How to Solder: Castellated Mounting Holes

Troubleshooting

This section will go over a few of the gotchas involved with Surface Mount Soldering.

Stubborn GND Pins

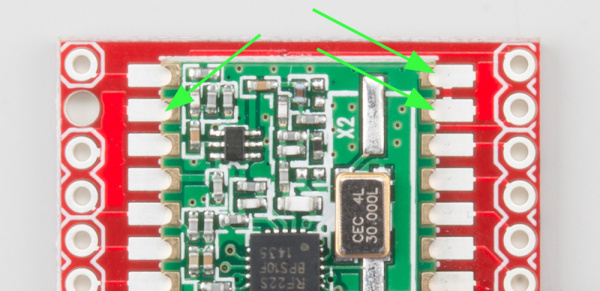

You may notice that just a few of the pins you're soldering are being more stubborn than others in that they don't want to accept the solder as willingly. This is due to the Ground (GND) plane (or pour). In PCB design, you can either make a connection with a trace (the tiny copper lines running all over PCBs) or you can create a plane or pour of copper (the light red blobs tucked in between the dark red PCB in the photo below). These are often connected to GND or Vcc, but can be connected to any signal you desire. No matter to which signal they are connected, this large plane of copper tends to absorb more heat than a skinny trace, which makes them slightly harder to solder.

If any pad in particular is giving you trouble, check to see if it's a pad connected to a pour. If so, take a few extra seconds heating up that pad before you apply solder. A little extra flux will help with stuborn pads as well.

Fixing Mistakes

What happens if you make a mistake, like soldering two pins together?

The easiest fix is to use a little bit of solder wick and some flux to remove the solder.

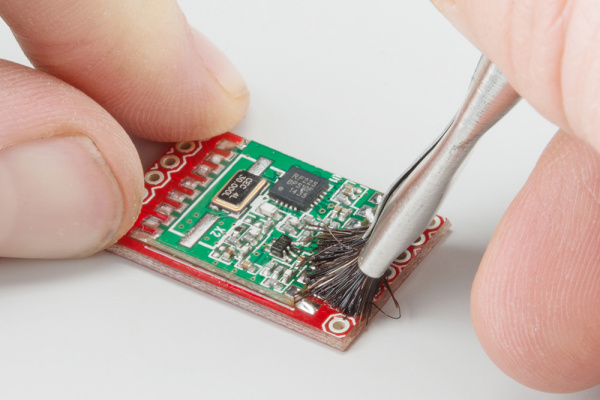

Prepare the Wick

If there is any solder on the end of the solder wick, clip it off. The solder will be silver in color.

Apply flux to the end of the wick. Most solder wick contains some flux, but it helps to add some more.

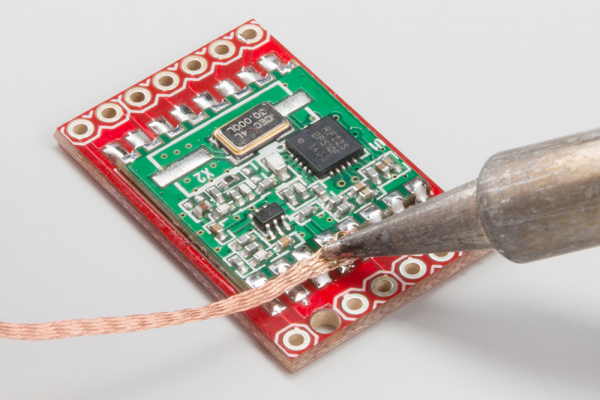

Remove Excess Solder

Hold the wick down on the solder bridge, and hold the soldering iron tip to the wick. Wait a few seconds, and the solder between the pins should be sucked up into the wick.

Fix the Pins

If you accidentally removed too much solder from a joint, you can simply add flux to the joint, hold the iron tip to the joint, and add a little more solder.

Clean the Joint

Any time you add flux or solder (which likely contains flux) to a joint, you will want to clean it with a brush and some rubbing alcohol.

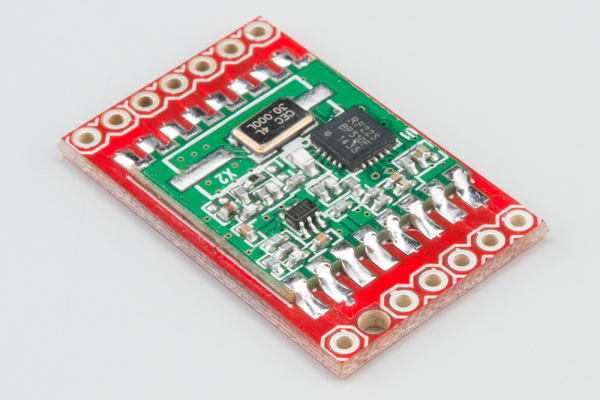

Inspect Your Work

Inspect the joints again to make sure the bridge has been removed and there is good solder deposition across all the pins.