MicroMod STM32 Processor Hookup Guide

Introduction

We've brought the power and precision of the STM32 Processor to the MicroMod ecosystem! Please welcome the MicroMod STM32 Processor Board! With the high-performance Arm® Cortex®-M4 32-bit RISC core, Flash memory up to 1 Mbyte, up to 192 Kbytes of SRAM, a memory protection unit (MPU), high-speed embedded memories, up to 4 Kbytes of backup SRAM, and an extensive range of enhanced I/Os and peripherals, this board is ready to rock your MicroMod world. Let's dive in!

Required Materials

To follow along with this tutorial, you will need the following materials. You may not need everything though depending on what you have. Add it to your cart, read through the guide, and adjust the cart as necessary.

Suggested Reading

The SparkFun MicroMod ecosystem offers a unique way to allow users to customize their project to their needs. Do you want to send your weather data via a wireless signal (e.g. Bluetooth or WiFi)? There's a MicroMod Processor Board for that. Looking to instead maximize efficiency and processing power? You guessed it, there's a MicroMod Processor Board for that. If you are not familiar with the MicroMod ecosystem, take a look here:

If you aren't familiar with the MicroMod ecosystem, we recommend reading here for an overview.

|

| MicroMod Ecosystem |

We also recommend reading through the following tutorials if you are not familiar with the concepts covered in them:

Serial Communication

Getting Started with MicroMod

Hardware Overview

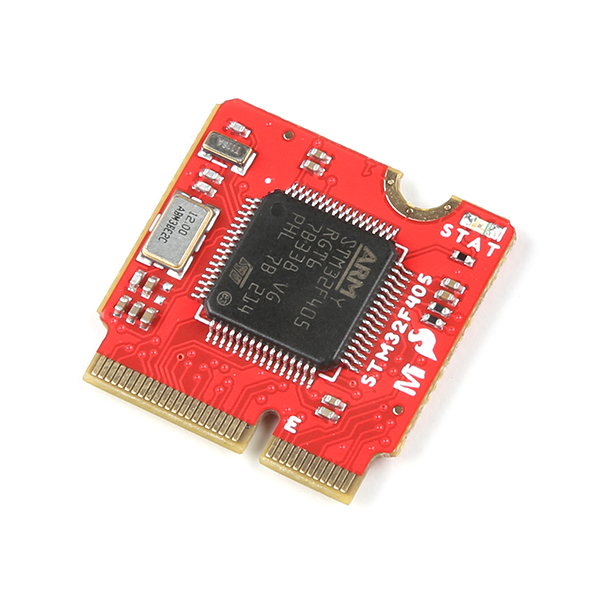

M.2 Connector

All of our MicroMod Processor boards come equipped with the M.2 MicroMod Connector, which leverages the M.2 standard and specification to allow you to install your MicroMod Processor board on your choice of carrier board.

|

|

| M.2 Connector from the Front | M.2 Connector from the Back |

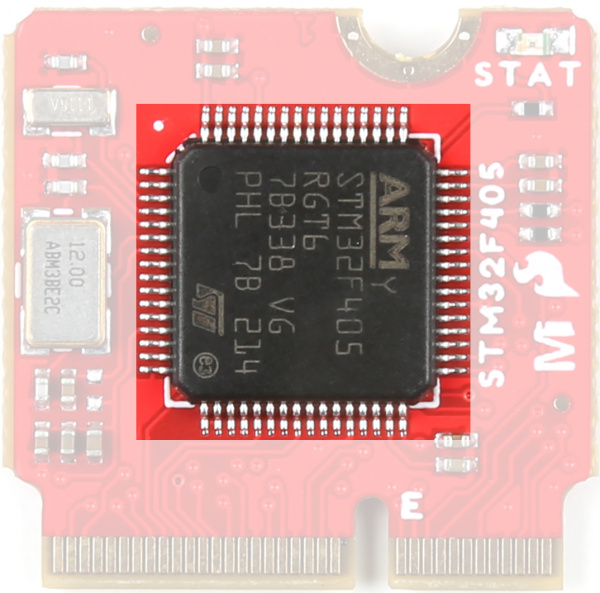

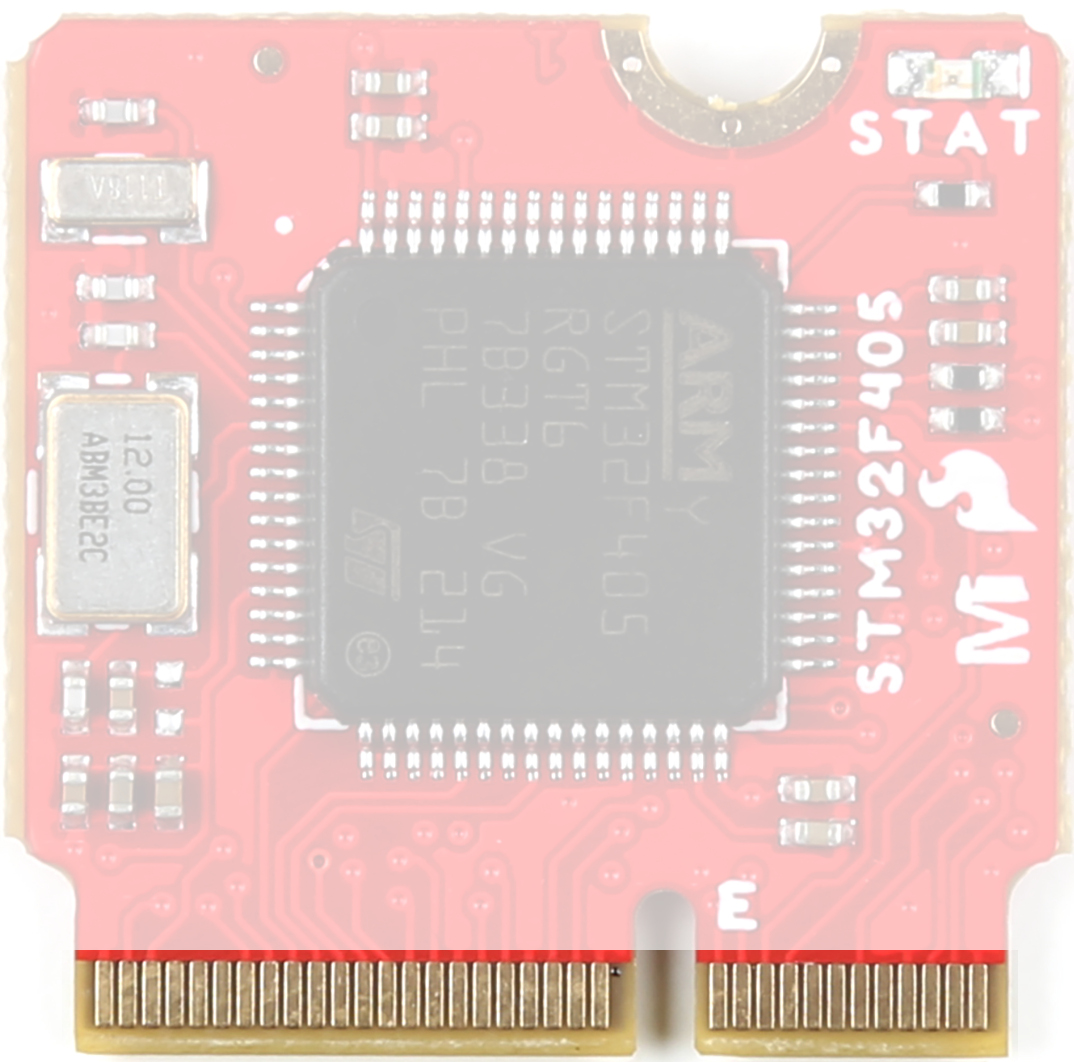

STM32F405

There is so much packed into this chip! As stated in the introduction, STMicroelectronics' STM32F405RG family is based on the ARM Cortex M4 RISC core. At 168MHz, it provides very high performance, floating point single precision, a full set of DSP instructions, and a memory protection unit that enhances application security. For more information, refer to the Datasheet.

Power

Power is supplied by the carrier board, but it should be noted that all pins are 3.3V.

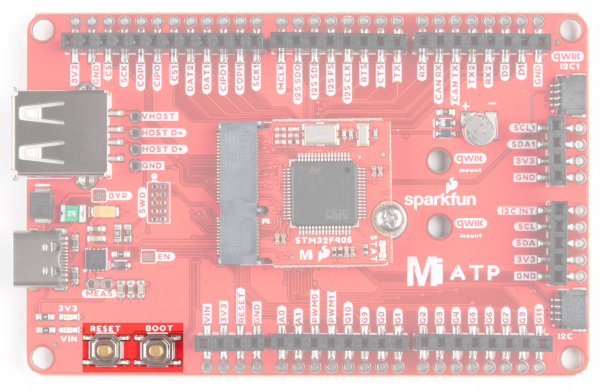

Boot and Reset Buttons

In order to upload code to the STM32 MicroMod Processor Board, you'll need these two buttons to put the board into Boot mode. Hold the Boot button down, press the Reset button (while still holding the Boot button), and then release the Boot button.

These pins will be on the carrier board. For this tutorial, we will show you the these pins on the MicroMod ATP Carrier board.

Flash

To complement the STM32F405 processor, we've added an additional 128Mb (16MB) serial flash memory chip.

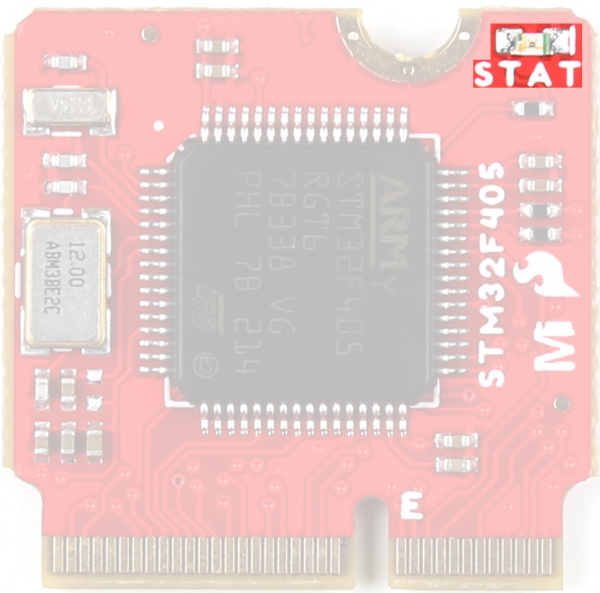

Status LED

MicroMod STM32F405 Processor Pin Functionality

The complete pin map can be found in the table below or you can refer to the schematic.

| AUDIO | UART | GPIO/BUS | I2C | SDIO | SPI | Dedicated |

| STM32 Pin | Primary Function | Bottom Pin |

Top Pin |

Primary Function | STM32 Pin |

|---|---|---|---|---|---|

| - | (Not Connected) | 75 | GND | - | |

| - | 3.3V | 74 | 73 | G5 / BUS5 | PC13 |

| - | - | 72 | 71 | G6 / BUS6 | PC2 |

| - | - | 70 | 69 | - | - |

| - | - | 68 | 67 | - | - |

| - | - | 66 | 65 | - | - |

| - | - | 64 | 63 | G10/HOST_VBUS | PB13 |

| - | - | 62 | 61 | SPI_PICO (I) | PA6 |

| - | - | 60 | 59 | SPI_POCI (O) | PA7 |

| - | - | 58 | 57 | SPI_SCK (O) | PA5 |

| PB4 | AUD_OUT | 56 | 55 | SPI_CS# | PC4 |

| PB5 | AUD_IN | 54 | 53 | I2C_SCL1 (I/O) | PB6 |

| PA4 | AUD_LRCLK | 52 | 51 | I2C_SDA1 (I/O) | PB7 |

| PB3 | AUD_BCLK | 50 | 49 | BATT_VIN / 3 (I - ADC) (0 to 3.3V) | - |

| PC9 | G4 / BUS4 | 48 | 47 | PWM1 | PC7 |

| PC8 | G3 / BUS3 | 46 | 45 | GND | - |

| PA0 | G2 / BUS2 | 44 | 43 | CAN_TX | PB9 |

| PA8 | G1 / BUS1 | 42 | 41 | CAN_RX | PB8 |

| PD2 | G0 / BUS0 | 40 | 39 | GND | - |

| PB0 | A1 | 38 | 37 | USBHOST_D- | PB14 |

| - | GND | 36 | 35 | USBHOST_D+ | PB15 |

| PC5 | A0 | 34 | 33 | GND | - |

| PC6 | PWM0 | 32 | 31 | Module Key | - |

| - | Module Key | 30 | 29 | Module Key | - |

| - | Module Key | 28 | 27 | Module Key | - |

| - | Module Key | 26 | 25 | Module Key | - |

| - | Module Key | 24 | 23 | SWDIO | PA13 |

| - | - | 22 | 21 | SWCLK | PA14 |

| - | - | 20 | 19 | UART_RX1 (I) | PA10 |

| PC1 | D1 | 18 | 17 | UART_TX1 (0) | PA9 |

| PB1 | I2C_INT# | 16 | 15 | - | - |

| PB10 | I2C_SCL (I/0) | 14 | 13 | - | - |

| PB11 | I2C_SDA (I/0) | 12 | 11 | BOOT# (I - Open Drain) | BOOT0 |

| PC0 | D0 | 10 | 9 | - | - |

| PB12 | G11/HOST_ID | 8 | 7 | GND | - |

| - | RESET# (I - Open Drain) | 6 | 5 | USB_D- | PA11 |

| - | - | 4 | 3 | USB_D+ | PA12 |

| - | 3.3V | 2 | 1 | GND | - |

| Function | Bottom Pin |

Top Pin |

Function | ||||||

|---|---|---|---|---|---|---|---|---|---|

| (Not Connected) | 75 | GND | |||||||

| 3.3V | 74 | 73 | G5 / BUS5 | ||||||

| RTC_3V_BATT | 72 | 71 | G6 / BUS6 | ||||||

| SPI_CS1# | SDIO_DATA3 (I/O) | 70 | 69 | G7 / BUS7 | |||||

| SDIO_DATA2 (I/O) | 68 | 67 | G8 | ||||||

| SDIO_DATA1 (I/O) | 66 | 65 | G9 | ADC_D- | CAM_HSYNC | ||||

| SPI_PICO1 | SDIO_DATA0 (I/O) | 64 | 63 | G10 | ADC_D+ | CAM_VSYNC | |||

| SPI POCI1 | SDIO_CMD (I/O) | 62 | 61 | SPI_PICO (I) | |||||

| SPI SCK1 | SDIO_SCK (O) | 60 | 59 | SPI_POCI (O) | LED_DAT | ||||

| AUD_MCLK (O) | 58 | 57 | SPI_SCK (O) | LED_CLK | |||||

| CAM_MCLK | PCM_OUT | I2S_OUT | AUD_OUT | 56 | 55 | SPI_CS# | |||

| CAM_PCLK | PCM_IN | I2S_IN | AUD_IN | 54 | 53 | I2C_SCL1 (I/O) | |||

| PDM_DATA | PCM_SYNC | I2S_WS | AUD_LRCLK | 52 | 51 | I2C_SDA1 (I/O) | |||

| PDM_CLK | PCM_CLK | I2S_SCK | AUD_BCLK | 50 | 49 | BATT_VIN / 3 (I - ADC) (0 to 3.3V) | |||

| G4 / BUS4 | 48 | 47 | PWM1 | ||||||

| G3 / BUS3 | 46 | 45 | GND | ||||||

| G2 / BUS2 | 44 | 43 | CAN_TX | ||||||

| G1 / BUS1 | 42 | 41 | CAN_RX | ||||||

| G0 / BUS0 | 40 | 39 | GND | ||||||

| A1 | 38 | 37 | USBHOST_D- | ||||||

| GND | 36 | 35 | USBHOST_D+ | ||||||

| A0 | 34 | 33 | GND | ||||||

| PWM0 | 32 | 31 | Module Key | ||||||

| Module Key | 30 | 29 | Module Key | ||||||

| Module Key | 28 | 27 | Module Key | ||||||

| Module Key | 26 | 25 | Module Key | ||||||

| Module Key | 24 | 23 | SWDIO | ||||||

| UART_TX2 (O) | 22 | 21 | SWDCK | ||||||

| UART_RX2 (I) | 20 | 19 | UART_RX1 (I) | ||||||

| CAM_TRIG | D1 | 18 | 17 | UART_TX1 (0) | |||||

| I2C_INT# | 16 | 15 | UART_CTS1 (I) | ||||||

| I2C_SCL (I/0) | 14 | 13 | UART_RTS1 (O) | ||||||

| I2C_SDA (I/0) | 12 | 11 | BOOT (I - Open Drain) | ||||||

| D0 | 10 | 9 | USB_VIN | ||||||

| SWO | G11 | 8 | 7 | GND | |||||

| RESET# (I - Open Drain) | 6 | 5 | USB_D- | ||||||

| 3.3V_EN | 4 | 3 | USB_D+ | ||||||

| 3.3V | 2 | 1 | GND | ||||||

| Signal Group | Signal | I/O | Description | Voltage | Power | 3.3V | I | 3.3V Source | 3.3V |

|---|---|---|---|---|

| GND | Return current path | 0V | ||

| USB_VIN | I | USB VIN compliant to USB 2.0 specification. Connect to pins on processor board that require 5V for USB functionality | 4.8-5.2V | |

| RTC_3V_BATT | I | 3V provided by external coin cell or mini battery. Max draw=100μA. Connect to pins maintaining an RTC during power loss. Can be left NC. | 3V | |

| 3.3V_EN | O | Controls the carrier board's main voltage regulator. Voltage above 1V will enable 3.3V power path. | 3.3V | |

| BATT_VIN/3 | I | Carrier board raw voltage over 3. 1/3 resistor divider is implemented on carrier board. Amplify the analog signal as needed for full 0-3.3V range | 3.3V | |

| Reset | Reset | I | Input to processor. Open drain with pullup on processor board. Pulling low resets processor. | 3.3V |

| Boot | I | Input to processor. Open drain with pullup on processor board. Pulling low puts processor into special boot mode. Can be left NC. | 3.3V | |

| USB | USB_D± | I/O | USB Data ±. Differential serial data interface compliant to USB 2.0 specification. If UART is required for programming, USB± must be routed to a USB-to-serial conversion IC on the processor board. | |

| USB Host | USBHOST_D± | I/O | For processors that support USB Host Mode. USB Data±. Differential serial data interface compliant to USB 2.0 specification. Can be left NC. | |

| CAN | CAN_RX | I | CAN Bus receive data. | 3.3V |

| CAN_TX | O | CAN Bus transmit data. | 3.3V | |

| UART | UART_RX1 | I | UART receive data. | 3.3V |

| UART_TX1 | O | UART transmit data. | 3.3V | |

| UART_RTS1 | O | UART ready to send. | 3.3V | |

| UART_CTS1 | I | UART clear to send. | 3.3V | |

| UART_RX2 | I | 2nd UART receive data. | 3.3V | |

| UART_TX2 | O | 2nd UART transmit data. | 3.3V | |

| I2C | I2C_SCL | I/O | I2C clock. Open drain with pullup on carrier board. | 3.3V |

| I2C_SDA | I/O | I2C data. Open drain with pullup on carrier board | 3.3V | |

| I2C_INT# | I | Interrupt notification from carrier board to processor. Open drain with pullup on carrier board. Active LOW | 3.3V | |

| I2C_SCL1 | I/O | 2nd I2C clock. Open drain with pullup on carrier board. | 3.3V | |

| I2C_SDA1 | I/O | 2nd I2C data. Open drain with pullup on carrier board. | 3.3V | |

| SPI | SPI_POCI | O | SPI Controller Output/Peripheral Input. | 3.3V |

| SPI_PICO | I | SPI Controller Input/Peripheral Output. | 3.3V | |

| SPI_SCK | O | SPI Clock. | 3.3V | |

| SPI_CS# | O | SPI Chip Select. Active LOW. Can be routed to GPIO if hardware CS is unused. | 3.3V | |

| SPI/SDIO | SPI_SCK1/SDIO_CLK | O | 2nd SPI Clock. Secondary use is SDIO Clock. | 3.3V |

| SPI_POCI1/SDIO_CMD | I/O | 2nd SPI Controller Output/Peripheral Input. Secondary use is SDIO command interface. | 3.3V | |

| SPI_PICO1/SDIO_DATA0 | I/O | 2nd SPI Peripheral Input/Controller Output. Secondary use is SDIO data exchange bit 0. | 3.3V | |

| SDIO_DATA1 | I/O | SDIO data exchange bit 1. | 3.3V | |

| SDIO_DATA2 | I/O | SDIO data exchange bit 2. | 3.3V | |

| SPI_CS1/SDIO_DATA3 | I/O | 2nd SPI Chip Select. Secondary use is SDIO data exchange bit 3. | 3.3V | |

| Audio | AUD_MCLK | O | Audio master clock. | 3.3V |

| AUD_OUT/PCM_OUT/I2S_OUT/CAM_MCLK | O | Audio data output. PCM synchronous data output. I2S serial data out. Camera master clock. | 3.3V | |

| AUD_IN/PCM_IN/I2S_IN/CAM_PCLK | I | Audio data input. PCM syncrhonous data input. I2S serial data in. Camera periphperal clock. | 3.3V | |

| AUD_LRCLK/PCM_SYNC/I2S_WS/PDM_DATA | I/O | Audio left/right clock. PCM syncrhonous data SYNC. I2S word select. PDM data. | 3.3V | |

| AUD_BCLK/PCM_CLK/I2S_CLK/PDM_CLK | O | Audio bit clock. PCM clock. I2S continuous serial clock. PDM clock. | 3.3V | |

| SWD | SWDIO | I/O | Serial Wire Debug I/O. Connect if processor board supports SWD. Can be left NC. | 3.3V |

| SWDCK | I | Serial Wire Debug clock. Connect if processor board supports SWD. Can be left NC. | 3.3V | |

| ADC | A0 | I | Analog to digital converter 0. Amplify the analog signal as needed to enable full 0-3.3V range. | 3.3V |

| A1 | I | Analog to digital converter 1. Amplify the analog signal as needed to enable full 0-3.3V range. | 3.3V | |

| PWM | PWM0 | O | Pulse width modulated output 0. | 3.3V |

| PWM1 | O | Pulse width modulated output 1. | 3.3V | |

| Digital | D0 | I/O | General digital input/output pin. | 3.3V |

| D1/CAM_TRIG | I/O | General digital input/output pin. Camera trigger. | 3.3V | |

| General/Bus | G0/BUS0 | I/O | General purpose pins. Any unused processor pins should be assigned to Gx with ADC + PWM capable pins given priority (0, 1, 2, etc.) positions. The intent is to guarantee PWM, ADC and Digital Pin functionality on respective ADC/PWM/Digital pins. Gx pins do not guarantee ADC/PWM function. Alternative use is pins can support a fast read/write 8-bit or 4-bit wide bus. | 3.3V |

| G1/BUS1 | I/O | 3.3V | ||

| G2/BUS2 | I/O | 3.3V | ||

| G3/BUS3 | I/O | 3.3V | ||

| G4/BUS4 | I/O | 3.3V | ||

| G5/BUS5 | I/O | 3.3V | ||

| G6/BUS6 | I/O | 3.3V | ||

| G7/BUS7 | I/O | 3.3V | ||

| G8 | I/O | General purpose pin | 3.3V | |

| G9/ADC_D-/CAM_HSYNC | I/O | Differential ADC input if available. Camera horizontal sync. | 3.3V | |

| G10/ADC_D+/CAM_VSYNC | I/O | Differential ADC input if available. Camera vertical sync. | 3.3V | |

| G11/SWO | I/O | General purpose pin. Serial Wire Output | 3.3V |

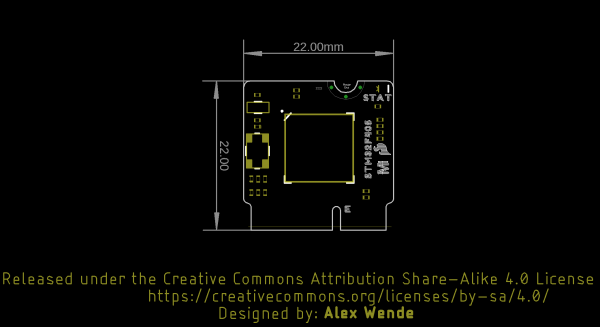

Board Outline

The board takes advantage of the standard MicroMod form factor.

Hardware Assembly

If you have not already, make sure to check out the Getting Started with MicroMod: Hardware Hookup for information on inserting your Processor Board into your Carrier Board.

Getting Started with MicroMod

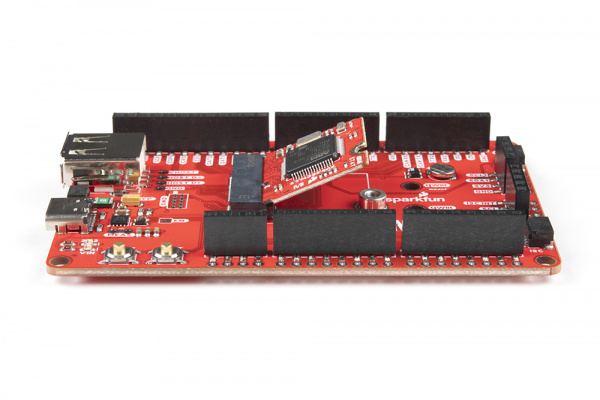

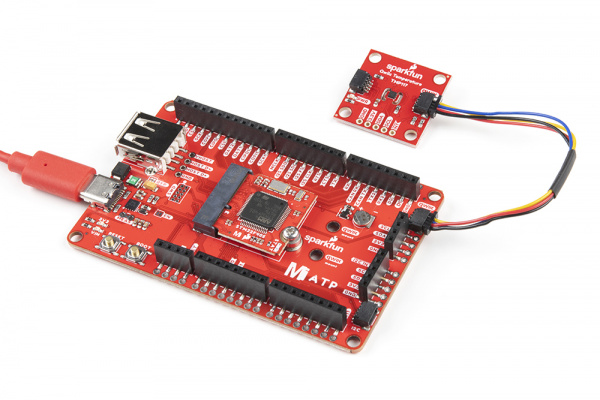

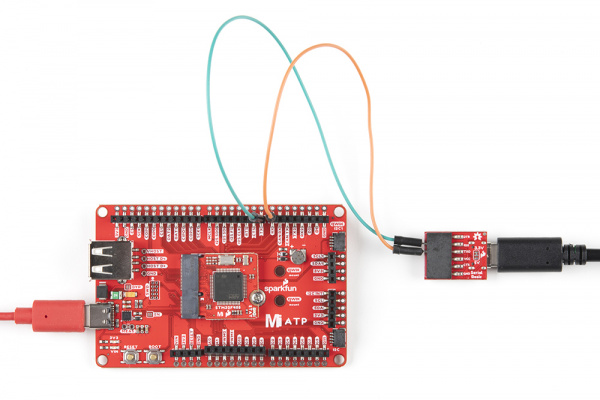

After inserting the MicroMod STM32 processor board into a carrier board, your setup may look like the following:

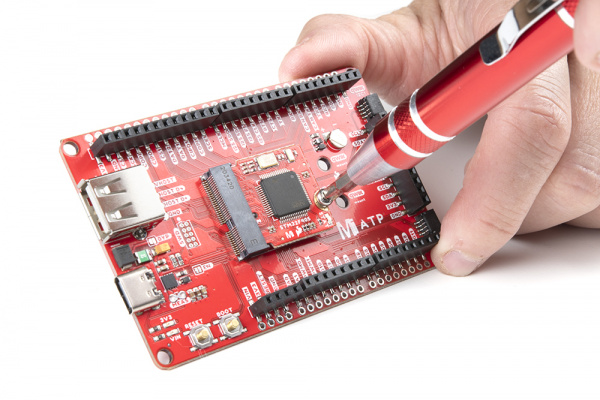

Go ahead and secure the Processor Board by gently pressing it down and tightening the screw (not too much though).

Software Setup and Programming

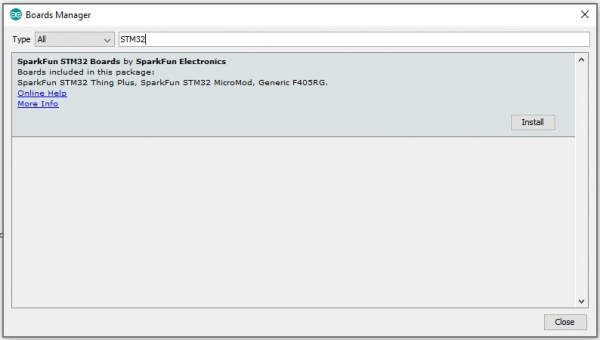

Arduino Board Definition

Installation for the STM32 MicroMod Processor is relatively straight-forward. You will want to install the board definitions via the Arduino Boards manager. Search for SparkFun STM32 and you should see the option for the STM32 MicroMod Processor show up.

For more information on installing boards via the Arduino Board Manager, check out the add-ons section of our Installing Arduino IDE tutorial.

Installing Arduino IDE

Install STM32Cube Programmer Software

In order to work with the STM32 MicroMod Processor, you'll need to install the STM32Cube Programmer. This is an all-in-one multi-OS software tool for programming STM32 products. It primarily provides the driver we need, but you can also program your board using this GUI.

DFU Bootloader

As of this writing, SparkFun is using the DFU bootloader to upload code to the STM32 MicroMod Processor. In order to do so, you need to do the following:

- Press and hold down the Boot button

- Press and release the Reset button while continuing to press the Boot button

- Keep pressing the Boot button until the code is uploaded

Examples

Blink

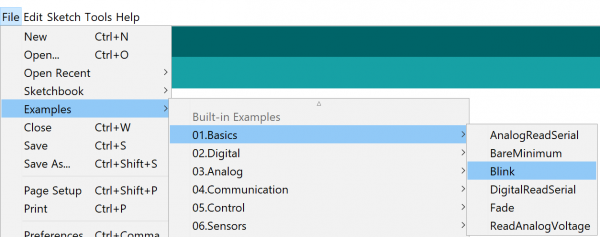

Let's start with something basic - let's blink an LED. Go to File->Examples->01.Basics->Blink.

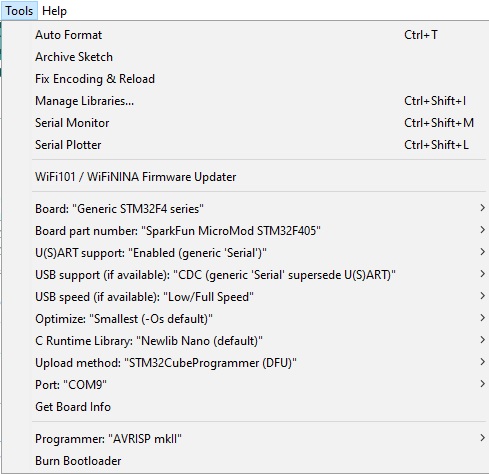

Once you've plugged your MicroMod Carrier Board with your MicroMod STM32 Processor into your computer, you'll need to go to your Tools menu and set up your options to look like the following:

With everything setup correctly, you'll need to put the Carrier Board into Boot Mode in order to upload the code.

- Press and hold down the Boot button

- Press and release the Reset button while continuing to press the Boot button

- Release the Boot button and press the Upload button in your Arduino IDE

Once the code finishes transferring, you should see the STAT LED on the STM32 Processor Board begin to blink!

I2C Scanner

The Qwiic Connect Ecosystem makes attaching sensors a breeze. That said, sometimes it's nice to be able to scan your I2C connections to find out the address of your sensor. That's what we'll do here!

Grab your MicroMod STM32 Processor Board and your Carrier Board, and attach a Qwiic Sensor to the Qwiic port on the Carrier like so:

Copy and paste the code below into a new Arduino sketch.

language:c

// --------------------------------------

// I2C Scanner example using Wire1

//

//

// This sketch tests the standard 7-bit addresses

// Devices with higher bit address might not be seen properly.

//

#include <Wire.h>

TwoWire Wire1(SDA1,SCL1); //Intialize Wire1 class

void setup()

{

Wire1.begin();

Serial.begin(115200);

while (!Serial); // Leonardo: wait for serial monitor

Serial.println("\nI2C Scanner");

}

void loop()

{

byte error, address;

int nDevices;

Serial.println("Scanning...");

nDevices = 0;

for(address = 1; address < 127; address++ )

{

// The i2c_scanner uses the return value of

// the Write.endTransmisstion to see if

// a device did acknowledge to the address.

Wire1.beginTransmission(address);

error = Wire1.endTransmission();

if (error == 0)

{

Serial.print("I2C device found at address 0x");

if (address<16)

Serial.print("0");

Serial.print(address,HEX);

Serial.println(" !");

nDevices++;

}

else if (error==4)

{

Serial.print("Unknown error at address 0x");

if (address<16)

Serial.print("0");

Serial.println(address,HEX);

}

}

if (nDevices == 0)

Serial.println("No I2C devices found\n");

else

Serial.println("done\n");

delay(5000); // wait 5 seconds for next scan

}

Make sure your options are all set up correctly in the Tools menu, and make sure you put the Carrier Board into Boot Mode in order to upload the code.

- Press and hold down the Boot button

- Press and release the Reset button while continuing to press the Boot button

- Release the Boot button and press the Upload button in your Arduino IDE

After uploading, open the serial monitor and set the baud to 115200. You should see a similar printout to the one shown below.

UART Example

Let's have a quick look at an example using UART. If you're unfamiliar with Serial Output, go ahead and have a look at our Serial Basic Tutorial.

Grab your MicroMod STM32 Processor Board and your Carrier Board, and attach the Serial Basic Rx and Tx pins like so:

Copy and paste the code below into a new Arduino sketch.

language:c

// --------------------------------------

// UART example using Serial1

//

//

// This sketch prints "Hello World!" every second

// using the secondary UART pins RX1 and TX1.

//

HardwareSerial Serial1(RX1, TX1); //Attach Serial1 to RX1 and TX1

void setup() {

Serial1.begin(115200);

while (!Serial1) {

; // wait for serial port to connect. Needed for Native USB only

}

Serial1.println("Goodnight moon!");

}

void loop() {

Serial1.println("Hello World!");

delay(1000);

}

Make sure your options are all set up correctly in the Tools menu, and make sure you put the Carrier Board into Boot Mode in order to upload the code.

- Press and hold down the Boot button

- Press and release the Reset button while continuing to press the Boot button

- Release the Boot button and press the Upload button in your Arduino IDE

Once your code is uploaded, open up the Serial Monitor attached to your Serial Basic with the baud rate set to 115200 to see your output!

Troubleshooting

If you need technical assistance and more information on a product that is not working as you expected, we recommend heading on over to the SparkFun Technical Assistance page for some initial troubleshooting.

If you don't find what you need there, the SparkFun Forums are a great place to find and ask for help. If this is your first visit, you'll need to create a Forum Account to search product forums and post questions.

Resources and Going Further

- MicroMod STM32 Processor Documentation

- MicroMod Documentation

- SparkFun MicroMod Interface v1.0 - Pinout (PDF)

- SparkFun MicroMod Interface v1.0 - Pin Descriptions (PDF)

- Getting Started with MicroMod

- Designing with MicroMod

- MicroMod Info Page

- MicroMod Forums

- SparkFun Eagle Libraries contains example footprints for the M.2 connector and SMD standoff

- M.2 MicroMod Connector Datasheet

- MicroMod Reflowable Standoff Datasheet

Need some inspiration for your next project? Check out some of these related tutorials using STM32:

STM32 Thing Plus Hookup Guide

Or check out other tutorials with MicroMod: