RETIRED - Load Cell Amplifier HX711 Breakout Hookup Guide

This Tutorial is Retired!

This tutorial covers concepts or technologies that are no longer current. It's still here for you to read and enjoy, but may not be as useful as our newest tutorials.

View the updated tutorial: Load Cell Amplifier HX711 Breakout Hookup Guide

Getting Started

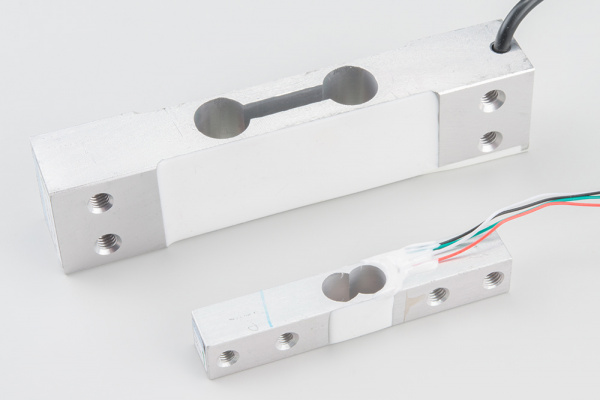

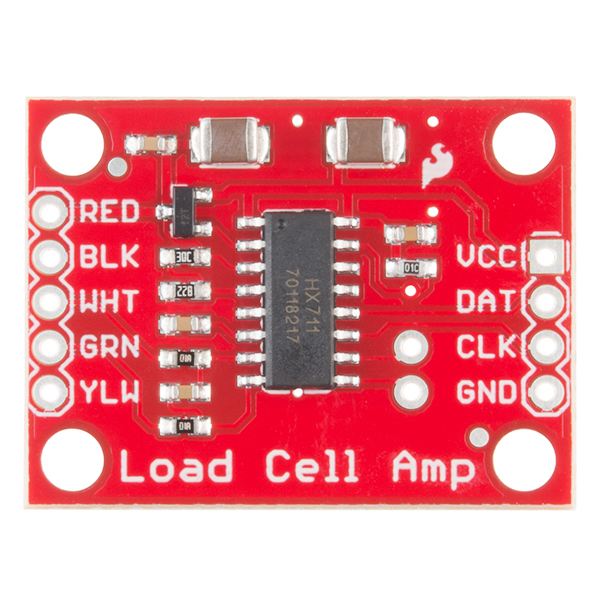

The HX711 load cell amplifier is used to get measurable data out from a load cell and strain gauge. This Hookup Guide will show you how to get started with this amplifier using some of the various load cells we carry at SparkFun.

What You Will Need:

For this simple hook up guide we will just be hooking up a load cell with the HX711 amplifier, and showing how you would hook up four load cells with a combinator board and the HX711 amplifier. To follow along, you'll need:

- SparkFun Load Cell Amplifier - HX711

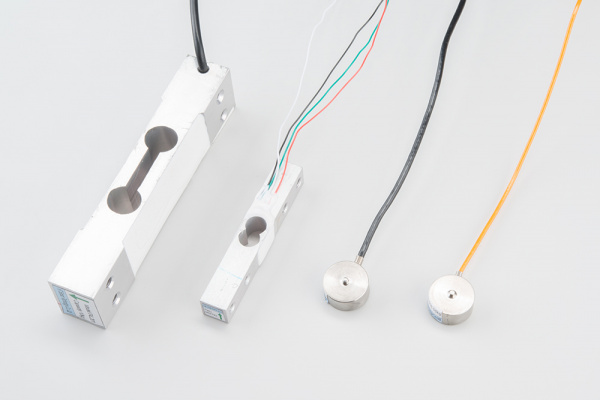

- Any Strain Gauge Based Load Cell:

Retired

Load Cell - 10kg, Wide Bar (TAL201)

SEN-13330

If you are planning on using load sensors1 you will need to obtain or purchase four units. We recommend our Combinator Board to make it easy to turn the four strain gauges into a wheatstone bridge type load cell. (Single strain gauge load cells only have three wires instead of four.)

- (Optional) Combinator Board

Suggested Reading

If you aren't familiar with the following concepts, we recommend reviewing them before beginning to work with the HX711 Load Cell Amplifier Board.

- Load Cell Basics

- Getting Started with Load Cells

- Installing the Arduino IDE

- How to Power Your Project

- Battery Technologies

- How to Solder

1. [Strain gauges are two wired organized metal foil or wires that are set up in such a way that the resistance changes when it is compressed or stretched. When a strain gauge is placed on something (usually metallic in nature) its resistance changes based on the stress experienced by that something. When a single strain gauge is hooked up to a metallic cell, we are calling that a load sensors, which have three output wires. Load cells usually has four strain gauges hooked up in a wheatstone bridge formation, which have four output wires. For more information on load cells, strain gauges, and wheatstone bridges see our tutorial.]↩

Load Cell Set Up

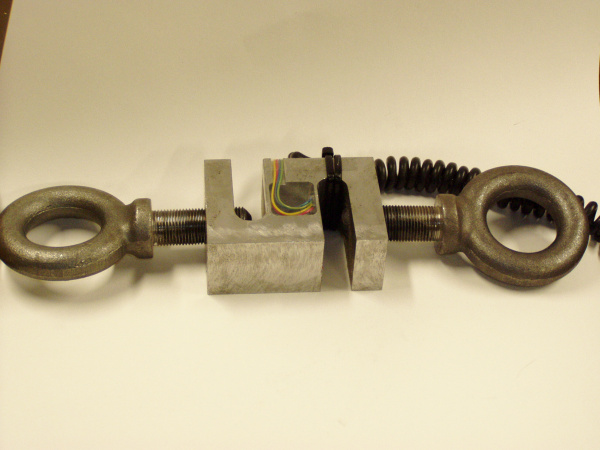

Depending on the type of load cell you are using, the configuration of how it should be hooked up to plates or surfaces will change. Below are a few different types of setups.

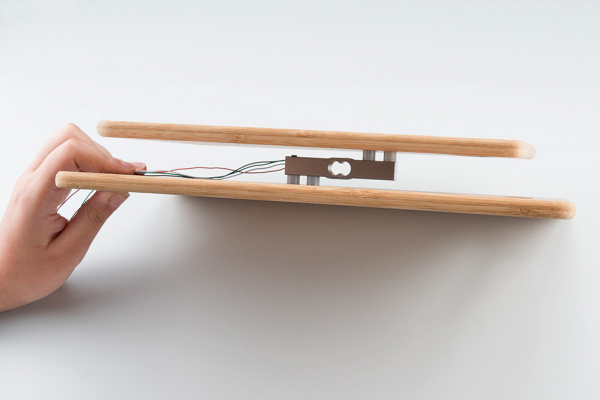

Usually with larger, non-push button bar load cells you will want to hook up the load cell between two plates in a "Z" shape, with fitting screws and spacers so that the strain can be correctly measured as shown below:

Note that only one side of the load cell is screwed into each board. This provides a moment of force, or torque, on the strain gauge rather than just compression force, which is easier to measure and much more accurate.

For smaller, push-button or disc load cells, you will want to make sure to screw in the disc to a bottom plate (or surface you are measuring force against), and center the beam, plate, or whatever else you are wishing to measure the force of onto the "button" on the top. Usually another plate with a hole is used to make sure whatever you are measuring is hitting the same spot on the load cell each time, but it is not necessary.

Make sure to read the datasheet for the load cell you are using and get the correct screws to fit into it.

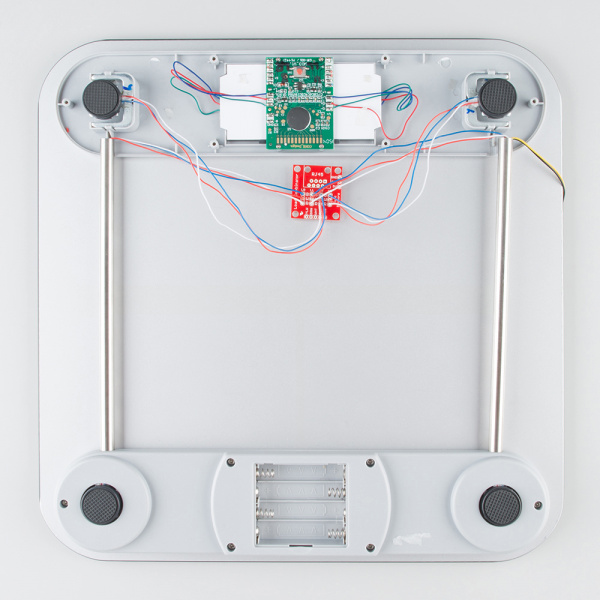

- Note: If you are hooking together four of the SparkFun Load Sensors using the Combinator board, you should position the four load sensors equidistant from each other, just like the bathroom scales shown in this tutorial.

Load cell measurements can be off by +/- 5% due to a range of things including temperature, creep, vibration, drift, and other electrical and mechanical interferences. Before you install your scale, take a moment and design your system to allow for easy calibration or be able to adjust the code parameters to account for these variations.

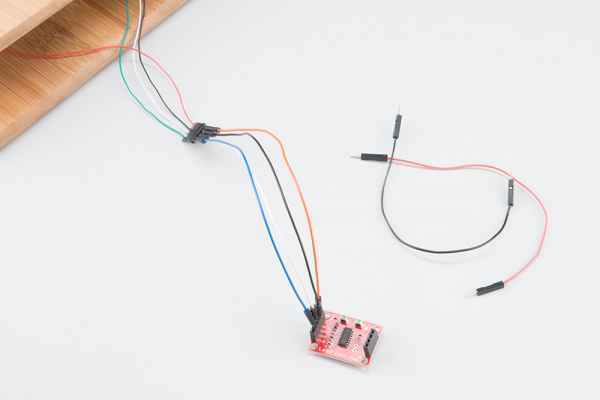

Hardware Hookup

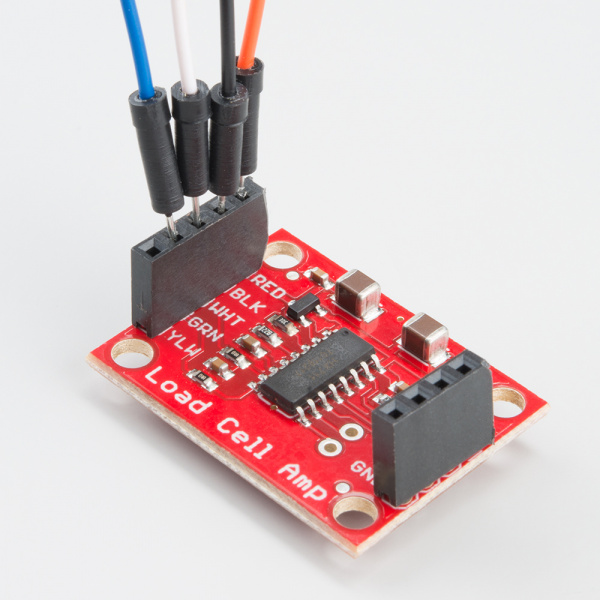

The HX711 Load Cell Amplifier accepts five wires from the load cell. These pins are labeled with colors; RED, BLK, WHT, GRN, and YLW. These colors correspond to the conventional color coding of load cells, where red, black, green and white wires come from the strain gauge on the load cell and yellow is an optional ground wire that is not hooked up to the strain gauge but is there to ground any small outside EMI (electromagnetic interference). Sometimes instead of a yellow wire there is a larger black wire, foil, or loose wires to shield the signal wires to lessen EMI.

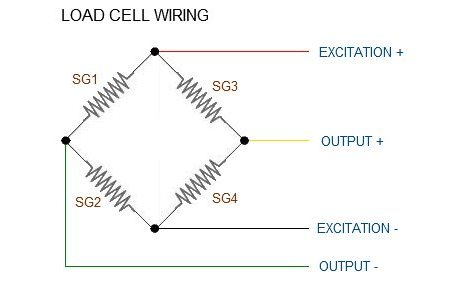

In General, each load cell has four strain gauges that are hooked up in a wheatstone bridge formation as shown above.

The four wires coming out from the wheatstone bridge on the load cell are usually:

- Excitation+ (E+) or VCC is red

- Excitation- (E-) or ground is black.

- Output+ (O+), Signal+ (S+)+ or Amplifier+ (A+) is white

- O-, S-, or A- is green or blue

Some load cells might have slight variations in color coding such as blue instead of green or yellow instead of black or white if there are only four wires (meaning no wire used as an EMI buffer). You might have to infer a little from the colors that you have, but in general you will usually see these colors.

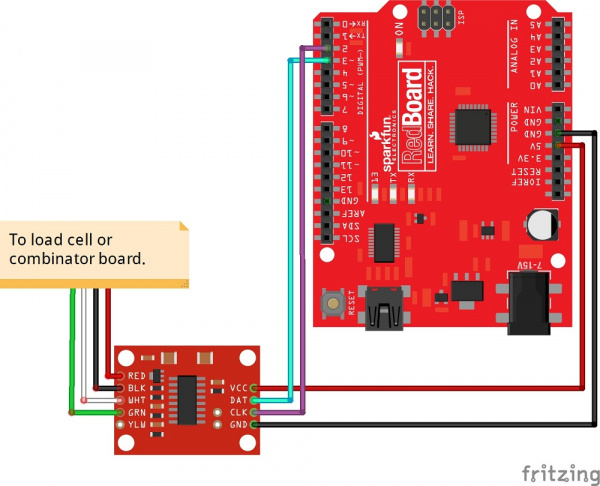

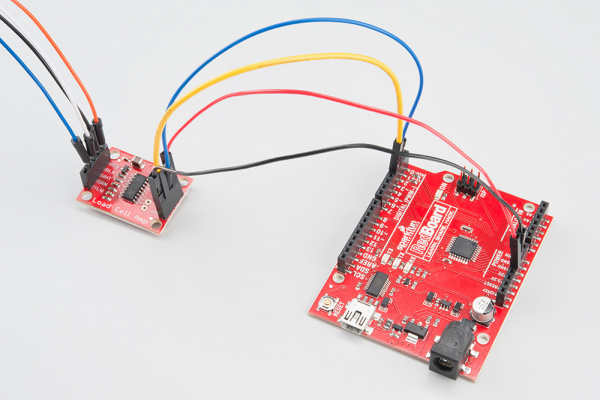

Once the load cell is is hooked up to the amplifier, you can hook up VCC, DAT, CLK, and GND to a micro controller such as a RedBoard or Arduino board.

The example code has DAT and CLK **hooked up to **pin 3 and 2 respectively, but this is easily changed in the code. Any GPIO pin will work for either. Then VCC and GND just need to be hooked up to 2.7V-5V and ground respectively on your microcontroller.

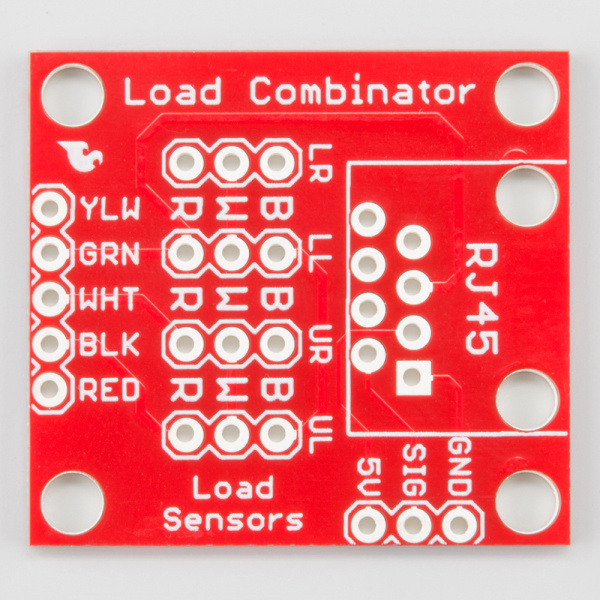

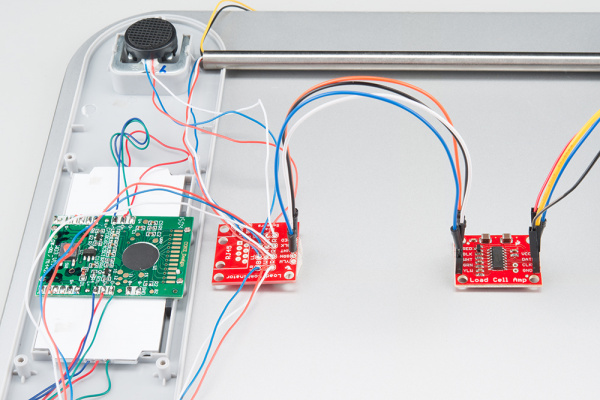

Now, if you would like to set up four single strain gauge load cells with our combinator board and the amplifier, it works in a similar way, hooking up the red, black, and white wires from four different single strain gauge load cells and then hooking up the five RED, BLK, WHT, GRN, and YLW pins from the combinator board to the HX711.

The combinator board also has room for an 8 pin RJ45 socket, which can be used to connect your project via Ethernet cables for long distance applications.

Another nice thing about our combinator board is that most home scales use four single strain gauge load cells, so this is a handy board for hacking your own scales at home!

An off the shelf scale might be a little different. In the scale pictured above, the black wire was actually blue, the red more of an orange color, and the orange wire ended up being the 'center tap' of the strain gauge as opposed to white. I hooked the blue wires to the "B", the orange wires to the "W" and the white wires to the "R".

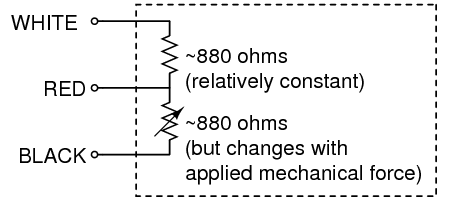

To determine how to hook up your single strain gauge load cells to the combinator, measure the resistance between the three wires. You should find a larger resistance (close to double) between a pair. In our example the resistance between White and Blue was 1.8k Ω, and the resistance between White and Red was 900 Ω. Therefore, the center tap to the strain gauge is the Red wire. The center tap or center pin of your strain gauge connects to the "W" pin on the combinator. The larger resistance wires (White and Blue in this example) connect to the "R" and "B" pins on the combinator.

The combinator board hooks up the four load sensors in such a way that two resistors in the wheatstone bridge configuration are constant values and the other two are variable in this way:

Once you have the combinator board successfully soldered to the twelve wires, you can now connect it to the HX711 amplifier board via the 4 standard load cell wires. You can use short jumper wires or if your electronics are a long distance away from your scale consider using an RJ45 connector and an ethernet cable to connect the combinator to the HX711 amplifier.

Arduino Code

Now that you have your load cell, amplifier, and microcontroller hooked up, you can add your code and start calibrating your setup.

You can download the most up-to-date code and libraries from the link below.

If you have never worked with downloading Arduino libraries or need a quick reminder you might want to take a look at our tutorial on Installing Arduino Libraries.

The first thing you will want to work with is the calibration code: "SparkFun_HX711_Calibration":

language:c

/*

Example using the SparkFun HX711 breakout board with a scale

By: Nathan Seidle

SparkFun Electronics

Date: November 19th, 2014

License: This code is public domain but you buy me a beer if you use this and we meet someday (Beerware license).

This is the calibration sketch. Use it to determine the calibration_factor that the main example uses. It also

outputs the zero_factor useful for projects that have a permanent mass on the scale in between power cycles.

Setup your scale and start the sketch WITHOUT a weight on the scale

Once readings are displayed place the weight on the scale

Press +/- or a/z to adjust the calibration_factor until the output readings match the known weight

Use this calibration_factor on the example sketch

This example assumes pounds (lbs). If you prefer kilograms, change the Serial.print(" lbs"); line to kg. The

calibration factor will be significantly different but it will be linearly related to lbs (1 lbs = 0.453592 kg).

Your calibration factor may be very positive or very negative. It all depends on the setup of your scale system

and the direction the sensors deflect from zero state

This example code uses bogde's excellent library: https://github.com/bogde/HX711

bogde's library is released under a GNU GENERAL PUBLIC LICENSE

Arduino pin 2 -> HX711 CLK

3 -> DOUT

5V -> VCC

GND -> GND

Most any pin on the Arduino Uno will be compatible with DOUT/CLK.

The HX711 board can be powered from 2.7V to 5V so the Arduino 5V power should be fine.

*/

#include "HX711.h"

#define DOUT 3

#define CLK 2

HX711 scale(DOUT, CLK);

float calibration_factor = -7050; //-7050 worked for my 440lb max scale setup

void setup() {

Serial.begin(9600);

Serial.println("HX711 calibration sketch");

Serial.println("Remove all weight from scale");

Serial.println("After readings begin, place known weight on scale");

Serial.println("Press + or a to increase calibration factor");

Serial.println("Press - or z to decrease calibration factor");

scale.set_scale();

scale.tare(); //Reset the scale to 0

long zero_factor = scale.read_average(); //Get a baseline reading

Serial.print("Zero factor: "); //This can be used to remove the need to tare the scale. Useful in permanent scale projects.

Serial.println(zero_factor);

}

void loop() {

scale.set_scale(calibration_factor); //Adjust to this calibration factor

Serial.print("Reading: ");

Serial.print(scale.get_units(), 1);

Serial.print(" lbs"); //Change this to kg and re-adjust the calibration factor if you follow SI units like a sane person

Serial.print(" calibration_factor: ");

Serial.print(calibration_factor);

Serial.println();

if(Serial.available())

{

char temp = Serial.read();

if(temp == '+' || temp == 'a')

calibration_factor += 10;

else if(temp == '-' || temp == 'z')

calibration_factor -= 10;

}

}

Once you have calculated your calibration factor of your load cell set up, you can move on to other code, such as the simple scale output example code, "SparkFun_HX711_Example":

language:c

/*

Example using the SparkFun HX711 breakout board with a scale

By: Nathan Seidle

SparkFun Electronics

Date: November 19th, 2014

License: This code is public domain but you buy me a beer if you use this and we meet someday (Beerware license).

This example demonstrates basic scale output. See the calibration sketch to get the calibration_factor for your

specific load cell setup.

This example code uses bogde's excellent library: https://github.com/bogde/HX711

bogde's library is released under a GNU GENERAL PUBLIC LICENSE

The HX711 does one thing well: read load cells. The breakout board is compatible with any wheat-stone bridge

based load cell which should allow a user to measure everything from a few grams to tens of tons.

Arduino pin 2 -> HX711 CLK

3 -> DAT

5V -> VCC

GND -> GND

The HX711 board can be powered from 2.7V to 5V so the Arduino 5V power should be fine.

*/

#include "HX711.h"

#define calibration_factor -7050.0 //This value is obtained using the SparkFun_HX711_Calibration sketch

#define DOUT 3

#define CLK 2

HX711 scale(DOUT, CLK);

void setup() {

Serial.begin(9600);

Serial.println("HX711 scale demo");

scale.set_scale(calibration_factor); //This value is obtained by using the SparkFun_HX711_Calibration sketch

scale.tare(); //Assuming there is no weight on the scale at start up, reset the scale to 0

Serial.println("Readings:");

}

void loop() {

Serial.print("Reading: ");

Serial.print(scale.get_units(), 1); //scale.get_units() returns a float

Serial.print(" lbs"); //You can change this to kg but you'll need to refactor the calibration_factor

Serial.println();

}

Check out the other example code in the Github repo for powering down the HX711 (github) and known zero startup (github).

Resources and Going Further

Want to know more? Check out this tutorial if you haven't already:

Getting Started with Load Cells

Need even more? Check out this awesome article wheatstone bridges and load cell types.