Integrated Circuits

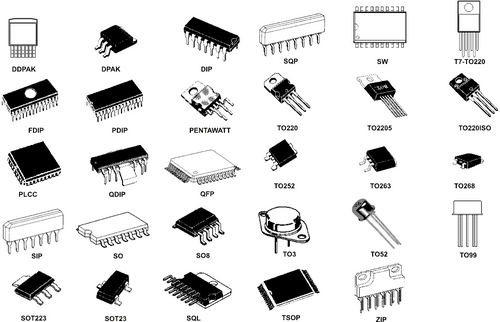

IC Packages

The package is what encapsulates the integrated circuit die and splays it out into a device we can more easily connect to. Each outer connection on the die is connected via a tiny piece of gold wire to a pad or pin on the package. Pins are the silver, extruding terminals on an IC, which go on to connect to other parts of a circuit. These are of utmost importance to us, because they're what will go on to connect to the rest of the components and wires in a circuit.

There are many different types of packages, each of which has unique dimensions, mounting-types, and/or pin-counts.

Polarity Marking and Pin Numbering

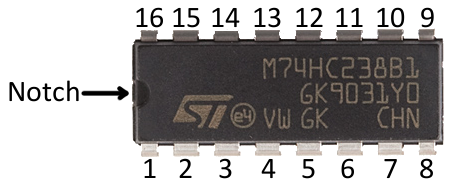

All ICs are polarized, and every pin is unique in terms of both location and function. This means the package has to have some way to convey which pin is which. Most ICs will use either a notch or a dot to indicate which pin is the first pin. (Sometimes both, sometimes one or the other.)

Once you know where the first pin is, the remaining pin numbers increase sequentially as you move counter-clockwise around the chip.

Mounting Style

One of the main distinguishing package type characteristics is the way they mount to a circuit board. All packages fall into one of two mounting types: through-hole (PTH) or surface-mount (SMD or SMT). Through-hole packages are generally bigger, and much easier to work with. They're designed to be stuck through one side of a board and soldered to the other side.

Surface-mount packages range in size from small to minuscule. They are all designed to sit on one side of a circuit board and be soldered to the surface. The pins of a SMD package either extrude out the side, perpendicular to the chip, or are sometimes arranged in a matrix on the bottom of the chip. ICs in this form factor are not very "hand-assembly-friendly." They usually require special tools to aid in the process.

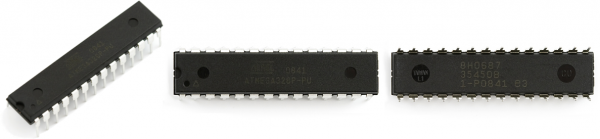

DIP (Dual in-line packages)

DIP, short for dual in-line package, is the most common through-hole IC package you'll encounter. These little chips have two parallel rows of pins extending perpendicularly out of a rectangular, black, plastic housing.

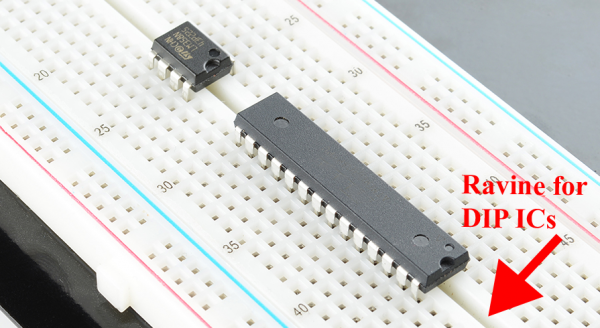

Each of the pins on a DIP IC are spaced by 0.1" (2.54mm), which is a standard spacing and perfect for fitting into breadboards and other prototyping boards. The overall dimensions of a DIP package depend on its pin count, which may be anywhere from four to 64.

The area between each row of pins is perfectly spaced to allow DIP ICs to straddle the center area of a breadboard. This provides each of the pins its own row in the board, and it makes sure they don't short to each other.

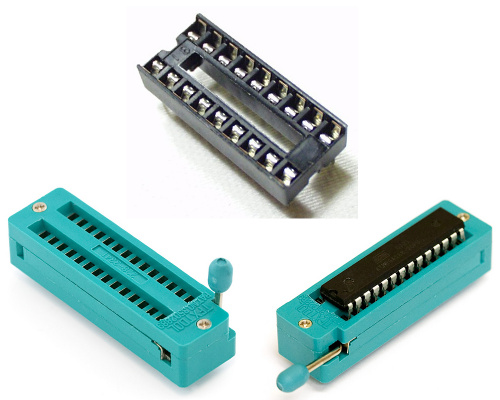

Aside from being used in breadboards, DIP ICs can also be soldered into PCBs. They're inserted into one side of the board and soldered into place on the other side. Sometimes, instead of soldering directly to the IC, it's a good idea to socket the chip. Using sockets allows for a DIP IC to be removed and swapped out, if it happens to "let its blue smoke out."

Surface-Mount (SMD/SMT) Packages

There is a huge variety of surface-mount package types these days. In order to work with surface-mount packaged ICs, you usually need a custom printed circuit board (PCB) made for them, which has a matching pattern of copper on which they're soldered.

Here are a few of the more common SMD package types out there, ranging in hand-solderability from "doable" to "doable, but only with special tools" to "doable only with very special, usually automated tools".

Small-Outline (SOP)

Small-outline IC (SOIC) packages are the surface-mount cousin of the DIP. It's what you'd get if you bent all the pins on a DIP outward, and shrunk it down to size. With a steady hand, and a close eye, these packages are among the easiest SMD parts to hand solder. On SOIC packages, each pin is usually spaced by about 0.05" (1.27mm) from the next.

The SSOP (shrink small-outline package) is an even smaller version of SOIC packages. Other, similar IC packages include TSOP (thin small-outline package) and TSSOP (thin-shrink small-outline package).

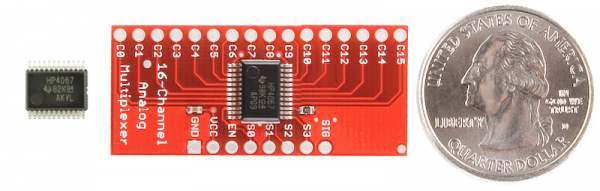

A lot of the more simple, single-task-oriented ICs like the MAX232 or multiplexers come in SOIC or SSOP forms.

Quad Flat Packages

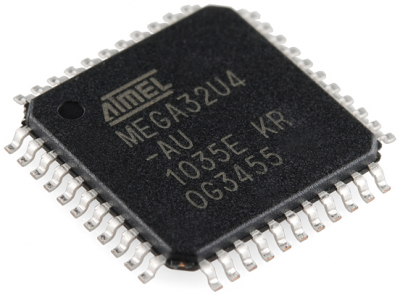

Splaying IC pins out in all four directions gets you something that might look like a quad flat package (QFP). QFP ICs might have anywhere from eight pins per side (32 total) to upwards of seventy (300+ total). The pins on a QFP IC are usually spaced by anywhere from 0.4mm to 1mm. Smaller variants of the standard QFP package include thin (TQFP), very thin (VQFP), and low-profile (LQFP) packages.

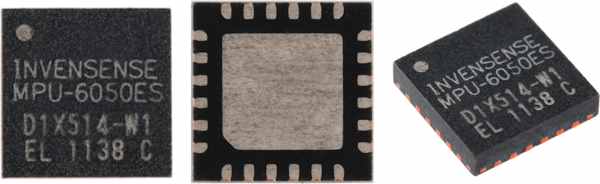

If you sanded the legs off a QFP IC, you get something that might look like a quad-flat no-leads (QFN) package. The connections on QFN packages are tiny, exposed pads on the bottom corner edges of the IC. Sometimes they wrap around, and are exposed on both the side and bottom, other packages only expose the pad on the bottom of the chip.

Thin (TQFN), very thin (VQFN), and micro-lead (MLF) packages are smaller variations of the standard QFN package. There are even dual no-lead (DFN) and thin-dual no-lead (TDFN) packages, which have pins on just two of the sides.

Many microprocessors, sensors, and other modern ICs come in QFP or QFN packages. The popular ATmega328 microcontroller is offered in both a TQFP package and a QFN-type (MLF) form, while a tiny accelerometer/gyroscope like the MPU-6050 comes in a miniscule QFN form.

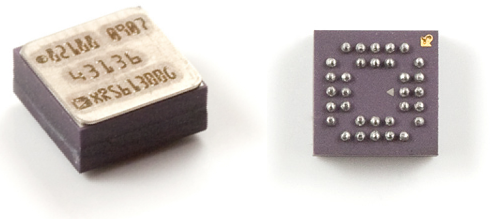

Ball Grid Arrays

Finally, for really advanced ICs, there are ball grid array (BGA) packages. These are amazingly intricate little packages where little balls of solder are arranged in a 2-D grid on the bottom of the IC. Sometimes the solder balls are attached directly to the die!

BGA packages are usually reserved for advanced microprocessors, like those on the pcDuino or Raspberry Pi.

If you can hand solder a BGA-packaged IC, consider yourself a master solderer. Usually, to put these packages onto a PCB requires an automated procedure involving pick-and-place machines and reflow ovens.