Stepoko: Powered by grbl Hookup Guide

Hardware: Dealing with Heat

To get the heat out of the driver ICs, the Stepoko comes equipped with three heatsinks on the top and a large aluminum mass on the backside. When setting up the Stepoko, be careful to check the temperature often to make sure it is not too hot to touch. Generally speaking, the harder the motors are driven, the more heat will accumulate on the heatsinks.

Here are a few methods of dealing with the heatsinks.

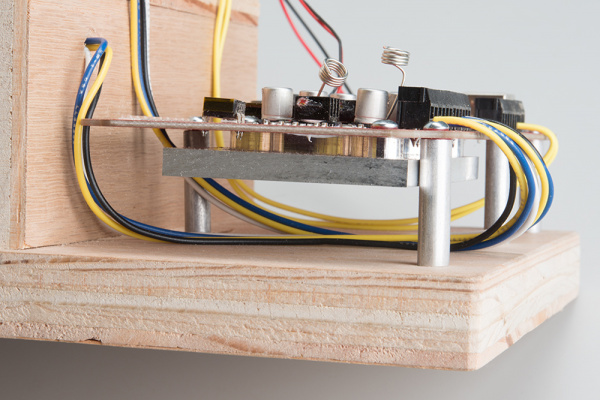

Provide air space

For small motors or mills that don't have a large cool mass of metal to wick out the heat, make sure the Stepoko is lofted and that air can passively circulate around the heatsinks.

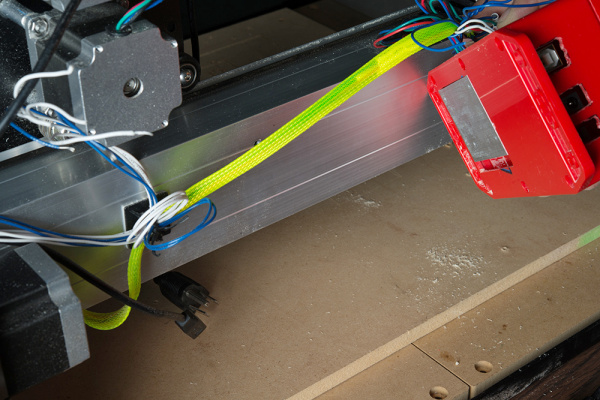

Attach a path for cooling

The intent of the aluminum slug on the backside is to conduct heat to the mill itself for cooling. The height is perfect to pass through a hole cut in the SparkFun Big Red Box enclosure so that the whole thing can be mounted to a thermally conducive surface.

Add a fan

There is a connection on the Stepoko for attaching a single, or multiple 12V fans. This connection is regulated to 12V and unswitched, so fans connected there will run whenever the Stepoko is powered from 12-30V.