Motors and Selecting the Right One

Linear Motors - The Future!!!

The future is linear! In high-speed pick and place machines speed is everything. With speed comes friction, with friction comes maintanence, with maintanance comes downtime, with downtime comes lost productivity. By removing the components needed to transfer rotary to linear motion, the system becomes much lighter and more efficient. Linear motors are simple to maintain, and, with only one moving part, are incredibly reliable. Did I mention they are incredibly fast?! This is the pick and place machine we are using in production, and it is incredibly fast! This machine also packs such a punch, there is a warning for pacemakers on it. There is an entire row of high-power, rare-earth magnets.

The Anatomy of a Linear Motor

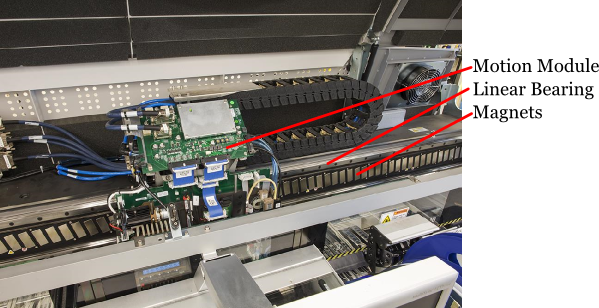

To better understand how one works, let's look inside our pick and place machine downstairs.

- Motion Module - Contains electromagnets and controller.

- Magnets - Provide a magnetic field for the coils to attract and repel

- Linear Bearning - Keeps the motor in alignment with magnets and is the only moving part.

Theory of Operation

The mechanics of a linear motor is nearly identical to a brushless motor. The only difference is if you were to take a brushless motor and unfold it into a straight line you'd have a linear motor. The Motion Module is the only moving part. Where things become complicated is orchestrating the sequence of energizing coils. The polarity of each coil is controlled by the direction of current flow. The animation demonstrates a simple pattern that controllers would follow. Alternating current changes the polarity giving each coil a "push/pull" effect. In a linear motor, there is typically an encoder or some advanced positioning system to keep track of the location of the Motion Module. To reach a high position accuracy, the controllers are much more complicated than anything found on a conventional system. Microstepping is a method to "throttle" the magnets to provide smooth and precise motion. To achieve this though, linear motors require a highly specialized controller tuned for each motor. As controller technology improves, we are likely to see these motors decrease in price. Maybe someday our 3D printers will print in seconds and not hours!

Pros

- Reliable

- High speed

- Efficient

- No rotary to linear conversion required

Cons

- Expensive

- Require custom controllers

- Purpose built for each system

- Did I mention expensive?