Constant Innovation in Quality Control

Cap-Sense Buttons

Pictured above is our classic small momentary button. A simple mechanical switch is a great way for the tech to engage a test. We used this button on hundreds of testbeds. There are still hundreds on the production floor today. However, we found that after a few months on the floor (especially with our more popular products that may see 1000s of presses a day), the button would stop working 100% of the time. We found ourselves replacing quite a few buttons each week.

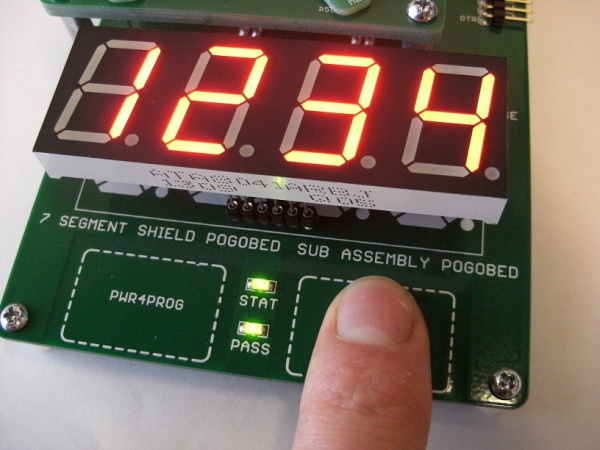

In order to solve this problem once and for all, we moved to a non-mechanical approach: capacitive touch. With this new approach, there is no mechanical connection to wear out, and we never see these fail on the floor. Below is a picture of our testbed for the OpenSegment Shield. You can see the two capsense buttons that engage the different portions of the test.

If you're new to capacitive touch, check out this great tutorial on Arduino here . This is the same library and hardware technique that we use on all of our testbeds these days.

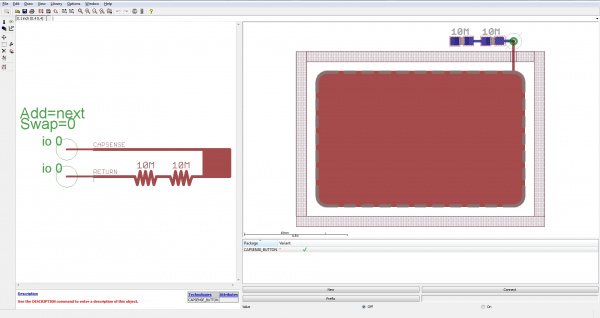

We have also created a special Eagle device that includes a few nice features in the package to speed up design work. It has a good sized metal pad to use as the sense area. It includes no tstop on the pad to protect from finger oils and oxidization. It also has a box of trestrict built into the package to keep the ground pour away. It has a dotted line on the silk to designate the touch area of the button. And lastly, the resistor is built into the package, so this makes it really easy to drop into a design.

At first, we thought that for the more simple testbeds it seemed a bit over-kill to include a micro just to engage a button. But we are finding now that 30 minutes invested in the design and assembly of a testbed is well worth the effort if it can ensure that the testbed will live on for years without the need for repairs. In most cases with QC related hardware, we invest our time and efforts to find the more permanent fix.