LilyPad Safety Scarf

Putting It Together

STEP 1:

Use an X-Acto Knife to cut the fabric around the LEDs back about one inch on one side of both of your LED ribbons.

STEP 2:

This will cause the ribbon to fray at the end.

Pull back the wires and use a pair of scissors to cut off the frayed material. Make sure not to cut the LED's wires.

STEP 3:

Apply Fray Check to the cut edge of each ribbon, and let it dry (~15 minutes).

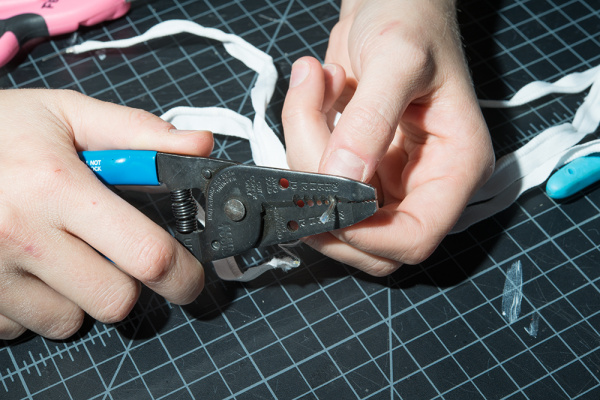

STEP 4:

Strip the exposed wire of LED strip. Notice one lead has a copper tint and one does not. The copper tinted lead is the anode, or '+' lead. For more information about polarity and LEDs, visit our tutorials about polarity and LEDs.

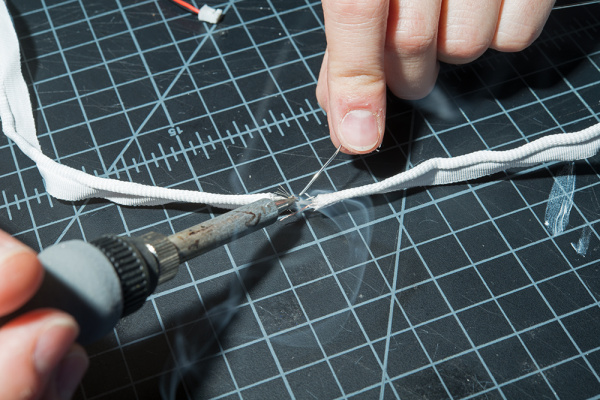

STEP 5:

Solder the two LED ribbons together. This can be tricky with the LED ribbons since there is no room to add heat shrink and the frayed wires can easily become crossed. To battle this, I soldered my anodes first and left a little space between the two ribbons. Then, I insulated them with hot glue before soldering the cathodes together. Make sure to insulate the cathode side after soldering them together.

STEP 6:

Cut a small rectangle of white felt. Fold it over the ribbon to hide the solder connections we just made. Hot glue it in place.

STEP 7:

You should have one long LED ribbon now. Repeat steps 1-4 on only one end of the new long ribbon. Cut about two 4-5 inch pieces of flexible silicone wire, soldering one to the exposed anode and one to the exposed cathode.

Insulate with heat shrink and then set aside for later.

STEP 8:

Cut your fabric according to the pattern. We used this lovely and easy to follow free cowl pattern by Purl Soho.

STEP 9:

Sew the lining pieces together. Then sew the outer pieces together, but stop before sewing the lining and the outer fabric together. Set the lining aside for later.

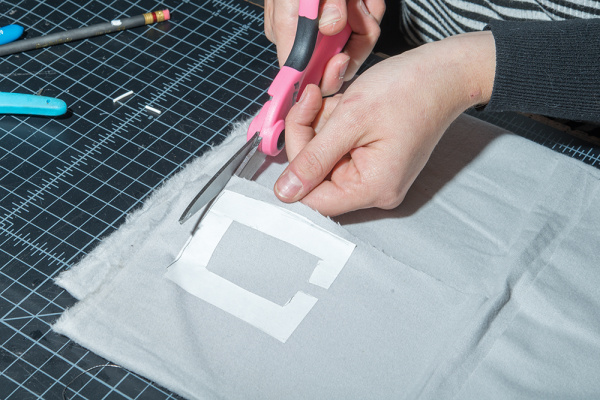

STEP 10:

Find the "right side" of the outer fabric. The right side is the side that will be facing the world when you wear the garment. Grab the LED ribbon, and pin it to the long edge of your outer fabric on the right side. The sew tab should be along the top edge of the fabric with the tube holding the LED strip pointing towards the center of the fabric as seen in the image below.

STEP 11:

When you reach the end of your fabric edge, cut the strip to the same length of the fabric.

STEP 12:

Add a touch of Fray Check to the edge of LED ribbon that you cut.

STEP 13:

Sew the LED ribbon down along the sew tab. Make sure to remove the pins as you go since this can break your sewing machine needle and cause problems with your stitch. When using a sewing machine, be careful to not sew into the LEDs and wires.

STEP 14:

Add a dab of hot glue to the bottom of your LilyPad Light Sensor and then place it on the right side of your fabric about an inch below the LED ribbon leads.

STEP 15:

Flip the fabric over to the "wrong side." The wrong side will be the inside of the cowl. Add some hot glue to the bottom of the LilyPad USB Plus and place it down about 1-2 inches below the light sensor (but on the opposite side!)

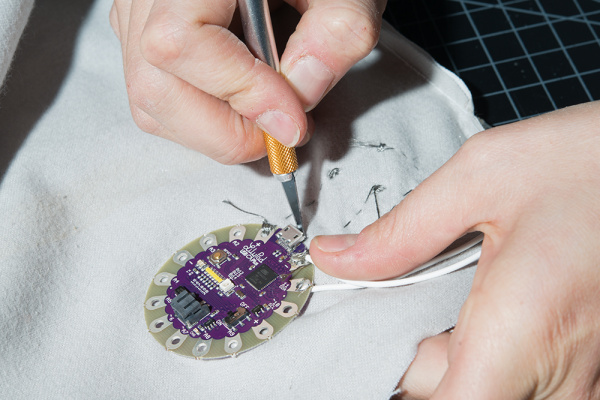

STEP 16:

Using conductive thread, sew the light sensor to the microcontroller according to the circuit diagram.

STEP 17:

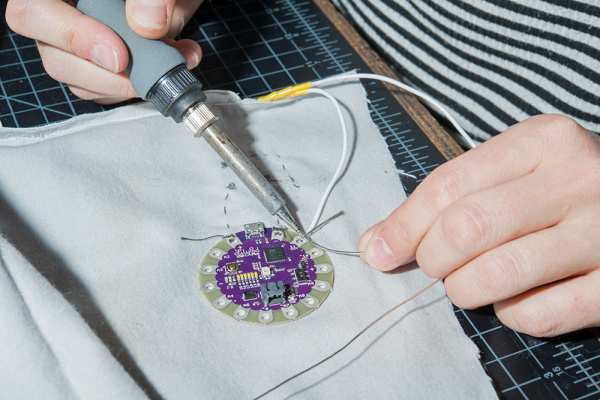

Strip the un-soldered side of both flexible silicone wires connected to the LED leads.

STEP 18:

Solder the anode ('+') lead connection to pin 11 on the LilyPad and the cathode ('-') lead to GND on the LilyPad.

STEP 19:

Cut a small hole directly above the USB cable connector. Make sure it is large enough to access that port from the opposite side of the fabric.

STEP 20:

Apply Fray Check around the cut edges of the hole. Make sure that the Fray Check does not get into the USB connector.

STEP 21:

Trim the excess conductive thread and test your circuit with a battery. Once everything is working, use some puff paint to insulate the traces on both the right and wrong side of the fabric.

STEP 22:

Place your battery on the iron-on adhesive and trace it.

STEP 23:

Draw a larger rectangle around the battery's trace and leave at least a half inch space between the lines.

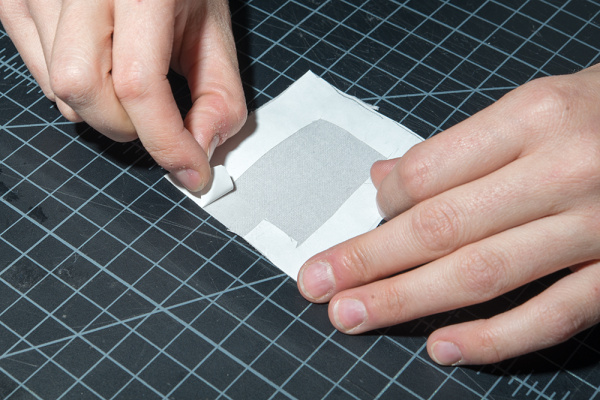

STEP 24:

Cut along the edge of the larger rectangle, and then cut out the battery tracing as well.

STEP 25:

With the paper side up, iron the iron-on adhesive to a scrap piece of fabric. Then cut the fabric along the edge of the adhesive.

STEP 26:

Peel the paper backing off of the iron-on adhesive.

STEP 27:

Plug your battery into the LilyPad's JST connector.

STEP 28:

Place the piece of fabric with the iron-on adhesive over of the battery. Make sure that the adhesive side is facing down.

STEP 29:

Being extremely careful to not touch the battery, and iron over the fabric where there is adhesive in order to make a battery holder.

STEP 30:

Finish sewing the scarf according to the pattern.

STEP 31:

Use your finger to feel for the ON/OFF switch on the LilyPad and then cut a small hole in the lining fabric to expose it.

STEP 32:

Add some Fray Check around the edge of the hole, and let dry.

STEP 33:

Turn it on by flipping the switch and enjoy!