MicroMod Machine Learning Carrier Board Hookup Guide

Introduction

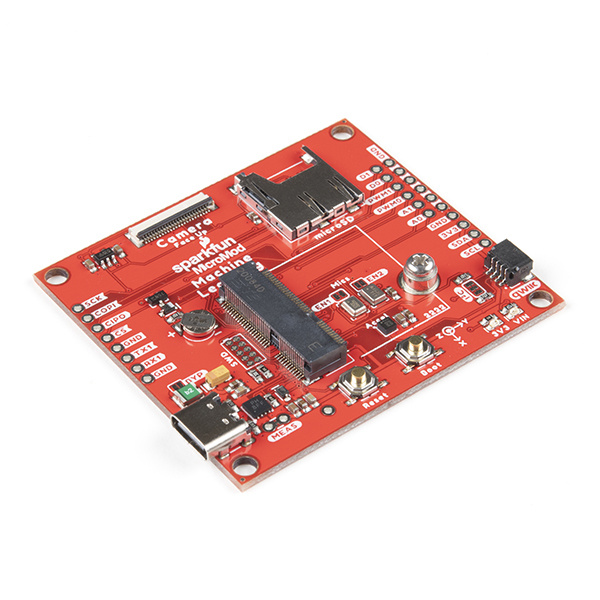

The MicroMod Machine Learning Carrier Board combines some of the features of our SparkFun Edge Board and SparkFun Artemis boards, but allows you the freedom to explore with any processor in the MicroMod lineup without the need for a central computer or web connection. Voice recognition, always-on voice commands, gesture, or image recognition are possible with TensorFlow applications. An on board accelerometer and Qwiic ports allow you even more flexibility.

Let's dive in, get a good look at what's available to us, and go over a few quick examples!

Required Materials

In addition to your Machine Learning carrier board, you'll need a processor board to get started. Here we use the Artemis Processor Board, but there are a number of others you can choose from.

You'll also need a USB-C cable to connect the Carrier to your computer and if you want to add some Qwiic breakouts to your MicroMod project you'll want at least one Qwiic cable to connect it all together. Below are some options for both of those cables:

Along with a processor and the pertinent cables and accessories, if you want to take full advantage of the features of the Machine Learning Carrier Board, you will need a microSD card:

microSD Card - 16GB (Class 10)

COM-15051Suggested Reading

The SparkFun MicroMod ecosystem is a unique way to allow users to customize their project to their needs. Do you want to send your weather data via a wireless signal (eg. Bluetooth or WiFi)? There's a MicroMod processor for that. Looking to instead maximize efficiency and processing power? You guessed it, there's a MicroMod processor for that.

|

| MicroMod Ecosystem |

We also recommend taking a look through the following tutorials if you are not familiar with the concepts covered in them:

Getting Started with MicroMod

MicroMod Artemis Processor Board Hookup Guide

Designing with MicroMod

Hardware Overview

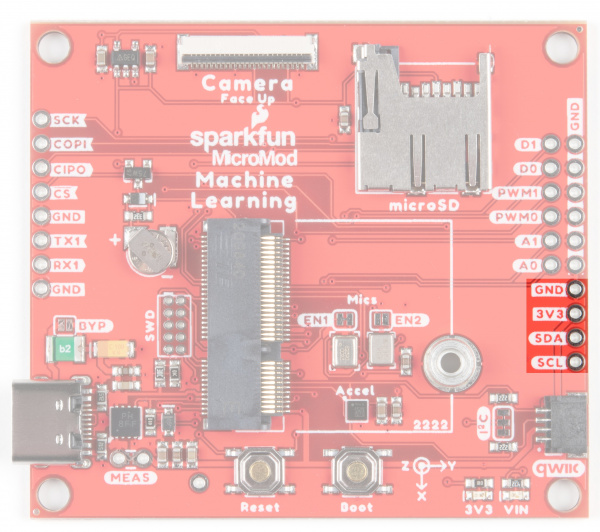

Common Components

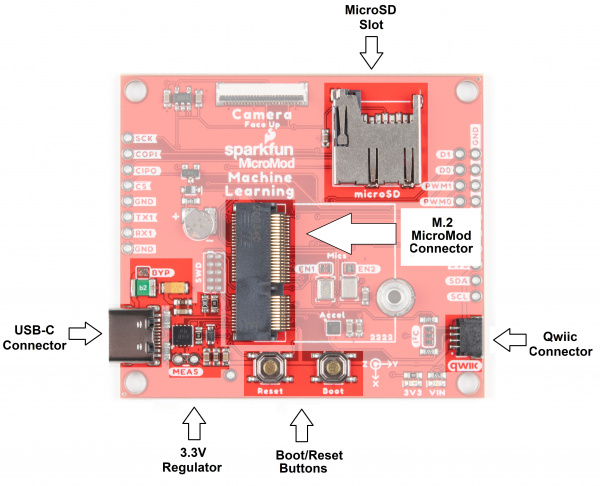

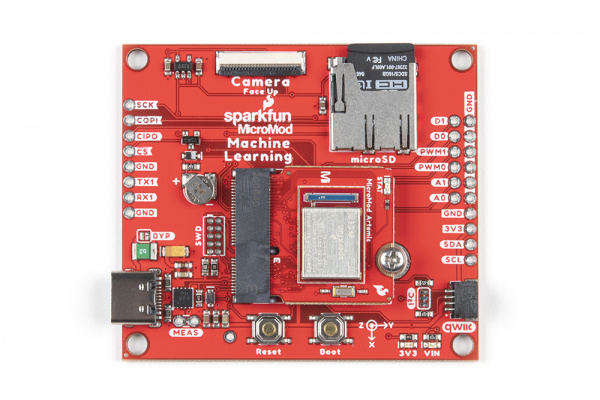

Most SparkFun MicroMod Carriers will have some common components and all MicroMod Carriers will have the keyed M.2 MicroMod Connector to plug your processor into. The photo and list below outline some of the components you can expect on most SparkFun MicroMod Carriers.

- M.2 MicroMod Connector - This special keyed M.2 connector lets you install your MicroMod Processor of choice on your Machine Learning Carrier Board.

- USB-C Connector - Connect to your computer to program your Processor and also can provide power to your MicroMod system.

- 3.3V Regulator - Provides a regulated 3.3V and sources up to 1A.

- Qwiic Connector - The standard Qwiic connector so you can add other Qwiic devices to your MicroMod system.

- Boot/Reset Buttons - Push buttons to enter Boot Mode on Processor boards and to Reset your MicroMod circuit.

- microSD Slot - Insert a microSD card for reading and writing data.

Machine Learning MicroMod Carrier Board Specific Components

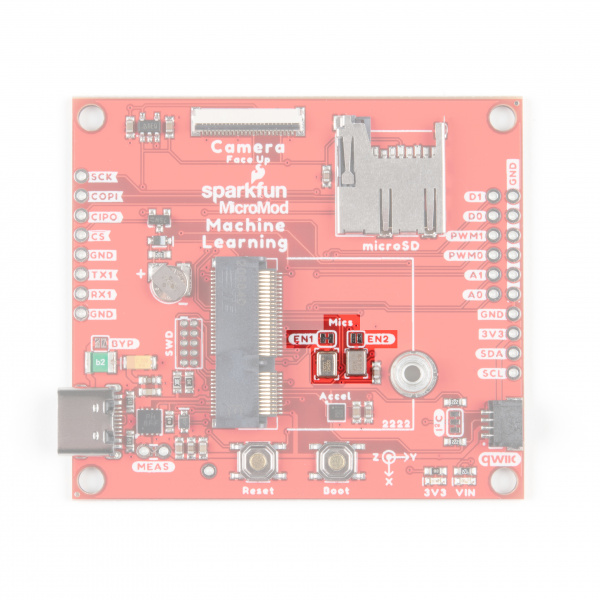

Digital MEMS Microphones

What's better than ONE microphone? TWO!

- Microphone 1 supports a PDM interface and is enabled by default. To disable this mic, cut the EN1 jumper. For more information on this microphone, refer to the datasheet here.

- Microphone 2 supports an I2S interface and is disabled by default. To enable EN2, solder the jumper pads to close the circuit. For more information on this microphone, refer to the datasheet here.

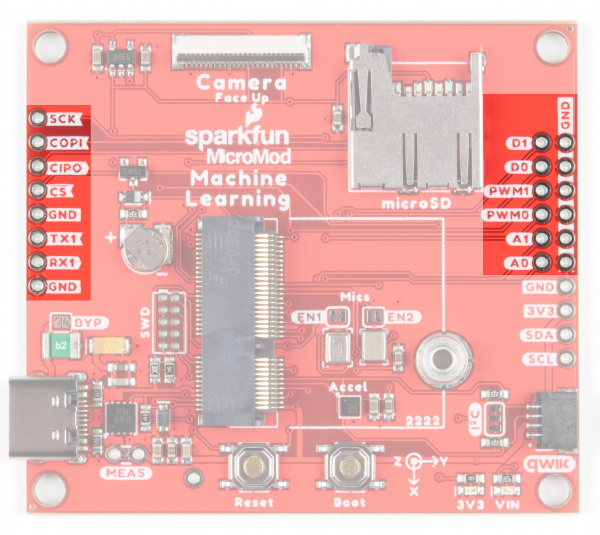

GPIO

Along the sides of the Machine Learning Carrier Board, we've broken out dedicated PTHs for UART, digital, analog, pulse width modulation, and SPI. You may also notice that we've included a ground rail on the right side of the board.

I2C Specific GPIO

Additionally, we've broken out the I2C SDA and SCL lines, with 3V3 and GND to complete your I2C functionality. These are primary I2C pins - they are connected to the Qwiic connector.

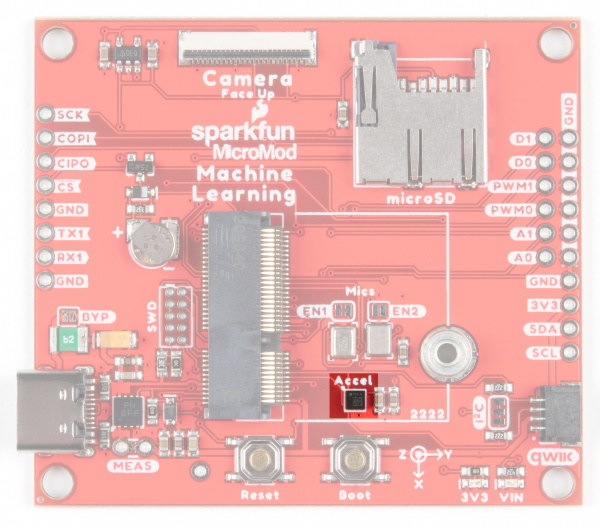

Accelerometer

The LIS2DH12 is an ultra-low-power, high performance, three-axis linear accelerometer belonging to the “femto” family with digital I2C/SPI serial interface standard output. If you need more detail on this little guy, refer to the Datasheet here.

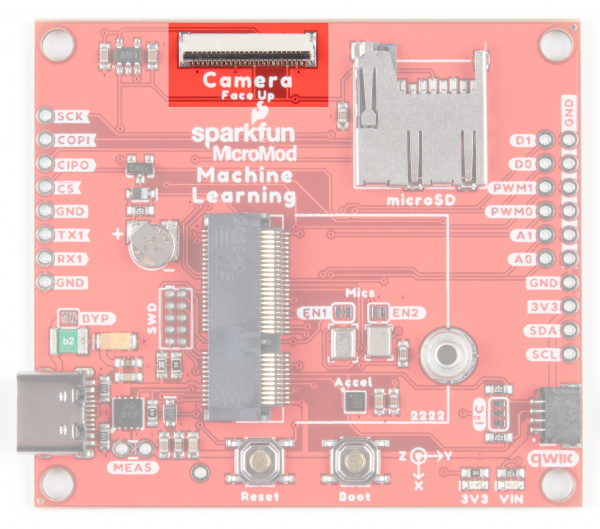

Camera Connector

With this 24 pin connector, you can add image recognition to your machine learning board by popping in the Himax CMOS Imaging Camera.

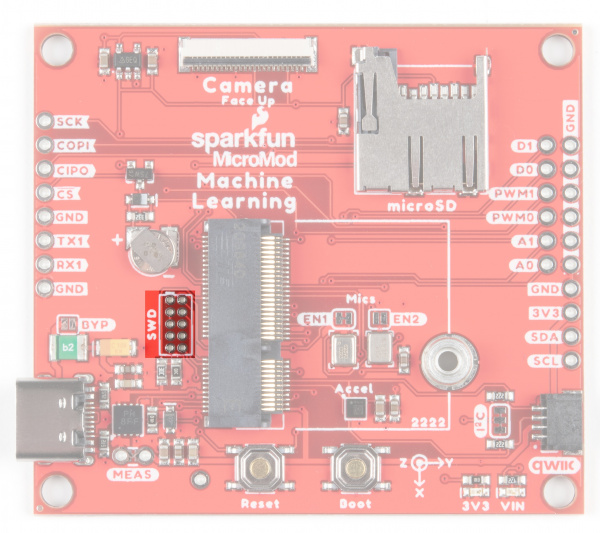

JTAG

An unpopulated JTAG footprint is available for more advanced users who need breakpoint level debugging. We recommend checking out our JTAG section for the compatible male header and a compatible JTAG programmer and debugger.

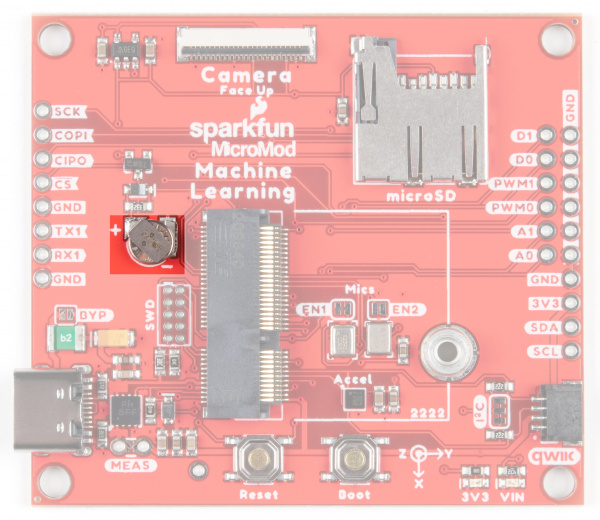

RTC Battery

We've included a 3V Lithium Rechargeable Battery as a backup power source.

Jumpers

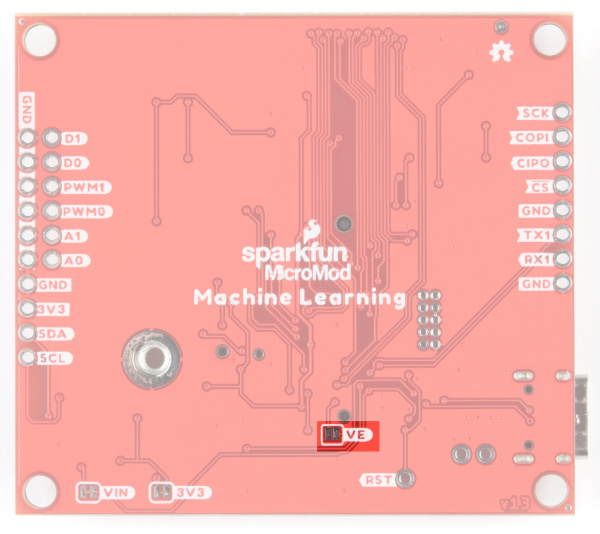

VE Jumper

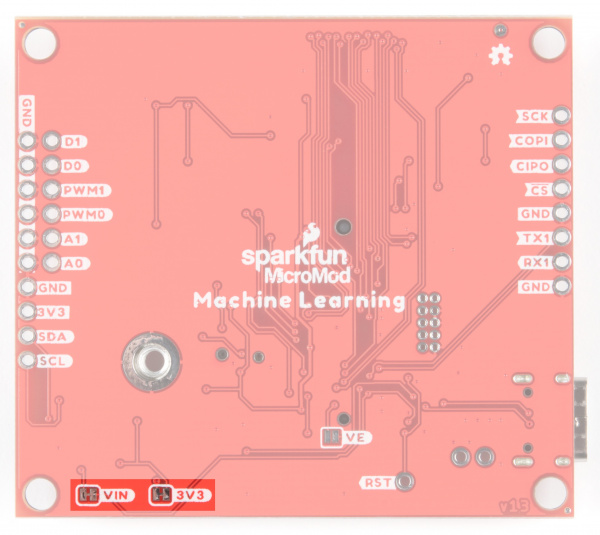

VIN and 3V3 Jumpers

Cutting these jumpers will disable the VIN and 3V3 LEDs on the front of the board.

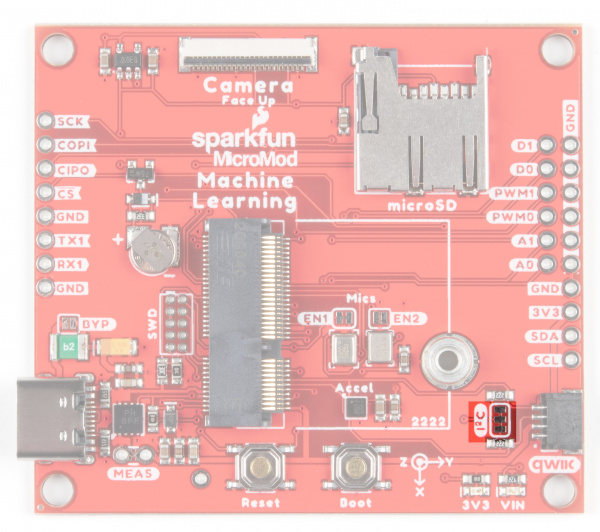

I2C Jumper

If you are daisy-chaining multiple Qwiic devices, you will want to cut this jumper; if multiple sensors are connected to the bus with the pull-up resistors enabled, the parallel equivalent resistance could create too strong of a pull-up for the bus to operate correctly. As a general rule of thumb, disable all but one pair of pull-up resistors if multiple devices are connected to the bus. To disable the pull up resistors, use an X-acto knife to cut the joint between the highlighted jumper pads.

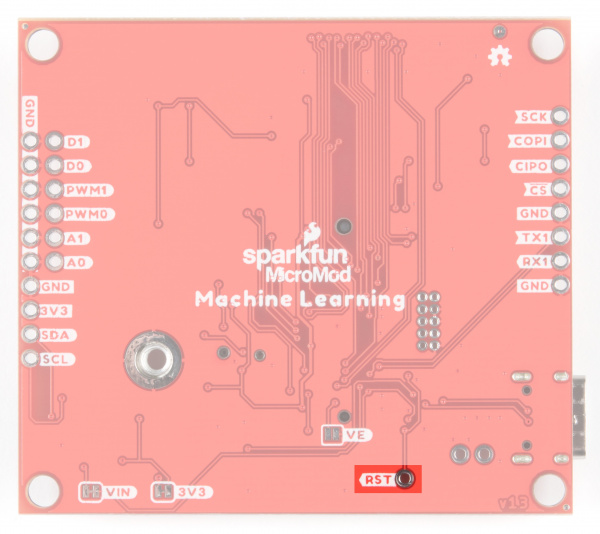

RESET PTH

Need an external reset button? These PTH allow you to tie in to the reset functionality.

Machine Learning MicroMod Carrier Pin Functionality

| AUDIO | UART | GPIO/BUS | I2C | SDIO | SPI0 | Dedicated |

| Function | Bottom Pin |

Top Pin |

Function | ||||||

|---|---|---|---|---|---|---|---|---|---|

| (Not Connected) | 75 | GND | |||||||

| 3.3V | 74 | 73 | G5 / BUS5 | ||||||

| RTC_3V_BATT | 72 | 71 | G6 / BUS6 | ||||||

| SPI_CS1# | SDIO_DATA3 (I/O) | 70 | 69 | G7 / BUS7 | |||||

| SDIO_DATA2 (I/O) | 68 | 67 | G8 | ||||||

| SDIO_DATA1 (I/O) | 66 | 65 | G9 | ADC_D- | CAM_HSYNC | ||||

| SPI_CIPO1 | SDIO_DATA0 (I/O) | 64 | 63 | G10 | ADC_D+ | CAM_VSYNC | |||

| SPI COPI1 | SDIO_CMD (I/O) | 62 | 61 | SPI_CIPO (I) | |||||

| SPI SCK1 | SDIO_SCK (O) | 60 | 59 | SPI_COPI (O) | LED_DAT | ||||

| AUD_MCLK (O) | 58 | 57 | SPI_SCK (O) | LED_CLK | |||||

| CAM_MCLK | PCM_OUT | I2S_OUT | AUD_OUT | 56 | 55 | SPI_CS# | |||

| CAM_PCLK | PCM_IN | I2S_IN | AUD_IN | 54 | 53 | I2C_SCL1 (I/O) | |||

| PDM_DATA | PCM_SYNC | I2S_WS | AUD_LRCLK | 52 | 51 | I2C_SDA1 (I/O) | |||

| PDM_CLK | PCM_CLK | I2S_SCK | AUD_BCLK | 50 | 49 | BATT_VIN / 3 (I - ADC) (0 to 3.3V) | |||

| G4 / BUS4 | 48 | 47 | PWM1 | ||||||

| G3 / BUS3 | 46 | 45 | GND | ||||||

| G2 / BUS2 | 44 | 43 | CAN_TX | ||||||

| G1 / BUS1 | 42 | 41 | CAN_RX | ||||||

| G0 / BUS0 | 40 | 39 | GND | ||||||

| A1 | 38 | 37 | USBHOST_D- | ||||||

| GND | 36 | 35 | USBHOST_D+ | ||||||

| A0 | 34 | 33 | GND | ||||||

| PWM0 | 32 | 31 | Module Key | ||||||

| Module Key | 30 | 29 | Module Key | ||||||

| Module Key | 28 | 27 | Module Key | ||||||

| Module Key | 26 | 25 | Module Key | ||||||

| Module Key | 24 | 23 | SWDIO | ||||||

| UART_TX2 (O) | 22 | 21 | SWDCK | ||||||

| UART_RX2 (I) | 20 | 19 | UART_RX1 (I) | ||||||

| CAM_TRIG | D1 | 18 | 17 | UART_TX1 (0) | |||||

| I2C_INT# | 16 | 15 | UART_CTS1 (I) | ||||||

| I2C_SCL (I/0) | 14 | 13 | UART_RTS1 (O) | ||||||

| I2C_SDA (I/0) | 12 | 11 | BOOT (I - Open Drain) | ||||||

| D0 | 10 | 9 | USB_VIN | ||||||

| SWO | G11 | 8 | 7 | GND | |||||

| RESET# (I - Open Drain) | 6 | 5 | USB_D- | ||||||

| 3.3V_EN | 4 | 3 | USB_D+ | ||||||

| 3.3V | 2 | 1 | GND | ||||||

| Function | Bottom Pin |

Top Pin |

Function | ||

|---|---|---|---|---|---|

| (Not Connected) | 75 | GND | |||

| 74 | 73 | CAMERA_D5 | |||

| RTC_3V | 72 | 71 | CAMERA_D6 | ||

| 70 | 69 | CAMERA_D7 | |||

| 66 | 65 | CAMERA_HSYNC | |||

| 64 | 63 | CAMERA_VSYNC | |||

| 62 | 61 | SPI_CIPO | |||

| 60 | 59 | SPI_COPI | |||

| 58 | 57 | SPI_SCK | |||

| CAMERA_MCLK | 56 | 55 | SPI_CS | ||

| CAMERA_PCLK | I2S_SD | 54 | 53 | ||

| PDM_DAT | I2S_WS | 52 | 51 | ||

| PDM_CLK | I2S_SCK | 50 | 49 | BATT_VIN/3 | |

| CAMERA_D4 | 48 | 47 | PWM1 | CAM_VDD | |

| CAMERA_D3 | 46 | 45 | |||

| CAMERA_D2 | 44 | 43 | |||

| CAMERA_D1 | 42 | 41 | |||

| CAMERA_D0 | 40 | 39 | |||

| A1 | 38 | 37 | |||

| A0 | 34 | 33 | |||

| PWM0 | 32 | 31 | |||

| 24 | 23 | SWDIO | |||

| 22 | 21 | SWDCK | |||

| 20 | 19 | RX1 | |||

| CAMERA_TRIG | D1 | 18 | 17 | TX1 | |

| CAMERA_INT | 16 | 15 | |||

| I2C_SCL | 14 | 13 | |||

| I2C_SDA | 12 | 11 | BOOT | ||

| HEADER_CS | D0 | 10 | 9 | VIN | |

| 8 | 7 | GND | |||

| RESET | 6 | 5 | USB_D- | ||

| 3.3V_EN | 4 | 3 | USB_D+ | ||

| 3.3V | 2 | 1 | GND | ||

| Signal Group | Signal | I/O | Description | Voltage | Power | 3.3V | I | 3.3V Source | 3.3V |

|---|---|---|---|---|

| GND | Return current path | 0V | ||

| USB_VIN | I | USB VIN compliant to USB 2.0 specification. Connect to pins on processor board that require 5V for USB functionality | 4.8-5.2V | |

| RTC_3V_BATT | I | 3V provided by external coin cell or mini battery. Max draw=100μA. Connect to pins maintaining an RTC during power loss. Can be left NC. | 3V | |

| 3.3V_EN | O | Controls the carrier board's main voltage regulator. Voltage above 1V will enable 3.3V power path. | 3.3V | |

| BATT_VIN/3 | I | Carrier board raw voltage over 3. 1/3 resistor divider is implemented on carrier board. Amplify the analog signal as needed for full 0-3.3V range | 3.3V | |

| Reset | Reset | I | Input to processor. Open drain with pullup on processor board. Pulling low resets processor. | 3.3V |

| Boot | I | Input to processor. Open drain with pullup on processor board. Pulling low puts processor into special boot mode. Can be left NC. | 3.3V | |

| USB | USB_D± | I/O | USB Data ±. Differential serial data interface compliant to USB 2.0 specification. If UART is required for programming, USB± must be routed to a USB-to-serial conversion IC on the processor board. | |

| USB Host | USBHOST_D± | I/O | For processors that support USB Host Mode. USB Data±. Differential serial data interface compliant to USB 2.0 specification. Can be left NC. | |

| CAN | CAN_RX | I | CAN Bus receive data. | 3.3V |

| CAN_TX | O | CAN Bus transmit data. | 3.3V | |

| UART | UART_RX1 | I | UART receive data. | 3.3V |

| UART_TX1 | O | UART transmit data. | 3.3V | |

| UART_RTS1 | O | UART ready to send. | 3.3V | |

| UART_CTS1 | I | UART clear to send. | 3.3V | |

| UART_RX2 | I | 2nd UART receive data. | 3.3V | |

| UART_TX2 | O | 2nd UART transmit data. | 3.3V | |

| I2C | I2C_SCL | I/O | I2C clock. Open drain with pullup on carrier board. | 3.3V |

| I2C_SDA | I/O | I2C data. Open drain with pullup on carrier board | 3.3V | |

| I2C_INT# | I | Interrupt notification from carrier board to processor. Open drain with pullup on carrier board. Active LOW | 3.3V | |

| I2C_SCL1 | I/O | 2nd I2C clock. Open drain with pullup on carrier board. | 3.3V | |

| I2C_SDA1 | I/O | 2nd I2C data. Open drain with pullup on carrier board. | 3.3V | |

| SPI | SPI_COPI | O | SPI Controller Output/Peripheral Input. | 3.3V |

| SPI_CIPO | I | SPI Controller Input/Peripheral Output. | 3.3V | |

| SPI_SCK | O | SPI Clock. | 3.3V | |

| SPI_CS# | O | SPI Chip Select. Active LOW. Can be routed to GPIO if hardware CS is unused. | 3.3V | |

| SPI/SDIO | SPI_SCK1/SDIO_CLK | O | 2nd SPI Clock. Secondary use is SDIO Clock. | 3.3V |

| SPI_COPI1/SDIO_CMD | I/O | 2nd SPI Controller Output/Peripheral Input. Secondary use is SDIO command interface. | 3.3V | |

| SPI_CIPO1/SDIO_DATA0 | I/O | 2nd SPI Peripheral Input/Controller Output. Secondary use is SDIO data exchange bit 0. | 3.3V | |

| SDIO_DATA1 | I/O | SDIO data exchange bit 1. | 3.3V | |

| SDIO_DATA2 | I/O | SDIO data exchange bit 2. | 3.3V | |

| SPI_CS1/SDIO_DATA3 | I/O | 2nd SPI Chip Select. Secondary use is SDIO data exchange bit 3. | 3.3V | |

| Audio | AUD_MCLK | O | Audio master clock. | 3.3V |

| AUD_OUT/PCM_OUT/I2S_OUT/CAM_MCLK | O | Audio data output. PCM synchronous data output. I2S serial data out. Camera master clock. | 3.3V | |

| AUD_IN/PCM_IN/I2S_IN/CAM_PCLK | I | Audio data input. PCM syncrhonous data input. I2S serial data in. Camera periphperal clock. | 3.3V | |

| AUD_LRCLK/PCM_SYNC/I2S_WS/PDM_DATA | I/O | Audio left/right clock. PCM syncrhonous data SYNC. I2S word select. PDM data. | 3.3V | |

| AUD_BCLK/PCM_CLK/I2S_CLK/PDM_CLK | O | Audio bit clock. PCM clock. I2S continuous serial clock. PDM clock. | 3.3V | |

| SWD | SWDIO | I/O | Serial Wire Debug I/O. Connect if processor board supports SWD. Can be left NC. | 3.3V |

| SWDCK | I | Serial Wire Debug clock. Connect if processor board supports SWD. Can be left NC. | 3.3V | |

| ADC | A0 | I | Analog to digital converter 0. Amplify the analog signal as needed to enable full 0-3.3V range. | 3.3V |

| A1 | I | Analog to digital converter 1. Amplify the analog signal as needed to enable full 0-3.3V range. | 3.3V | |

| PWM | PWM0 | O | Pulse width modulated output 0. | 3.3V |

| PWM1 | O | Pulse width modulated output 1. | 3.3V | |

| Digital | D0 | I/O | General digital input/output pin. | 3.3V |

| D1/CAM_TRIG | I/O | General digital input/output pin. Camera trigger. | 3.3V | |

| General/Bus | G0/BUS0 | I/O | General purpose pins. Any unused processor pins should be assigned to Gx with ADC + PWM capable pins given priority (0, 1, 2, etc.) positions. The intent is to guarantee PWM, ADC and Digital Pin functionality on respective ADC/PWM/Digital pins. Gx pins do not guarantee ADC/PWM function. Alternative use is pins can support a fast read/write 8-bit or 4-bit wide bus. | 3.3V |

| G1/BUS1 | I/O | 3.3V | ||

| G2/BUS2 | I/O | 3.3V | ||

| G3/BUS3 | I/O | 3.3V | ||

| G4/BUS4 | I/O | 3.3V | ||

| G5/BUS5 | I/O | 3.3V | ||

| G6/BUS6 | I/O | 3.3V | ||

| G7/BUS7 | I/O | 3.3V | ||

| G8 | I/O | General purpose pin | 3.3V | |

| G9/ADC_D-/CAM_HSYNC | I/O | Differential ADC input if available. Camera horizontal sync. | 3.3V | |

| G10/ADC_D+/CAM_VSYNC | I/O | Differential ADC input if available. Camera vertical sync. | 3.3V | |

| G11/SWO | I/O | General purpose pin. Serial Wire Output | 3.3V |

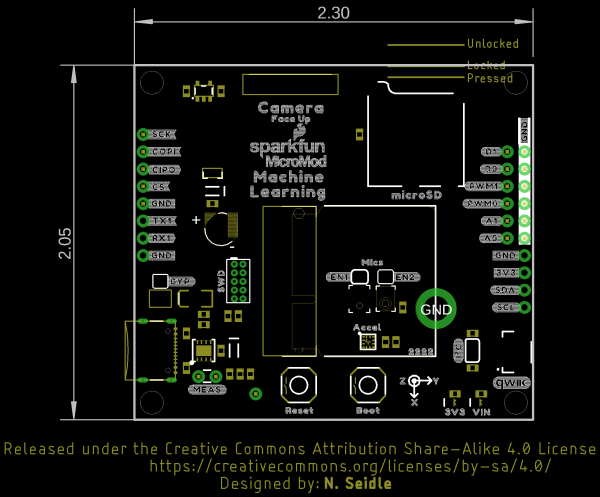

Board Dimensions

The Machine learning Carrier Board measures 2.3 inches by 2.05 inches.

Hardware Hookup

To get started with the Machine Learning Carrier Board, you'll need a compatible processor board. Here we are using the MicroMod Artemis Processor Board.

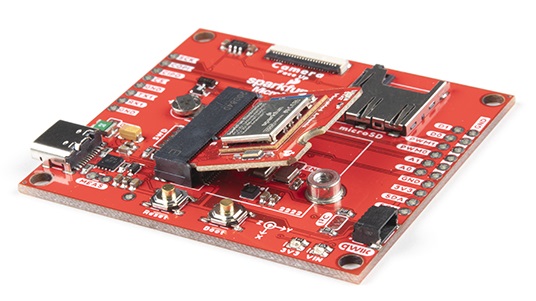

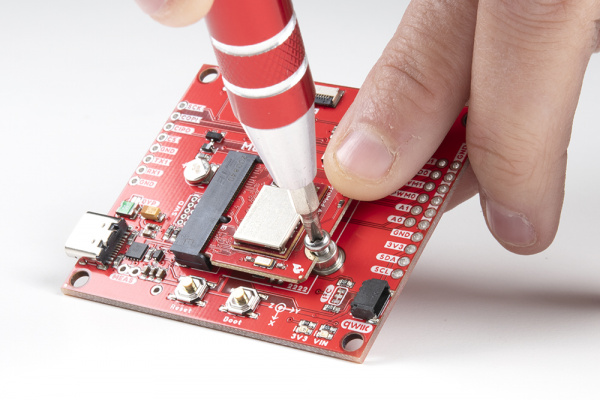

Align the top key of the MicroMod Artemis Processor Board to the screw terminal of the Machine Learning Carrier Board and angle the board into the socket. Insert the board at an angle into the M.2 connector.

The Processor Board will stick up at an angle, as seen here:

Once the board is in the socket, gently hold the MicroMod Processor Board down and tighten the screw with a Phillip's head.

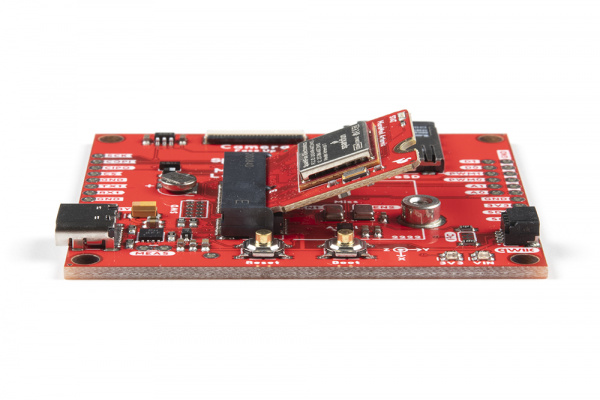

Once the board is secure, your assembled MicroMod system should look similar to the image below!

Connecting Everything Up

With your processor inserted and secured it's time to connect your carrier board to your computer using the USB-C connector on the Carrier. Depending on which carrier you choose and which drivers you already have installed, you may need to install drivers.

For this particular tutorial, we are using the MicroMod Artemis Processor Board. Board definitions for this processor board can be found in the Software Setup and Programming section of the MicroMod Artemis Processor Board Hookup Guide.

If you are using a different processor board, go to our MicroMod Processor Boards landing page, find your processor board, and head on over to that tutorial for help installing your board definition.

Example 1: Blink

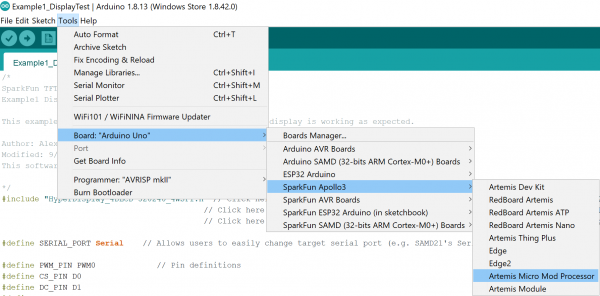

To get started uploading code and working with your Machine Learning Carrier Board, make sure you have the MicroMod Artemis board definition selected under your Tools > Board menu (or whatever processor you've chosen to use).

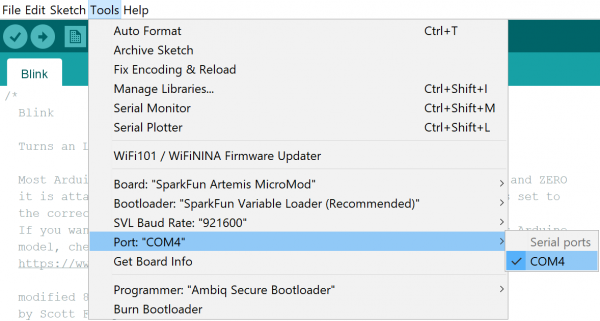

Then select your serial port under the Tools > Port menu.

Loading Blink

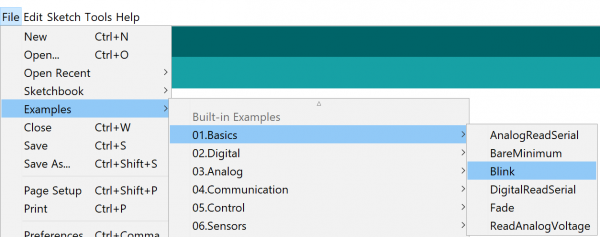

Let's start with something basic - let's blink an LED. Go to File->Examples->01.Basics->Blink.

With everything setup correctly, upload the code! Once the code finishes transferring, you should see the STAT LED on the Artemis Processor Board begin to blink!

Look at all the blinks!

Example 2: Accelerometer

SparkFun has written a library to work with the LIS2DH12 Accelerometer that's included on this board. You can obtain this library through the Arduino Library Manager by searching for "LIS2DH12". Find the one written by SparkFun Electronics and install the latest version. If you prefer downloading libraries manually, you can grab them from the GitHub Repository. We've linked the datasheet for the accelerometer in the Resources and Going Further section, but if you'd like it handy, you can also refer to it here.

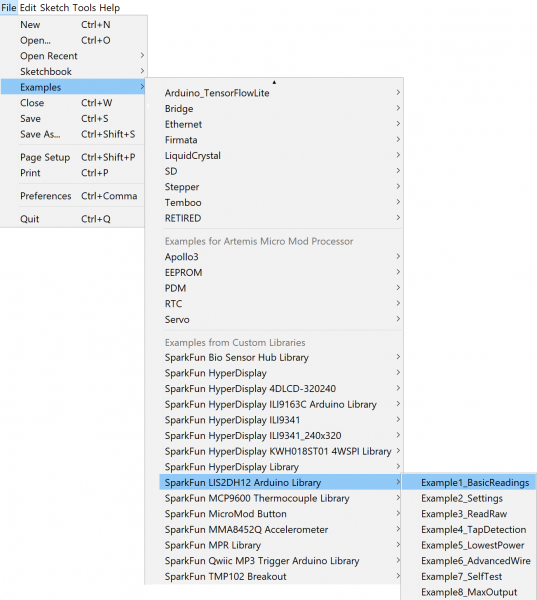

With your library installed, navigate to the examples located under File->Examples->SparkFun LIS2DH12 Arduino Library. Let's load up Example1_BasicReadings to get you started.

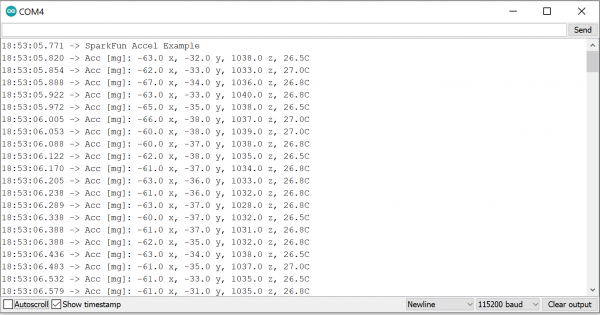

Making sure you have the correct board and port selected, go ahead and upload your code. Once the code finishes transferring, open the serial monitor and set the baud rate to 115200. You should see x y and z locations flying by, telling you the directions the accelerometer is reading!

Troubleshooting

If you need technical assistance and more information on a product that is not working as you expected, we recommend heading on over to the SparkFun Technical Assistance page for some initial troubleshooting.

If you don't find what you need there, the SparkFun Forums: MicroMod are a great place to find and ask for help. If this is your first visit, you'll need to create a Forum Account to search product forums and post questions.

Resources and Going Further

Want more information on the SparkFun Machine Learning Carrier Board? Check out these links!

- Schematic (PDF)

- Eagle Files (ZIP)

- GitHub Hardware Repo

- Accelerometer Datasheet

- Default PDM Microphone Datasheet

- Microphone 2 I2S Datasheet

MicroMod Documentation:

Looking for some project inspiration using your Machine Learning Carrier Board? The tutorials below can help you get started!