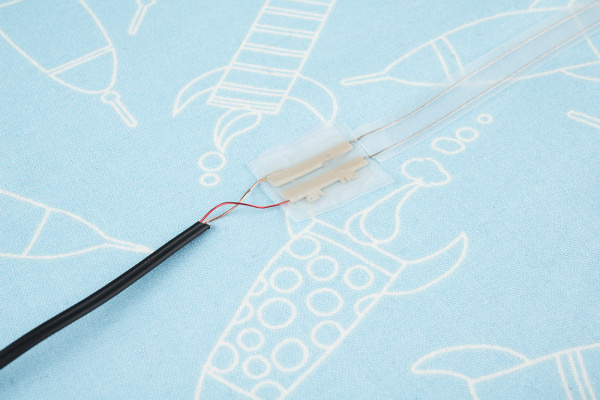

With the circuitry ironed in, we can start the molex connector assembly. Below is the exploded view of how it will go together. PLEASE READ THIS NEXT PART. The wire coming off molex connector is a bit deceiving. There are four wires, only two get used. The two wires we we'll be using are the red and tan wires. The other wires need to be clipped off. The remaining wires should be stripped. If not, gently strip ¼ of an inch of the wire with wire strippers. It doesn’t matter which wire goes on which side as we’re supplying AC power from the inverter to the lamp.

The straight connectors are going to be labeled with a “top” facing the direction that will go on the inside on the connection (the part you want touching the exposed wires). The iron-on tape that will form the outer layer of the connection needs to face a specific direction as well. You want the curve of the tape facing inward. If you can’t tell which side faces in, pinch it between your fingers and rub it back and forth. The side that sticks to your finger will face inward, and the side that faces out will slide across your finger. This is also the time to cut the tape in two equal pieces if you haven’t already.

If you’re not ironing this directly into the garment immediately, put some wax paper underneath before you bond the connector pieces. It’s imperative that the leads off the circuitry and the molex connector get sandwiched between the gray strips on each of the straight connectors. If they don’t sit in those strips, the connection won’t be made. Once you have everything in place like in the diagram above, place the iron over top for 10-15 seconds, then remove. Let it cool before handling it, the connection should be tightly secure. If you ironed the connection into the fabric when bonding it, make sure there’s no pockets of the circuitry that haven’t gotten ironed in (leave the lamp side loose still).

As I mentioned, the circuitry isn’t going to provide any support for the inverter, and you don’t want to risk the inverter pulling apart the bonded connection we just made between the circuitry and the molex connector. So, we’re going to sew in some support for the molex connector. I usually just sew an “X” over the outer insulation for the wire coming off the molex connector.

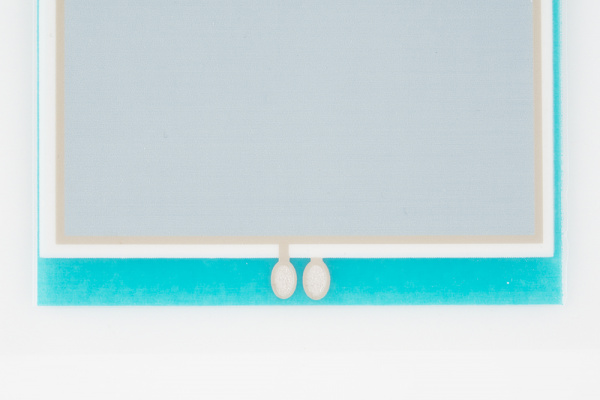

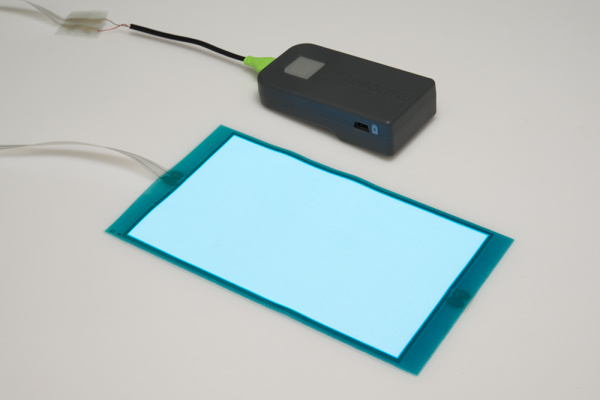

Now, we need to make the connection to the lamp. This connection is much more simple, thankfully. First, remove the lamp from the hard backing. If heat is applied too long, it could cause the lamp to bond to the backing. You’ll want the back (the side with the text on it) facing up, exposing the connection points (shown in the picture below).

Place the conductive thread over top the connection points then place the connection patch overtop with the letters “C P” facing up. Just like with the molex connection, sit the iron on top of the connection points for 10-15 seconds to make the bond. Let it cool, and insure the bond occurred and is stable. If not, there’s an extra connection patch that can be used to redo the bond.

Finally, if this is the last lamp in the daisy chain, you'll want use the third connection patch to close the exposed connection points as they will be live. Follow the steps previously outlined to make the connection to the conductive thread. Just omit the conductive thread from the process.

Fastening the ELastoLite Lamp to your garment requires a little bit of sewing. It is possible to purchase more of the conductive tape and iron it to the back of the lamp then iron that onto the garment (this is an approved method from Oryon Tech). However, you will still have the edges exposed. I personally recommend sewing a fabric frame around the lamp. This will also allow you to create a shape for the lamp as cutting it and retaining it’s waterproofing is not possible. If you want to create a shape where a lot of the lamp will be hidden, use a heavier fabric to prevent the lamp from shining through. Sewing in a frame will also allow for the potential to swap out lamps should something unfortunate happen to original.