My students had a dance performance with the theme "Night at the Movies." I decided to choose a story based on "The Diamond" episode from the old Mission: Impossible television show. To make it fun for the kids and convey the story better to the audience, I decided to build an interactive 3D printed diamond. In this tutorial, you will learn how to 3D print a model and embed electronics in a theatrical prop.

To follow along with this project tutorial, you will need the following materials. You may not need everything though depending on what you have. Add it to your cart, read through the guide, and adjust the cart as necessary.

You will need a soldering tools, a 3D printer, and a hobby knife.

You will also need:

If you aren't familiar with the following concepts, we recommend checking out these tutorials before continuing.

I do not have much experience with 3D printing and modeling complex shapes. Luckily, there were a few models of diamonds listed online that I found to save on time. After browsing Thingiverse, the model that I found appealing was "Oopee's" diamond lampshade. Head over to the thing and download to print the model of your size.

Printing a medium size diamond was sufficient and easy to see on stage as a prop. Caution is advised for printing large scale models due to time and material used.

To start, I printed a small scale version of the diamond lampshade in Cura to see how it would look. The diamond on the bottom left shows the first print of the diamond against the larger prints. Satisfied with the small print. I decided to go bigger!

I decided to go big and start printing the diamond. Unfortunately, I ran into an issue once the print started. The 3D printer's extruder kept getting clogged causing the print to fail. I tried using a needle to clean the nozzle and manually feeding more material in the extruder. This fixed the problem temporarily but the issue kept coming up.

Doing a search online and inspecting the setup, there were a few possible reasons why this might have been happening:

A clogged extruder seemed to be a plausible explanation of what was going on. Checking in with someone more knowledgeable about 3D printing at SparkFun, I headed over to a mechanical engineer for advice and showed him a few of the stripped filaments as shown below.

He was able to confirm my assumption. With the technical support's 3D printer being used communally, he explained that the clogged extruder was probably due to either:

So how would you fix the clogged extruder? An acetone bath! This was a last resort considering my previous efforts had failed. After removing the tool head from the Lulzbot 3D printer, we carefully removed the hot end's nozzle using some pliers. And by careful, we had to avoid breaking the thermistor attached to the hot end. Once removed, a glass jar was filled just enough to submerge the nozzle tip in acetone and cleaned with a Q-tip over the course of 2 days.

While the nozzle was being cleaned, our mechanical engineer was kind enough to allow me to use the mechanical engineering's 3D printer. Off I went to print the big diamond. However, I ran into yet another problem. I did not have enough material! I was too ambitious and did not keep track of the amount of material I had available. 30 hours into the print, I ran out of material as you can see from the image below. While the print failed, I decided to recycle the failed print by making it into a diamond holder.

Success! On my 10th attempt with a replenished supply of clear filament, I was able to successfully print a diamond. I found a happy medium of printing a diamond. After learning some lessons from the failed prints, I reduced the amount of material used between the walls and reduced the size of the model to a smaller size. Confident in the print, I printed another diamond slightly larger.

Check out the circuit diagram below to see how everything is connected.

During rehearsals, the prop was initially powered by a 12V wall adapter. It was bulky and not ideal for quick set changes between pieces. Therefore, I decided make it portable using a 9V battery to power the LED strip and controller.

After testing, I noticed that the 9V battery connected to the Arduino's microcontroller not sufficient enough for the LED strip. The LED strip was not bright enough or would display the wrong color.To remedy this, a second 9V battery was attached to the LED strip. Ground was connected to both batteries for reference.

Since the non-addressable RGB LED strip operate at a higher voltage, a transistor was needed to prevent damage to the microcontroller. A pull-down resistor was also needed so that the Arduino would not have a floating pin. Each color required one n-channel mosfet and one 10kΩ resistor.

Initial testing included momentary push buttons with code utilizing the pull-up resistors on the digital pins. One button (connected to pin 2 with a white wire) was used to adjust the color while the other (connected to pin 3 with a yellow wire) was used to change the pattern. The buttons were left on the board to troubleshoot connections.

Eventually, the button to trigger the color was replaced with a capacitive touch sensor and external electrodes. The Arduino had issues reading the capacitive touch sensor's "OUT" pin by itself so a small npn transistor was added to trigger the button press. A resistor was used as current limiting resistor to the BJT's base pin.

With some non-addressable RGB LED strips left over from a previous project, I decided to cut down the remaining strip and solder male jumper wire with male pins. To make it easier, you could use a 4-pin polarized connector and a 1M sealed strip. For the scope of this tutorial, we will be modifying the LED strip and using male jumper wires.

Cut the LED strip at the center of the exposed pads using a diagonal cutter. The dot and dashed line in the image below is where you will need to perform the cut. Make sure to remove part of the silicone tube in order to be able to access the LED strip's pads.

Cut half of the 12" premium jumper wires and strip the insulation. Then solder the wires to each of the LED strip's pads.

The connection to the pads needed to be secure so I decided to braid the wires together to manage the connections. I was inspired by McCall’s tutorial when completing projects. To braid your wires, twist a pair of wires in a counterclockwise pattern between your index finger and thumb using both hands. I decided to start with the green and red wires.

Twist the other pair of wires in a counterclockwise pattern.

Twist the pairs of wires in a clockwise pattern.

If you were using water soluble flux, clean the solder joints with de-ionized water and a toothbrush. Dry the LED strips thoroughly using compressed air. Luckily, SparkFun has a PCB cleaning room. As an alternative, you could use water from the sink and towels.

Once dry, test the LED strips to make the colors matched and the wires are connected to its respective pads. I decided to use a benchtop power supply set to output about 9V to verify the connection.

Add hot glue to the terminals to secure the wires further.

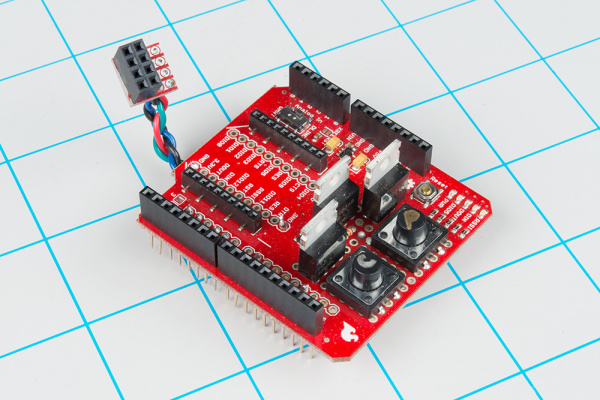

I decided to use a spare XBee shield for the LED strip's adapter. This also gave me the option of making the circuit wireless if I were to use this in a future project. For the scope of this tutorial, we will be using the XBee shield. You could use a protoshield for more space.

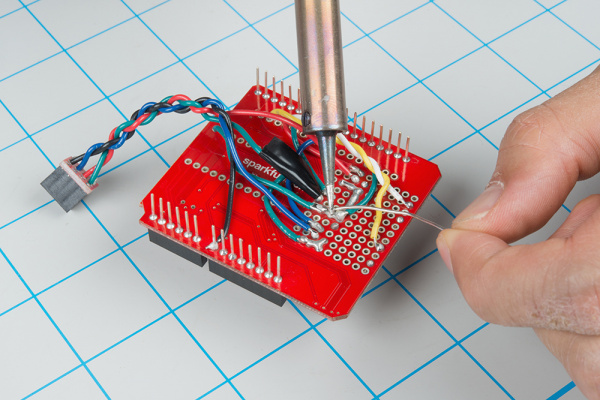

To make the adapter, solder the three n-channel mosfets, three 10kΩ resistors, and two buttons to the prototyping area based on the Fritzing circuit shown earlier. The two solder jumpers were that were connected to the logic level converters and the associated pins were removed. With very little room left, wires were extended out of the bottom of the shield using female headers and prototyping board. Again, the board was clean and tested before moving further.

|

|

Solder the AT42QT1011 capacitive touch breakout with the longer ends facing the component side. At this point, there was not a lot of room left on the board. Therefore, a mini-breadboard, jumper wires, npn transistor, and 330Ω resistor was need to connect it to the rest of the circuit for initial testing.

Note: This example assumes you are using the latest version of the Arduino IDE on your desktop. If this is your first time using Arduino, please review our tutorial on installing the Arduino IDE.

Download the example code to read the capacitive touch sensor and trigger the LED strip's color. Just make sure to select the correct COM port and upload with the correct board definition when uploading.

To secure the electronics, a cardboard enclosure was made to house the electronics. I considered using just the diamond holder but the space was limited. Grab a cardboard box and cut a hole in the shape of the holder's bottom.

Placed the electronics in the enclosure and secure using electrical tape. This would also be a good time to tape the diamond holder down.

Cut an additional hole for the wires leading to the copper tape electrode.

Now that we have an enclosure, the finishing touches can be added to the prop. Cut out a strip of 2" copper tape and solder two pieces of wire to it. Make sure the wire is long enough to extend the capacitive touch sensor's pin labeled "PAD" to the circuit's enclosure and to the top of the diamond holder. Solder the other end of the wire to the capacitive touch sensor. Remove the backing and stick the copper tape to the inside wall of the enclosure.

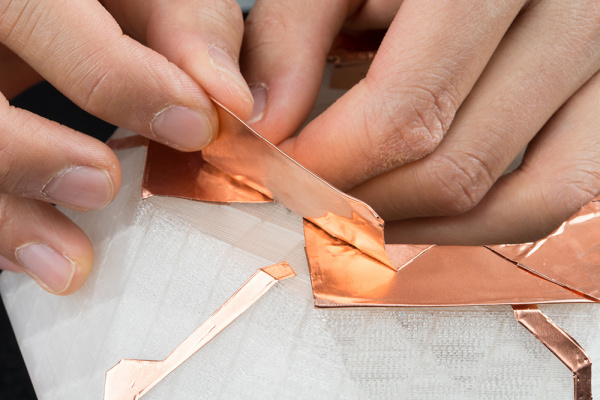

To distinguish the diamond and the holder, copper tape was also added to the top of the holder. Cut out a another piece of the 2" copper tape. Then cut into the tape to match the inside of the holder's edge.

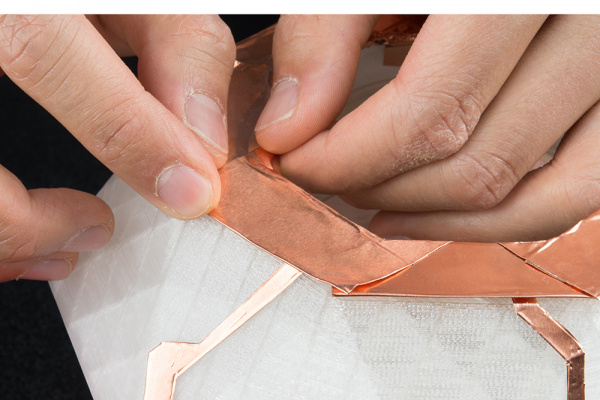

Remove the backing and attach the trapezoid section of the tape to the holder. Then fold the rest of the copper tape in half so that the conductive top side is able to conduct on the top and bottom. Then lay the copper tape flat. Repeat for each edge of the diamond until you have one side left.

|

|

With one side left, solder the second wire to extend the capacitive touch sensor's pad to the trapezoid section. Pull the wire up through the enclosure and holder. Attach the copper tape to the final edge.

To blend the copper tape on the holder, I decided to add copper tape on the sides of a diamond. This is an optional step but it helped to distinguish the diamond's holder from the diamond itself. I decided to use the RedBoard's traces as a guide. Using the board layout files (with layers 16, 22, and 51 turned off), I was able to print out the top layer out. The angles from the traces helped as a guide when manually cutting. Manually cutting holes for vias was considered but was left out of the design.

Print out the file and cut out holes loosely based on the RedBoard's layout to make a stencil. Make sure that the traces are no less than 1/4 of an inch. Trace the outline with a semi-sharp tip. I used a multimeter prob tip to create a loose outline of the a few different traces.

Carefully cut with hobby knife and ruler on a cutting board.

Using a small piece of 5mm conductive adhesive tape, I made a loop with the conductive adhesive on the outside and stuck it between each layer of copper to ensure that each piece was conducting.

Here's a demo of how quickly I was able to power up and test the prop before the performance.

There were a few methods of triggering the LED's color. My students were instructed to touch the top of the holder to trigger the red color in the middle of the piece. However, there were several other ways to change the color in case anything happened. Here's a quick demo.

The instructions were simple enough for my students to understand and the circuit turned out well for the rehearsals.

|

|

When it came time for the show, I had my handy multimeter, scissors, electrical tape, and backup 9V batteries just in case I needed to troubleshoot. However, the only issue that I ran into was not caused by the prop. The stage manager indicated that the fog from a fog machine could cause the fire alarm to go off. As an alternative, I found that dry ice and water seemed to work as a replacement. Here's a picture of the team after they went on!

There’s always room for improvement. After the project was completed, I realized that the prop could improved. Below are a list of possible upgrades and improvements that could be implemented for future builds.

For more information related to the project, check out the resources below:

Need some inspiration for your next project? Check out some of these related tutorials:

Or check out some of these blog posts for ideas:

learn.sparkfun.com | CC BY-SA 3.0 | SparkFun Electronics | Niwot, Colorado