How to Solder: Through-Hole Soldering

Contributors:

Joel_E_B

Joel_E_B

Soldering Your First Component

Let's put all these tools into action. This first video will go over the basics of soldering your first component -- headers!

Check out the Vimeo version here.

Recap

It's really that easy! Follow Dave's simple rules to make every solder connection a good one.

- Be cautious when handling hot irons

- Use third hands or vices to hold boards while you solder

- Set your iron at a good medium heat (325-375 degrees C)

- If you see smoke coming from your solder, turn down the heat

- Tin your tip with solder before each connection to help prep the joint

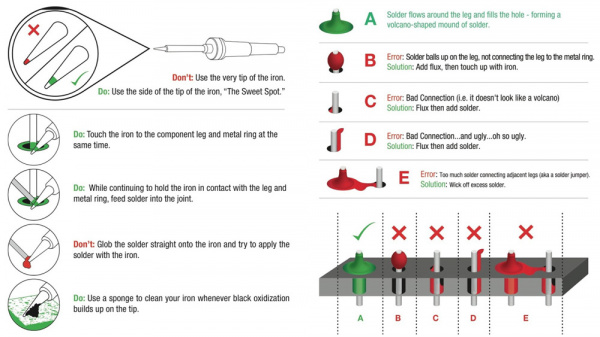

- Use the side of the tip (aka the sweet spot), not the very tip of the iron

- Heat both the pad and the part you want to solder evenly and at the same time

- Pull the solder away, then the iron

- A good solder joint should look like a volcano or Hersey kiss, not a ball or clump

We've also put together this digram to help you better understand what makes a good solder joint.

Click for a larger image.

When you are finished, tin the tip to increase its life before turning your soldering iron off.