Using EAGLE: Board Layout

Checking for Errors

Before we package the design up and send it off to the fabrication house, there are a few tools we can use to check our design for errors.

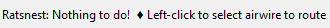

Ratsnest -- Nothing To Do!

The first check is to make sure you've actually routed all of the nets in your schematic. To do this, hit the RATSNEST icon --  -- and then immediately check the bottom left status box. If you've routed everything, it should say "Ratsnest: Nothing to do!"

-- and then immediately check the bottom left status box. If you've routed everything, it should say "Ratsnest: Nothing to do!"

As denoted by the exclamation mark, having "nothing to do" is very exciting. It means you've made every route required.

If ratsnest says you have "N airwires" left to route, double check your board for any floating golden lines and route them up. If you've looked all over, and can't find the suspect airwire, try turning off every layer except 19 Unrouted.

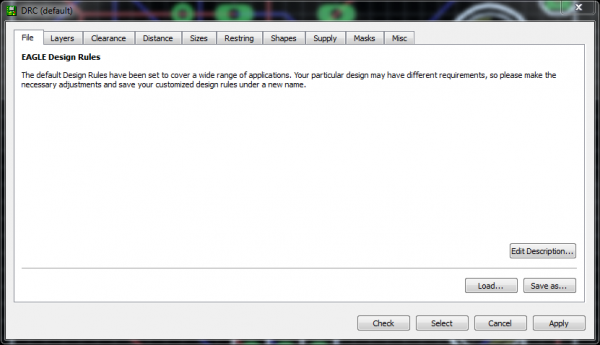

Design Rule Check

Once you're done routing there's just one more check to be made: the design rule check (DRC). For this step, we recommend you use the SparkFun design rules, which you can download here. To load up the DRC, click the DRC icon --  -- which opens up this dialog:

-- which opens up this dialog:

The tabs in this view (Layers, Clearance, Distance, etc.) help define a huge set of design rules which your layout needs to pass. These rules define things like minimum clearance distances, or trace widths, or drill hole sizes...all sorts of fun stuff. Instead of setting each of those manually, you can load up a set of design rules using a DRU file. To do this, hit Load... and select the SparkFun.dru file you just downloaded. The title of the window will change to "DRC (SparkFun)", and some values on the other tabs will change. Then hit the Check button.

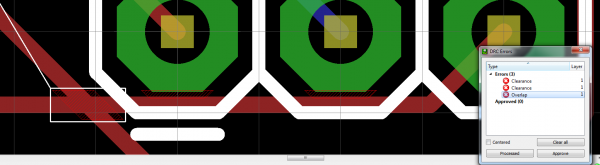

Again, look down to the bottom-left of the editor. If your design is perfect, you should see "DRC: No errors." But if things didn't go so swell, you'll instead be greeted by the dreaded "DRC Errors" window. The error window lists all of the open errors, and it also highlights where the error is. Click on any of the errors listed, and EAGLE will point to the offender.

There are all sorts of errors that the DRC can find, but here are some of the most common:

- Clearance: A trace is too close to either another trace or a via. You'll probably have to nudge the trace around using the MOVE tool.

- Overlap: Two different signal traces are overlapping each other. This will create a short if it's not fixed. You might have to RIPUP one trace, and try routing it on the other side of the board. Or find a new way for it to reach its destination.

- Dimension: A trace, pad, or via is intersecting with (or too close to) a dimension line. If this isn't fixed that part of the board will just be cut off.

Once you've seen both "No airwires left!" and "DRC: No errors.", your board is ready to send to the fab house, which means it's time to generate some gerber files. Before we do that though, let's add some finishing touches to the design.