Motors and Selecting the Right One

DC Brush Motors - The Classic

The DC brush motor is one of the simplest motors in use today. You can find these motors just about anywhere. They are in household appliances, toys, and automobiles. Being simple to construct and control, these motors are the go-to solution for professionals and hobbyists alike.

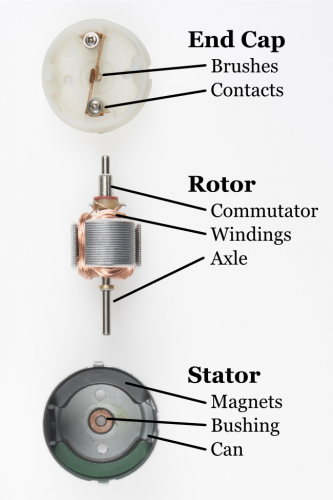

The Anatomy of a Brush Motor

To better understand how one works, let's start by tearing down a simple hobby motor. As you can see, they are simple in construction, comprising of a few key components.

- Brushes - Delivers power from the contacts to the armature through the commutator

- Contacts - Brings power from the controller to the brushes

- Commutator - Delivers power to the appropriate set of windings as the armature rotates

- Windings - Converts electricity to a magnetic field that drives the axle

- Axle - Transfers the mechanical power of the motor to the user application

- Magnets - Provide a magnetic field for the windings to attract and repel

- Bushing - Minimizes friction for the axle

- Can - Provides a mechanical casing for the motor

Theory of Operation

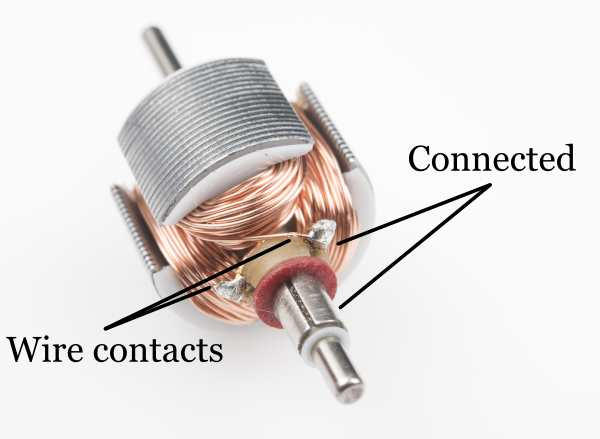

As the windings are energized, they attract to the magnets located around the motor. This rotates the motor until the brushes make contact with a new set of commutator contacts. This new contact energizes a new set of windings and starts the process again. To reverse the direction of the motor, simply reverse the polarity on the motor contacts. Sparks inside a brush motor are produced by the brush jumping to the next contact. Each wire of a coil is connected to the two closest commutator contacts.

An odd number of windings is always used to prevent the motor from getting locked into a steady state. Larger motors also use more sets of windings to help eliminate "cogging," thus providing smooth control at low revolutions per minute (RPMs). Cogging can be demonstrated by rotating the motor axle by hand. You will feel "bumps" in the motion where the magnets are closest to the exposed stator. Cogging can be eliminated with a few tricks in design, but the most prevalent is removing the stator all together. These types of motors are referred to as ironless or coreless motors.

Pros

- Simple to control

- Excellent torque at low RPM

- Inexpensive and mass produced

Cons

- Brushes can wear out over time

- Brush arcing can generate electromagnetic noise

- Usually limited in speed due to brush heating