Sewing with Conductive Thread

This Tutorial is Retired!

This tutorial covers concepts or technologies that are no longer current. It's still here for you to read and enjoy, but may not be as useful as our newest tutorials.

View the updated tutorial: LilyPad Basics: E-Sewing

How Do I Choose the Best Conductive Thread For My Project?

There are many types of conductive thread, but in the interest of brevity, I'm going to focus on the ones SparkFun carries; they fit into two categories.

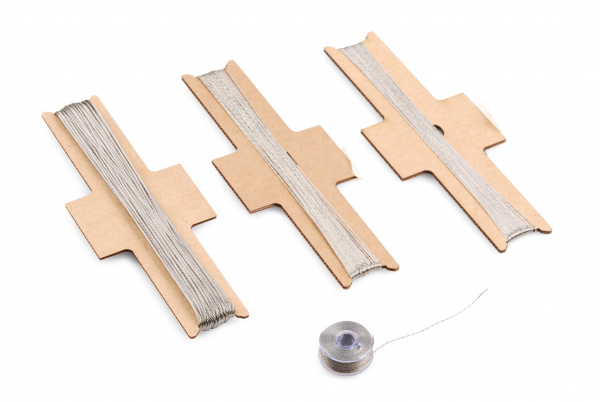

First, we have silver-coated threads. These are nylon thread, like you've seen before, but they've been coated with silver, which is conductive. The resistance of silver threads can vary a great deal. If your project is large (think a quilt, or a circuit that spans an entire full-length dress), make sure you check the resistance of the thread you are considering against the needs of your circuit. If your project is small (a painting canvas, a t-shirt, anything where the traces won’t go more than a couple of feet) and the acceptable resistance is high, silver is great! Our finest, easiest to use thread is the 2-ply silver, which is hand sewable and useable as a top and bobbin thread in most sewing machines. Because the base of these silver threads is nylon, they're completely incompatible with soldering. The nylon interior of the thread is just too susceptible to heat; it can't take the temperature necessary to melt solder.

Second, we have stainless steel threads, which are a little bit different. There is no traditional thread core; these threads are made entirely of stainless steel. They're a little bit more difficult to sew with because they can be a bit 'twisty', but they make up for it with very reliable (and low) resistance. If you've got a project in mind that requires very long traces (more than a few feet), you’ll need low resistance. Currently, our lowest resistance threads are all stainless, so that’s where you’ll want to start. The lowest resistance threads are VERY thick, more like twine than thread, and can't really be stitched. These are great to use in casings, piping, or stitched down with embroidery or a machine zig-zig stitch.

Because these threads are composed entirely of stainless steel, they're much more soldering-friendly. The heat of a soldering iron won't damage the thread (although it will discolor it a bit, so be warned), so you can solder on, near, or to the thread. Do be aware that stainless steel is not an easy material to solder to, so you've still got a tough job ahead if you want to solder something directly to the thread.

Choosing the correct thread is very project-specific. Your safest bet on a complicated project is to calculate the resistance your circuit can handle using Ohm's Law. Divide that resistance by the feet of distance you anticipate between your power supply and components, and look for the thinnest thread of that resistance or less. If that all sounds a little bit complicated, don’t worry. You can use trial and error to get a feel for which threads work best for you, and most projects don’t require the lowest resistance available. The stainless steel bobbin is an excellent starting point. It’s useable by hand or in a sewing machine and relatively low resistance (about 28 ohms per foot.) It’s also cheap, so it’s a small commitment. If you DO find that your resistance is too high, it’s not a hard fix. Every time you add another strand of the same thread to the trace, you halve the resistance. If you don’t want to remove and replace the traces, you can pass back over them to bring the resistance down to an acceptable level.