Beefcake Relay Control Hookup Guide

Assembly

The Beefcake Relay Control kit is relatively straight forward to assemble. This section outlines what tools will be needed and shows the assembly process.

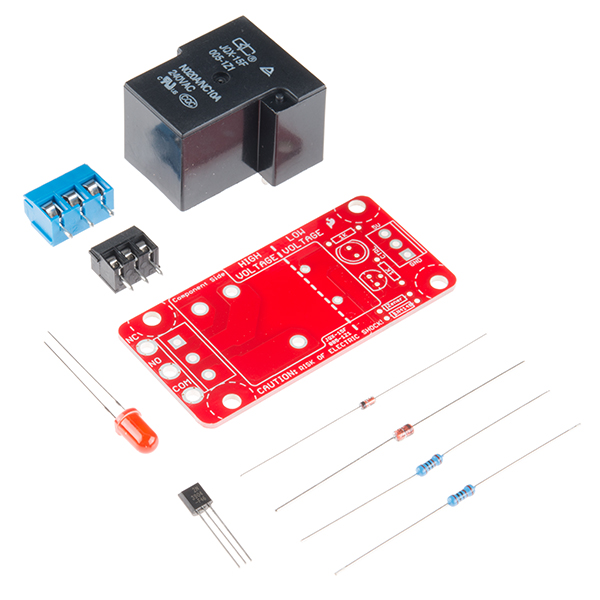

Materials

The kit contains the following parts:

- An electromechanical Relay

- 2x Terminal blocks, light gauge for signal and heavy for output

- Coil-active LED

- Bipolar junction transistor (BJT)

- 2x Current limiting resistors

- Flyback arrestor diode

- Zener diode for discharge

Tools

The following tools are recommended.

- A soldering iron with 50 watts of power capability.

- Some solder, either leaded or lead-free.

- A magnifying glass or loupe.

- A vise to hold the PCB as you work.

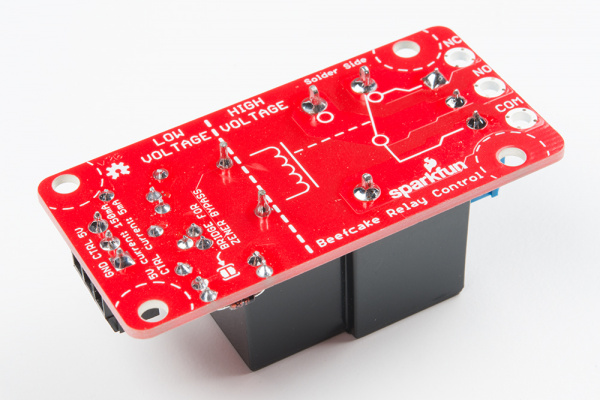

Building The Beefcake Relay Control

The Beefcake uses standard through-hole techniques. Components will be passed through the holes, soldered, and the leads trimmed. It's best to start with the shortest components working up to the taller ones. This is so they stay pressed in place while the board is upside down against a work surface.

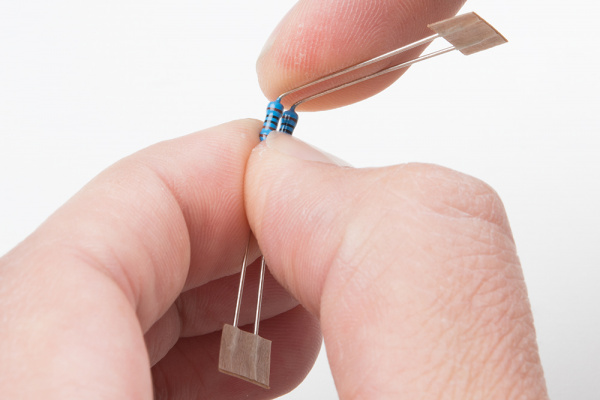

Start with the resistors. Bend the leads so they form 90 degree angles as close to the resistor body as possible.

Feed them into the place marked 1k. They will sit over the silkscreen box.

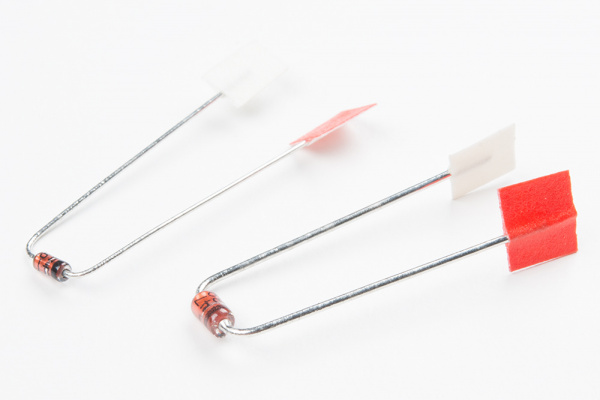

Next, bend the diode leads. The diode bodies are shorter, so it's not necessary to get the bends right close. They should be the same widths as the resistors after bending.

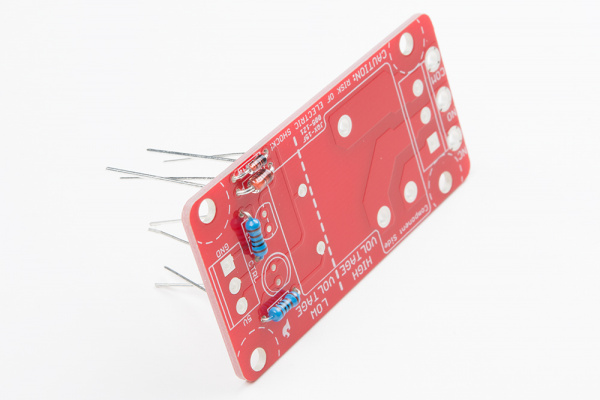

Insert the diodes. The fat diode is the 9.1V zener, and should be marked 4739. Place it over the silkscreen box labled "Zener" with the black band towards the white silkscreen stripe. The smaller diode should be labled 4148 and is a standard high-speed diode. Place it over the box labled N4148 with the black stripe towards the silk stripe.

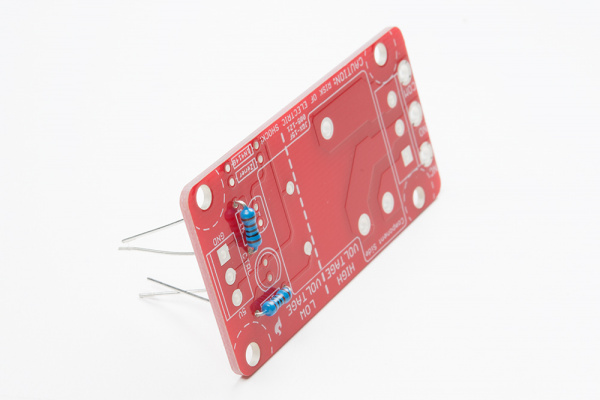

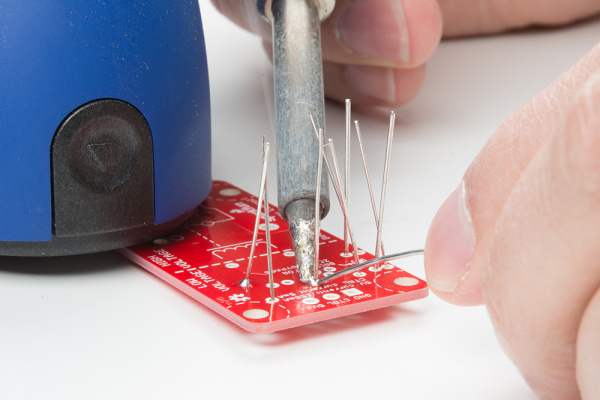

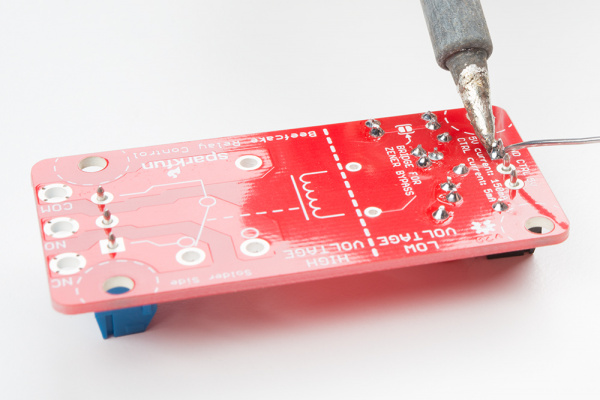

Now, flip the board, and solder those components forming nice shiny cones around the leads. A weight, like the solder stand, can be used to hold the board, or it can be placed in a vice.

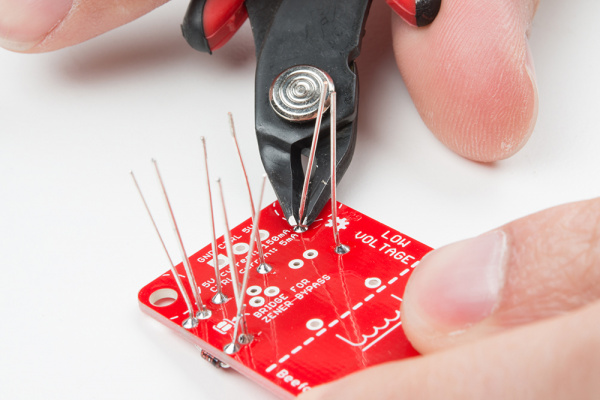

Clip the component leads right at the top of the solder cones.

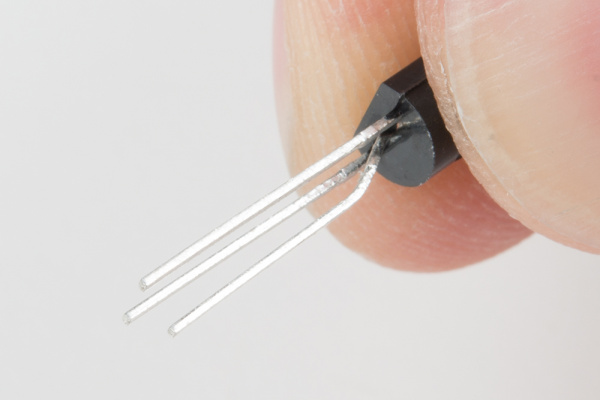

Next, prepare the BJT. Leave the outer two legs straight. Bend the inner leg in an 'S' curve so that it is spaced evenly from the other two legs in an equilateral triangle.

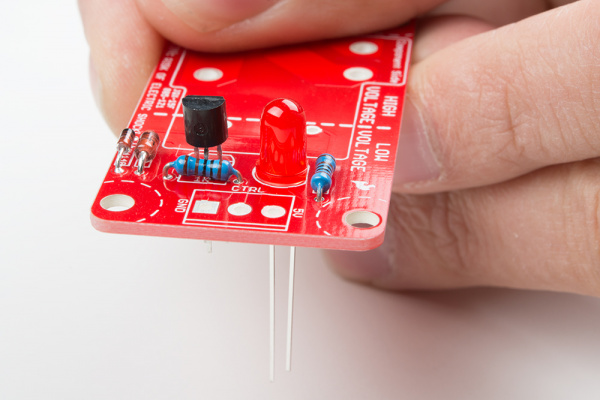

Fit the BJT and LED into the board, minding that the flat side of the LED matches the flat part of the silkscreen circle.

Solder them in place, and trim the leads.

Attach the screw terminals. Orient them so the apertures face outward. These will stay in pretty well, so flip it and solder in place.

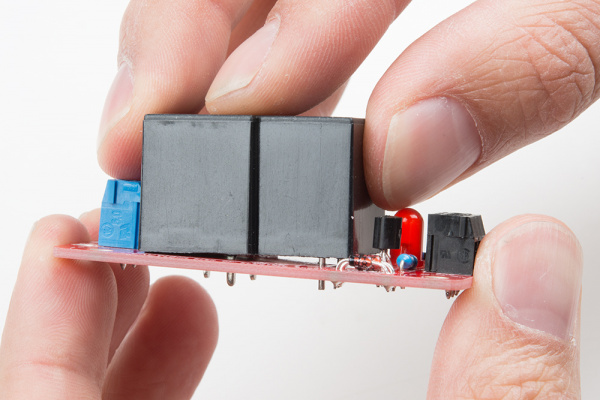

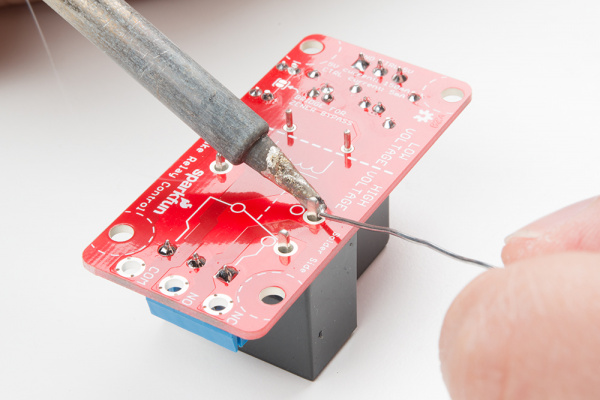

The last component is the relay. The relay has thick leads for current capacity, so they may need a little work getting inserted. Once they are all positioned, it should sit flush with the PCB.

The extra copper involved in carrying the current means it can take extra heat to get the solder to flow, but it is very important. A cold solder joint will cause extra resistance. With the recommended Hakko iron set to 700 degrees, there should be no problem, but the iron will have to be held on longer than normal. Feed extra solder if the joint is looking dirty, the flux will come out, and you can scoop away the extra solder with the iron right after.

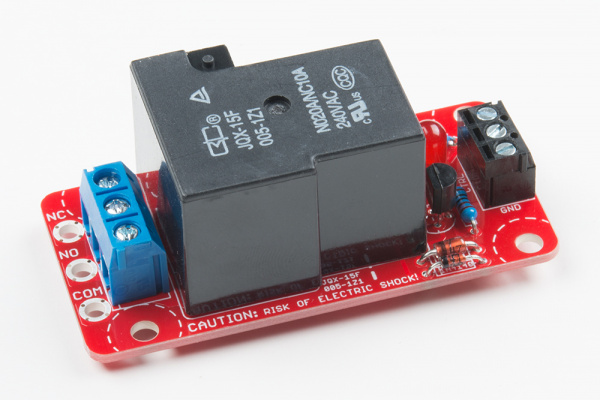

Congratulations! You now have a completed Beefcake Relay Control circuit. Here's what the final product will look like.