Continuous Rotation Servo Trigger Hookup Guide

Continuous Rotation Servo Motors

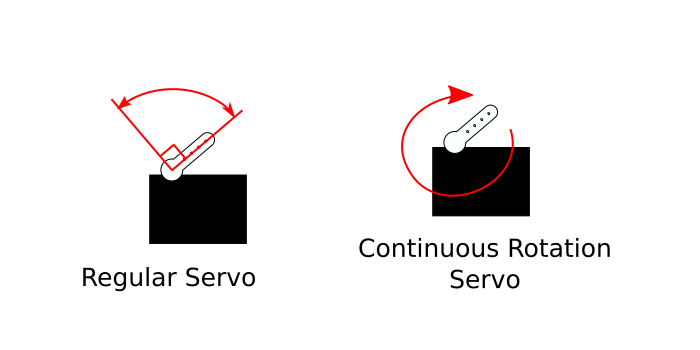

A continuous rotation servo (sometimes called a full rotation or 360° servo) looks like a regular hobby servo. While a regular servo motor only turns over a narrow range, with precise control over position, a continuous rotation servo has a shaft that spins continuously, with control over its speed and direction.

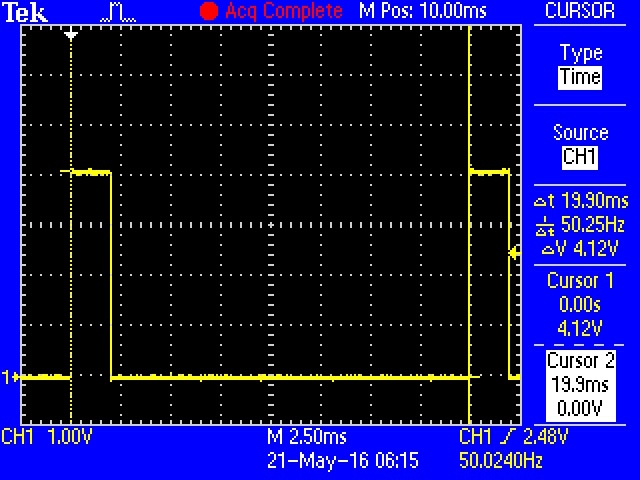

The control is performed using a pulse train signal, typically with pulses that vary from 1 to 2 milliseconds, sent every 20 milliseconds (50 Hz). A one millisecond pulse corresponds to full speed in one direction, while a two millisecond pulse is full speed in the other direction. These pulses are easy to generate using the pulse-width-modulation hardware on a modest microcontroller.

Halfway between those extremes, a 1.5 millisecond pulse should cause the motor to stop. Most CR servos have an adjustment screw or trimpot that allows you to fine tune the point at which it stops, a calibration procedure often called nulling.

With the CR Servo Trigger, the stop point can be adjusted on the board, but if it behaves unexpectedly, double check that the trim on the servo itself isn't the root of the problem.